A kind of mine resource segmental full mining local filling mining method

A mining method and resource technology, applied in the fields of filling, ground mining, mining equipment, etc., can solve the problems of large tunnel section shrinkage, difficulty in achieving high yield and high efficiency, waste of coal resources, etc., and reduce the intensity and deformation of mine pressure. The effect of realizing safe and efficient green mining and eliminating the retention of coal pillars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

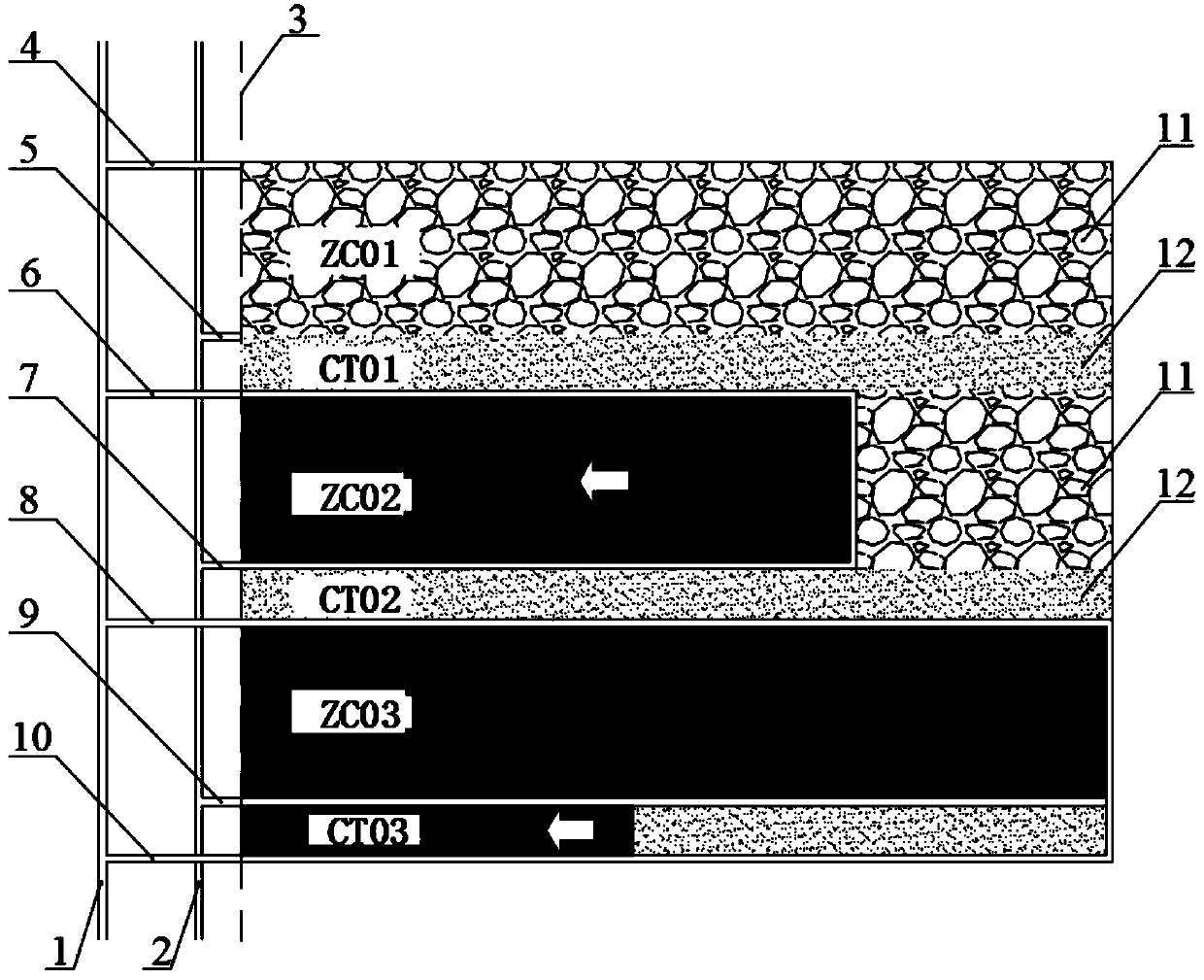

Embodiment 1

[0023] (1) Excavate return air uphill 1 and transport uphill 2 in the mining area, excavate CT01 filling working face transportation level roadway 5, return air level wayway 6 and open cut hole in a coal seam block section to form a complete coal mining production system ;

[0024] (2) mining CT01 to fill the working face, in the process of mining, the gob-side entry is used to process the working face transportation level entry 5 and return air entryway 6, and the supporting wall of the gob-side entry entry is made of piled gangue walls and cemented filling body; CT01 filling face length is 35m, considering the short length of the working face, mining is carried out by roadside cemented filling method. The lane-by-lane cemented filling mining method is specifically to carry out excavation and coal mining in the joint lane between the transport lane and the return air lane of the fully mechanized excavator. After the joint lane is excavated, the cemented filling material is us...

Embodiment 2

[0032] (1) Excavate return air uphill 1 and transport uphill 2 in the mining area, excavate CT01 filling working face transportation level roadway 5, return air level wayway 6 and open cut hole in a coal seam block section to form a complete coal mining production system ;

[0033] (2) mining CT01 to fill the working face, in the process of mining, the gob-side entry is used to process the working face transportation level entry 5 and return air entryway 6, and the supporting wall of the gob-side entry entry is made of piled gangue walls and cemented filling body; CT01 filling face length is 55m, comprehensively considering the working face length, coal seam geology and technical and economic conditions, comprehensive mechanized solid filling mining is adopted. The comprehensive mechanized solid filling mining method is specifically: the coal mining process of the comprehensive mechanized solid filling mining method is the same as the coal mining process of fully mechanized mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com