Mining method for once-mining overall height of gypsum ore deposit

A mining method and full-height mining technology, applied in surface mining, underground mining, special mining, etc., can solve the problems of easy falling, the threat of II gypsum mining room mining, etc., achieving good integrity, simplified labor organization and management, beneficial to The effect of mining balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

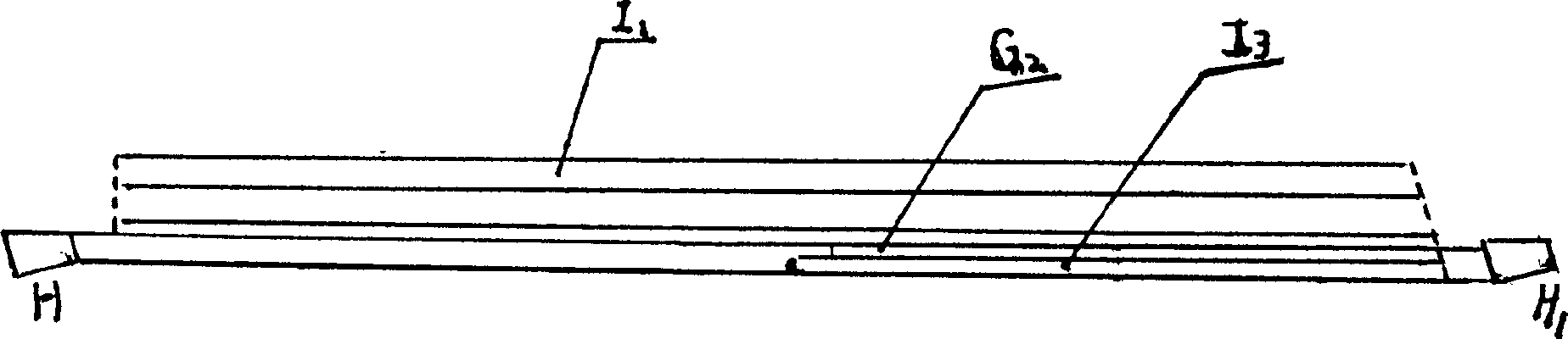

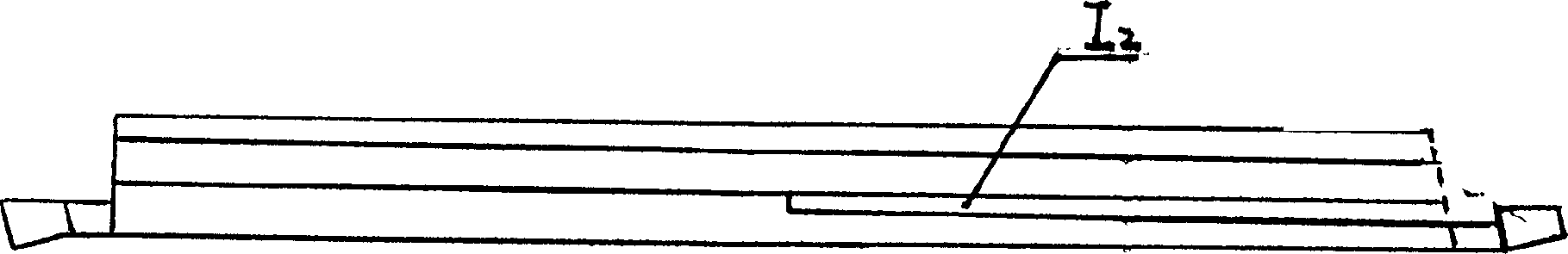

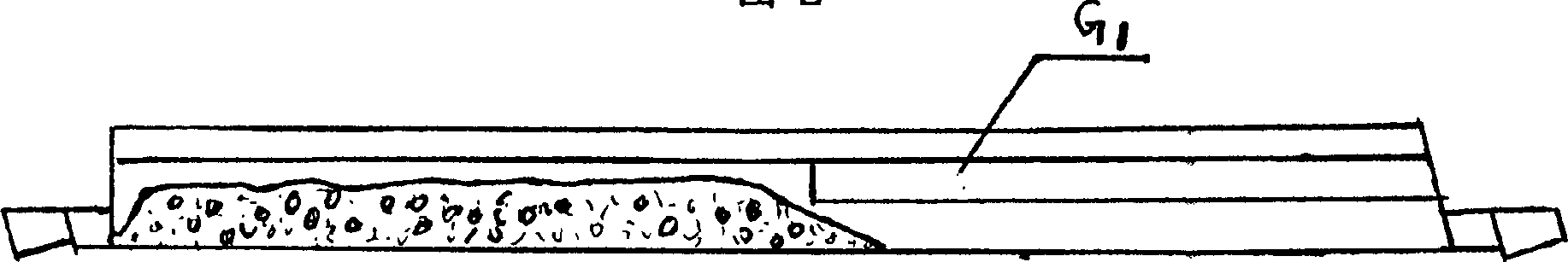

[0020] The present invention only excavates return air alley H and transport alley H in the second gypsum layer (II plaster) 1 , while H 1 It is also used as the return air alley H of the next level. Along the trend every 15 meters in the gray shale G 2 +Gypsum I 3 Digging all eyes in the floor, connecting the return air alley H and the transportation alley H 1 , forming a production system. Also press prior art layering method during exploitation, be divided into the first gypsum layer (I plaster) and the second gypsum layer (II plaster), but the present invention is first in the gray shale G 2 Middle punch shot, pull out gray shale G 2 After loading and transporting away separately, the third gypsum layer I 3 The layer of gypsum is broken down by drilling the hole in the middle 3 (see attached figure 1 ), after the whole mining house is opened enough to be 10 meters wide, in the second gypsum layer I 2 The layer of gypsum is broken down by drilling the hole in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com