Method for filling gas near roadway of coal mine gob-side entry retaining

A technology for gas and coal mines, which is applied to filling materials, mining equipment, earthwork drilling and mining, etc. It can solve the problems of difficult transportation of filling materials, long setting time of filling bodies, and insufficient compressive strength, so as to improve the recovery rate of coal resources and reduce The effect of roadway excavation rate and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

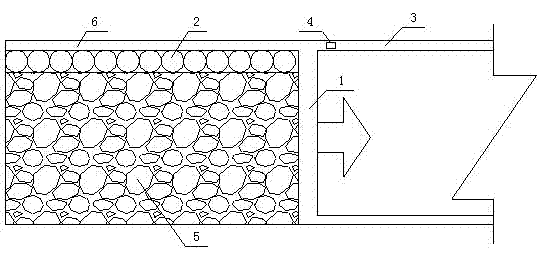

[0021] The gas filling method of the coal mine gobside entry retaining roadway of the present invention firstly sets up a gas booster room near the ground auxiliary shaft, and installs a ground gas booster pump and a high-pressure gas storage tank equipped with 0.8-1Mpa high-pressure gas in the gas booster room ; Then arrange the underground gas booster pump 4 connected to the pipeline of the ground high-pressure gas storage tank in the mining area transportation level roadway 3 of 5-20m in front of the underground coal mining face 1; 5-8m, a cylindrical rubber airbag 2 with the same height as the coal mining height is arranged on the side of the gobside reserved roadway 6 behind the coal mining face 1 near the goaf 5, and the diameter of the cylindrical rubber airbag 2 is equal to its height. The ratio is 0.4 to 0.6; through the pipeline, the downhole gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com