Coal-mining method of high-dipping thick seam

A coal mining method and thick coal seam technology, applied in ground mining, mining equipment, earthwork drilling, etc., can solve the problems of high labor intensity, low recovery rate, and high excavation volume, and achieve good ventilation, less excavation volume, and improved The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is to the 8~10 meter thick coal seam, adopts the coal mining method of double-ditch pseudo-inclined flexible cover bracket, carries out design mining according to the following steps:

[0045] 1. Coal mining method design and applicable conditions

[0046] (1) Coal mining method design:

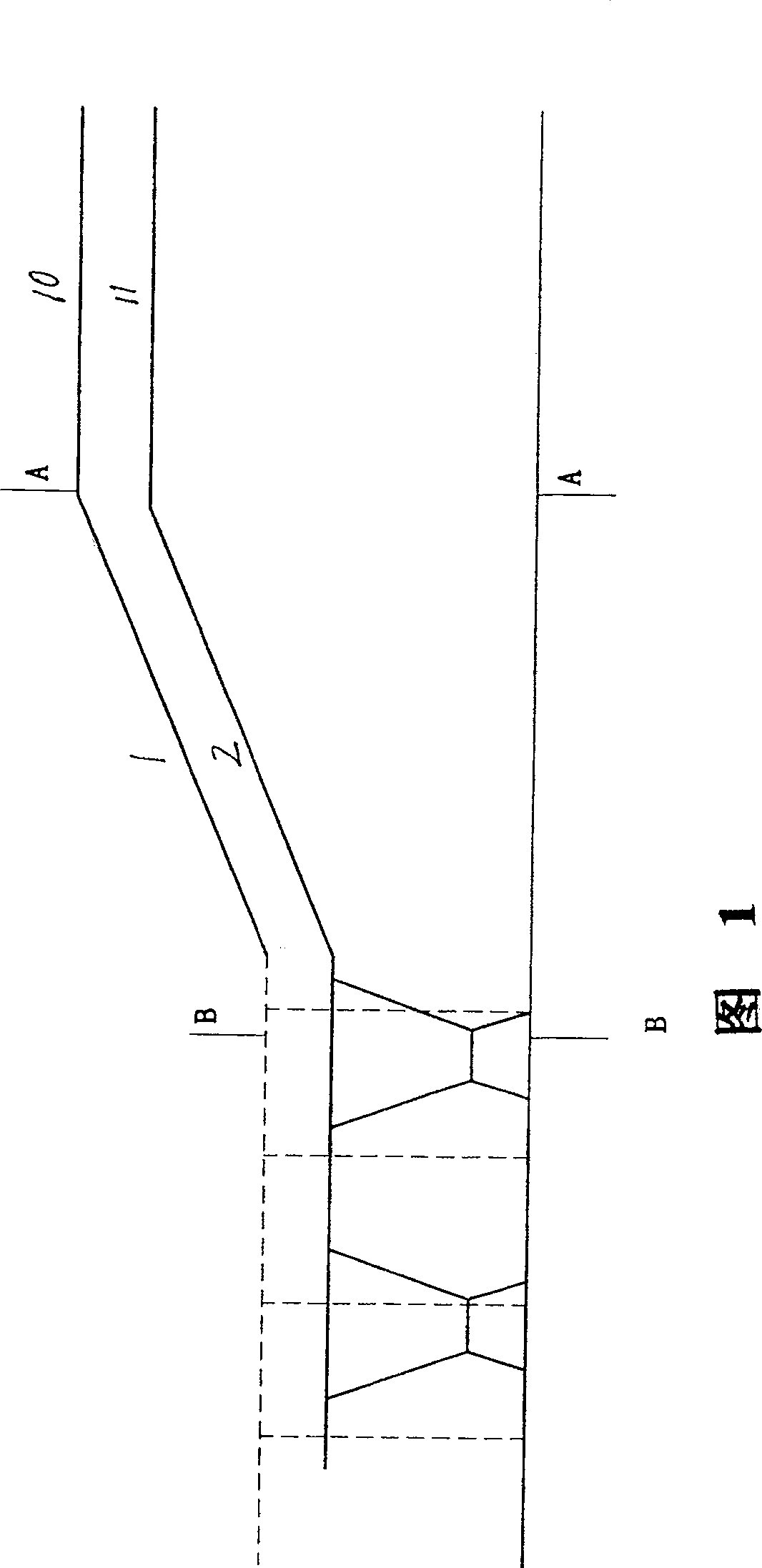

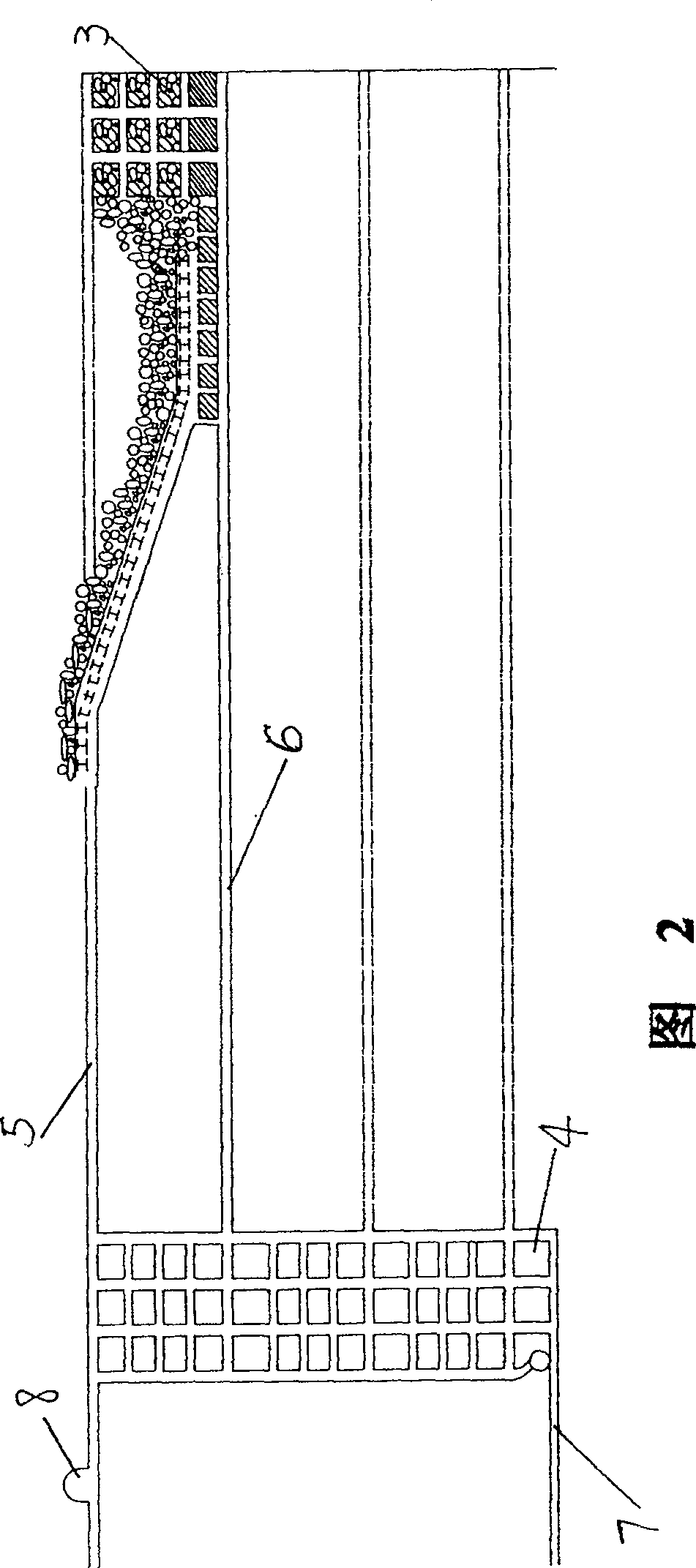

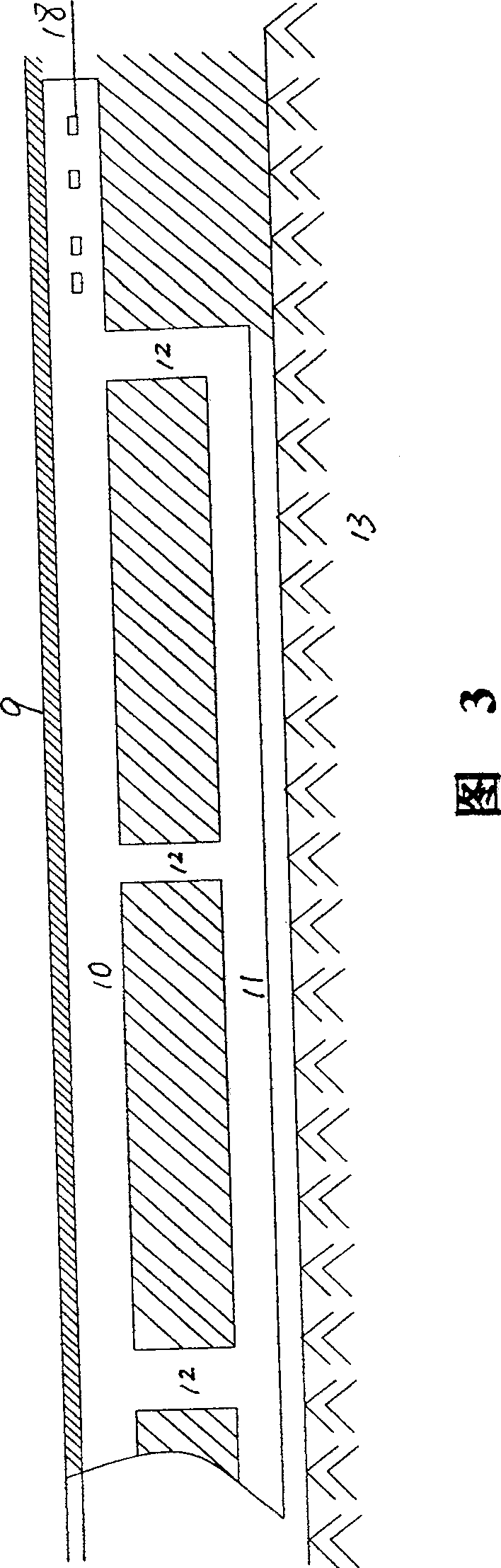

[0047] Referring to Fig. 1, the so-called double ditch means that in a coal seam with a thickness of 8 to 10 meters, two independent flat-type pseudo-inclined flexible shielding supports with a span of 3 meters are arranged along the bottom and roof of the coal seam. , along the bottom is called the bottom ditch 1. Collectively referred to as double ditch. 1.5-2.5 meters between the two ditches isolate the exit of the coal pillar, the bottom ditch communicates with the transport road through the vertical eye, and the coal gate and the fork eye communicate with the transport road. The floor ditch of the upper exit is connected with the upper mountain through ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com