Magnesium alloy compositely forming method

A composite forming and magnesium alloy technology, which is applied in the field of magnesium alloy forgings and magnesium alloy composite forming, can solve the problems of inability to form, fail to meet the requirements of mechanical properties, and limited degree of deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: A magnesium alloy forging is produced by using a magnesium alloy composite forming method and using AZ61 as a raw material. Its process is carried out as follows:

[0024] 1) Magnesium alloy material selection: Magnesium alloy AZ61 is selected as the raw material;

[0025] 2) Preparation of magnesium alloy extrusion billet: AZ61 semi-continuous casting billet with a diameter of Φ100 mm suitable for extrusion equipment requirements was obtained by casting method;

[0026] 3) Preheating before extrusion: heat the cast slab to 380°C and keep the temperature for 80 minutes; at the same time, preheat the extrusion die to 350°C and keep it warm;

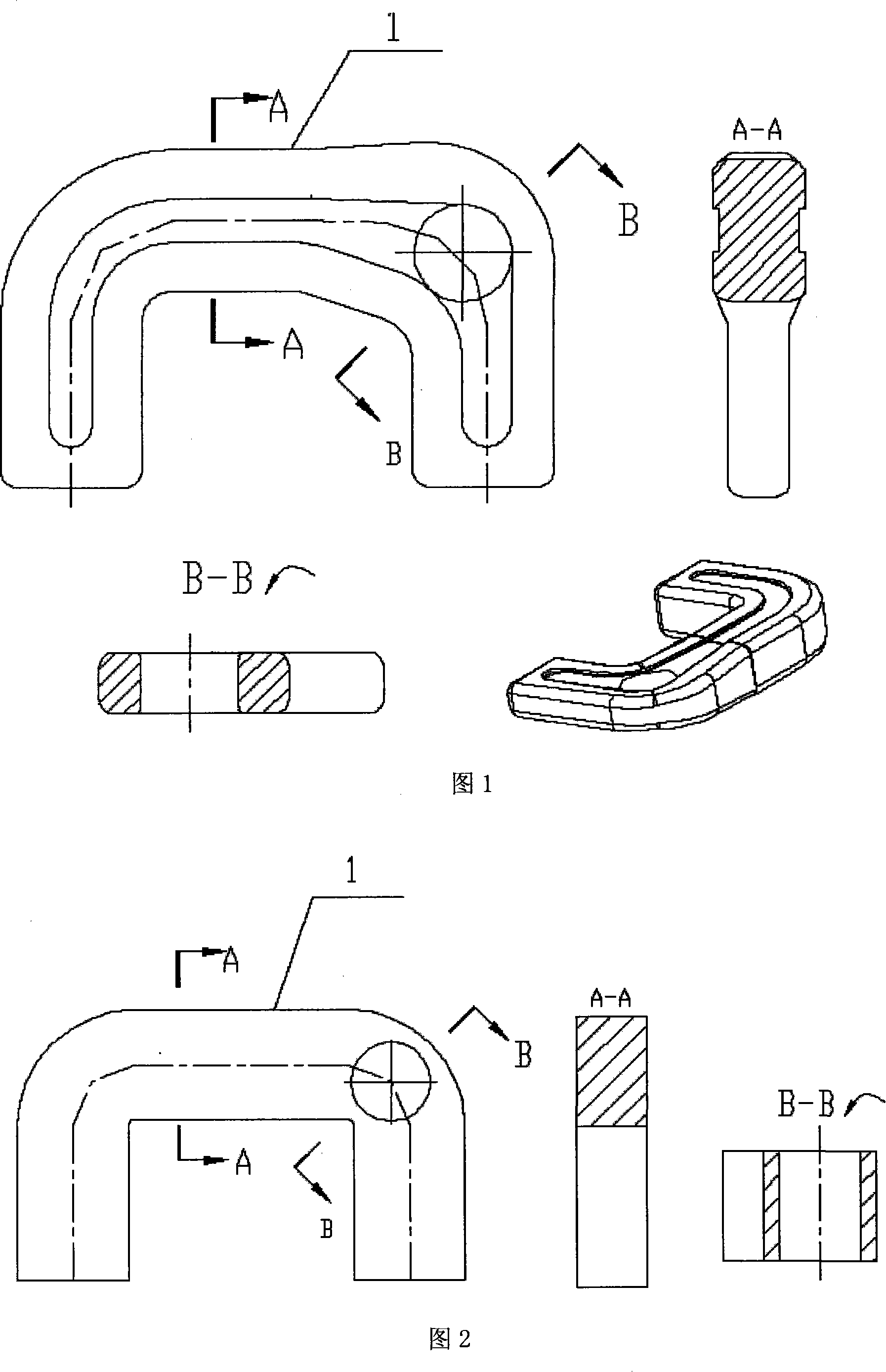

[0027] 4) Extrusion forming: put the billet into the extrusion die, and extrude it at a speed of 2.5m / min to form a preformed section with two-dimensional geometric characteristics of the forging (see Figure 2);

[0028] 5) Prepare molded blanks: cut the extruded profiles into 14 mm long molded blanks according to the d...

Embodiment 2

[0031] Example 2: A magnesium alloy forging is produced by using a magnesium alloy composite forming method and using AZ31 as a raw material. Its process is carried out as follows:

[0032] 1) Magnesium alloy material selection: Magnesium alloy AZ31 is selected as the raw material;

[0033] 2) Preparation of magnesium alloy extrusion billet: AZ31 semi-continuous casting billet with a diameter of Φ100mm suitable for extrusion equipment requirements was obtained by casting method;

[0034] 3) Preheating before extrusion: heat the cast slab to 425°C and keep the temperature for 120 minutes; at the same time, preheat the extrusion die to 316°C and keep it warm;

[0035] 4) Extrusion forming: put the billet into the extrusion die, and extrude it at a speed of 12m / min to form a preformed section with two-dimensional geometric characteristics of the forging (see Figure 2);

[0036] 5) Prepare molded blanks: cut the extruded profiles into 14 mm long molded blanks according to the de...

Embodiment 3

[0039] Example 3: A magnesium alloy forging was produced using a magnesium alloy composite forming method with AZ80 as the raw material. Its process is carried out as follows:

[0040] 1) Magnesium alloy material selection: Magnesium alloy AZ80 is selected as the raw material;

[0041] 2) Preparation of magnesium alloy extrusion billet: AZ80 semi-continuous casting billet with a diameter of Φ100 mm suitable for extrusion equipment requirements is obtained by casting method;

[0042] 3) Preheating before extrusion: heat the cast slab to 400°C and keep the temperature for 25 minutes; at the same time, preheat the extrusion die to 288°C and keep it warm;

[0043] 4) Extrusion forming: put the billet into the extrusion die, and extrude it at a speed of 7m / min to form a preformed section with the two-dimensional geometric characteristics of the forging (see Figure 2);

[0044] 5) Prepare molded blanks: cut the extruded profiles into 14 mm long molded blanks according to the desig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com