Method of mining coal from heavy pitch thick coal seam

A coal mining method and thick coal seam technology, applied in ground mining, earth drilling, underground mining, etc., can solve the problems of inability to carry out independent negative pressure ventilation, no two outlets, and thin coal seam thickness, so as to reduce tunneling efficiency, increased yield and efficiency, and the effects of increased yield and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

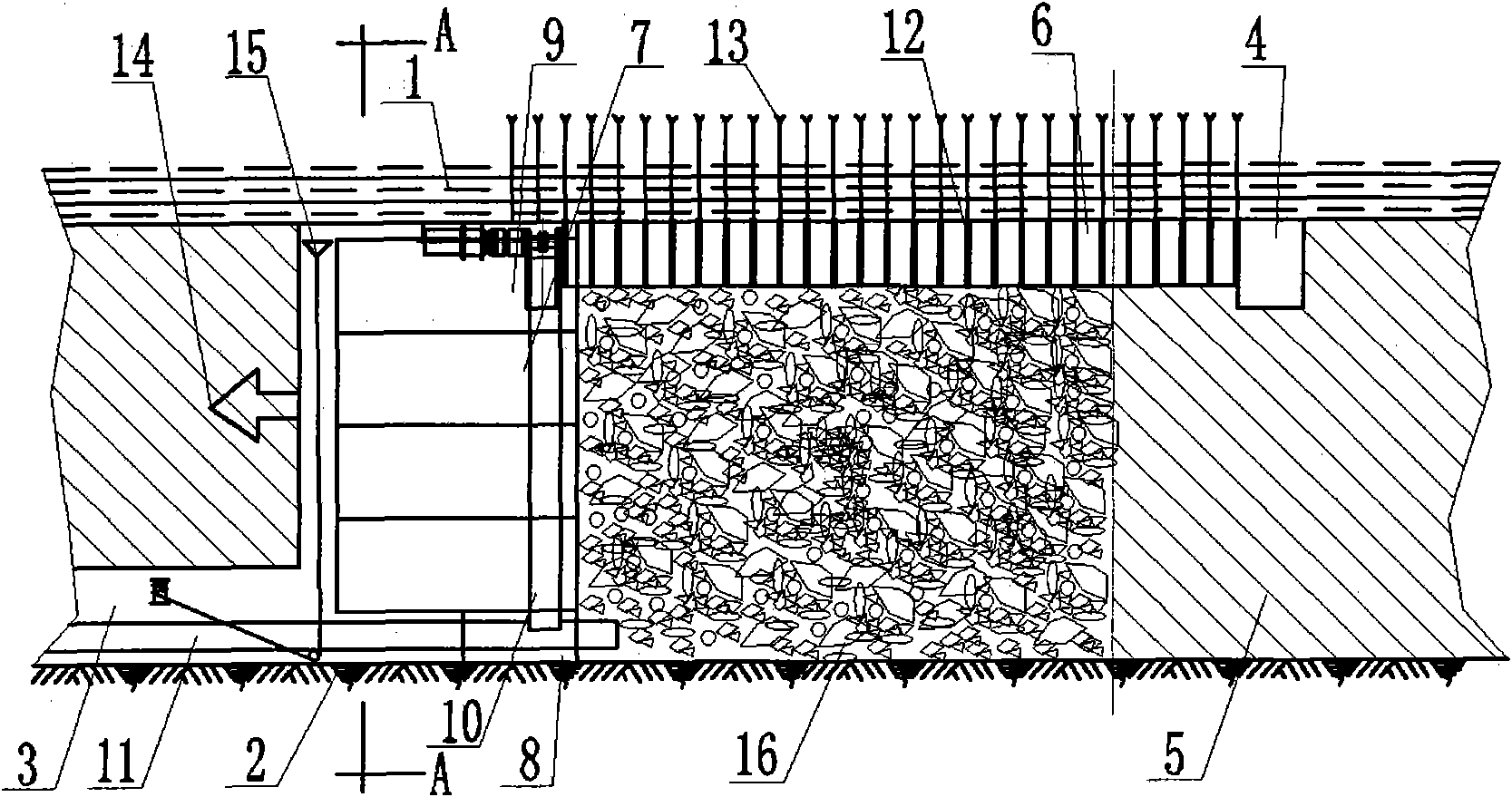

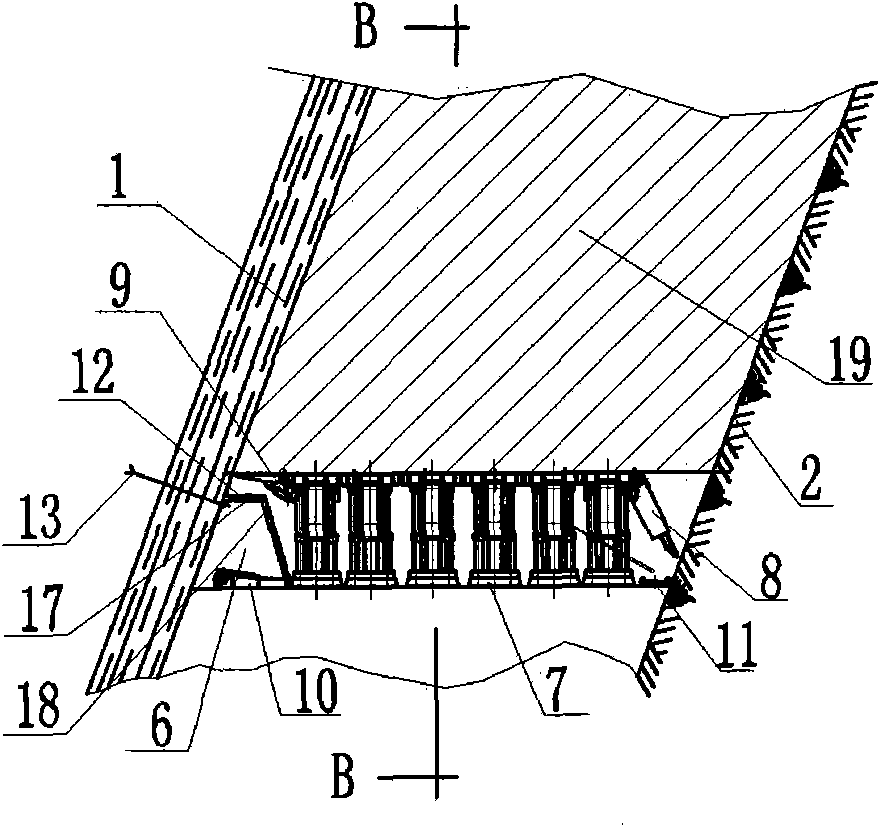

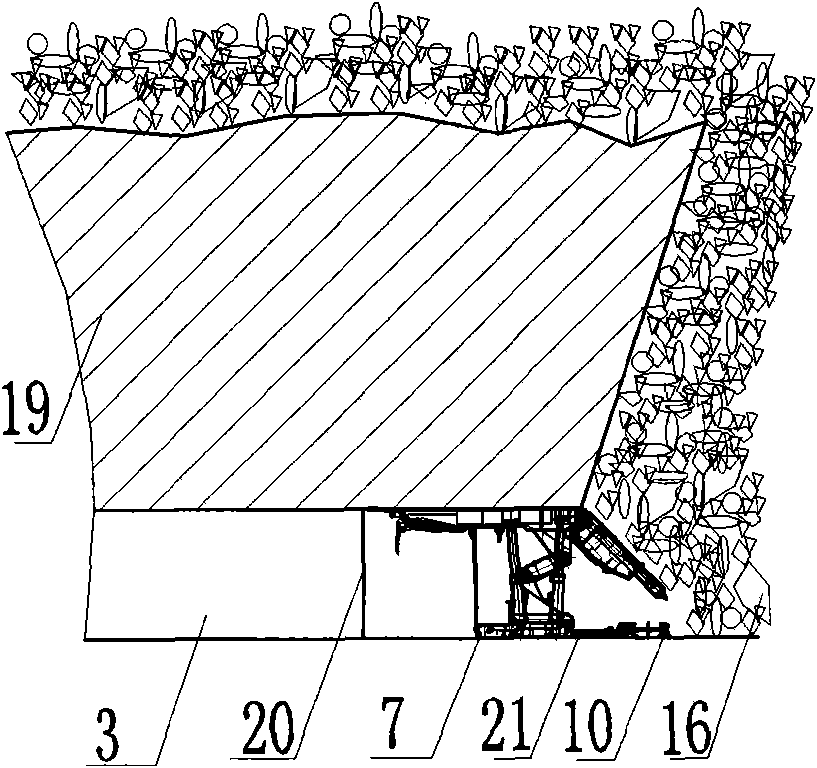

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] figure 1 , figure 2 and image 3 Among them, the transportation lane 3 and the air return lane 6 are arranged at the bottom of the stage, and a working face is formed between them. The working face is arranged in a "Z" shape, and the stage height can be between 8 and 12m, and the mining height of the working face should not be lower than 2.5m. The working face advances from the boundary of Shangshan Coal Pillar 5. The top-coal caving hydraulic support 7 and the top-coal caving hydraulic supports 8 and 9 at both ends are arranged along the working face, and there is one top-coal caving hydraulic support 8 and 9 at both ends, and the number of the top-coal caving hydraulic supports 7 is determined by the length of the working face . Because the length of the working face is short, drilling and blasting are used to drop coal, and the cycle pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com