Method for recycling iron phosphate and lithium carbonate from lithium iron phosphate waste

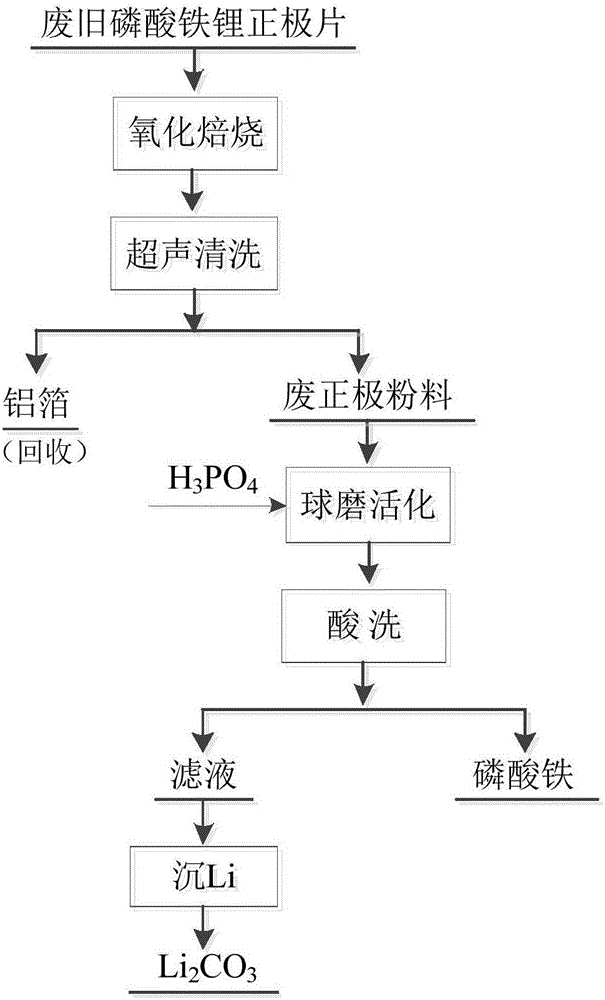

A technology of lithium iron phosphate and iron phosphate, which is applied in the field of battery waste resource recycling, can solve the problems of large consumption of reagents, complicated process steps, and many process steps, and achieves high product value, low reagent consumption, and simple projection system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1, oxidation roasting: put the tray containing 1 kg of discarded lithium iron phosphate positive electrode into the roasting furnace, heat to 450 ° C, and roast for 3.5 hours to make the binder PTFE invalid and the conductive agent carbon black to volatilize, take out the tray, Obtain the positive electrode piece calcined material containing lithium iron phosphate active material and current collector aluminum foil, wherein the reaction principle is: 6LiFePO 4 +3 / 2O 2 =2Li 3 Fe 2 (PO 4 ) 3 +Fe 2 o 3 ;

[0029] Step 2, pole piece cleaning: put the positive pole piece baked in step 1 into an ultrasonic cleaning tank after it is cooled to 25°C, and after ultrasonic cleaning for 30 minutes, take out the aluminum foil for recovery (at this time, the positive electrode material on the aluminum foil has completely fallen off), filter The lithium iron phosphate active material in the cleaning solution is used for standby, and the filtrate is circulated as the cleani...

Embodiment 2

[0034] Step 1, oxidation roasting: Put the tray containing 1 kg of discarded lithium iron phosphate positive electrode into the roasting furnace, heat to 400°C, and roast for 3.5 hours to make the binder PTFE invalid, and the conductive agent carbon black volatilize, take out the tray, Obtain the positive electrode plate roasting material containing lithium iron phosphate active material and current collector aluminum foil;

[0035] Step 2, pole piece cleaning: put the positive pole piece baked in step 1 into an ultrasonic cleaning tank after it is cooled to 25°C, and after ultrasonic cleaning for 30 minutes, take out the aluminum foil for recovery (at this time, the positive electrode material on the aluminum foil has completely fallen off), filter The lithium iron phosphate active material in the cleaning solution is used for standby, and the filtrate is circulated as the cleaning solution for the next batch of materials;

[0036] Step 3: Add phosphoric acid ball milling to ...

Embodiment 3

[0040] Step 1, oxidation roasting: Put the tray containing 1 kg of discarded lithium iron phosphate positive electrode into the roasting furnace, heat to 500 ° C, and roast for 4 hours to make the binder PTFE invalid, the conductive agent carbon black volatilize, take out the tray, and get Positive plate firing material containing lithium iron phosphate active material and current collector aluminum foil;

[0041] Step 2, pole piece cleaning: put the positive pole piece baked in step 1 into an ultrasonic cleaning tank after it is cooled to 25°C, and after ultrasonic cleaning for 60 minutes, take out the aluminum foil for recovery (at this time, the positive electrode material on the aluminum foil has completely fallen off), filter The lithium iron phosphate active material in the cleaning solution is used for standby, and the filtrate is circulated as the cleaning solution for the next batch of materials;

[0042] Step 3, positive electrode material plus phosphoric acid ball m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com