Large-structure sublevel drilling stage ore removal mining method with delayed filling

A filling mining method and a large-scale structure technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of large cutting engineering, waste of ore resources, and large consumption of personnel and equipment, and achieve production scheduling and management. Simple, solve the effect of high engineering maintenance costs and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

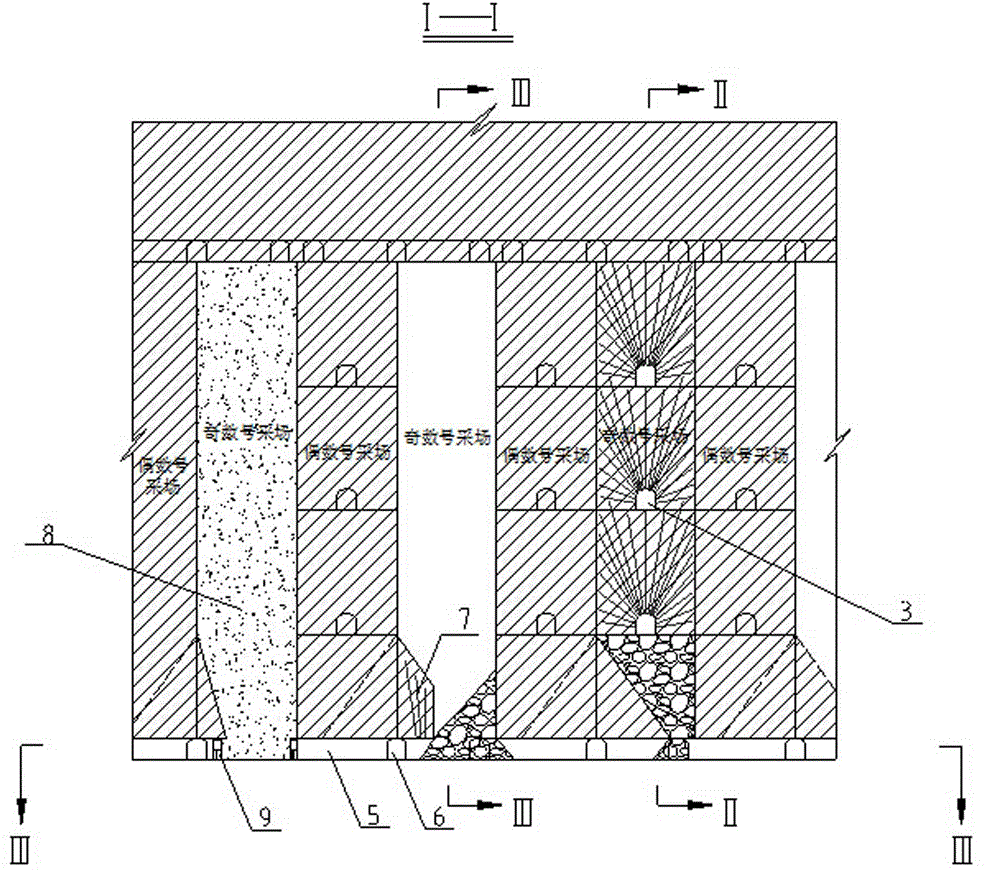

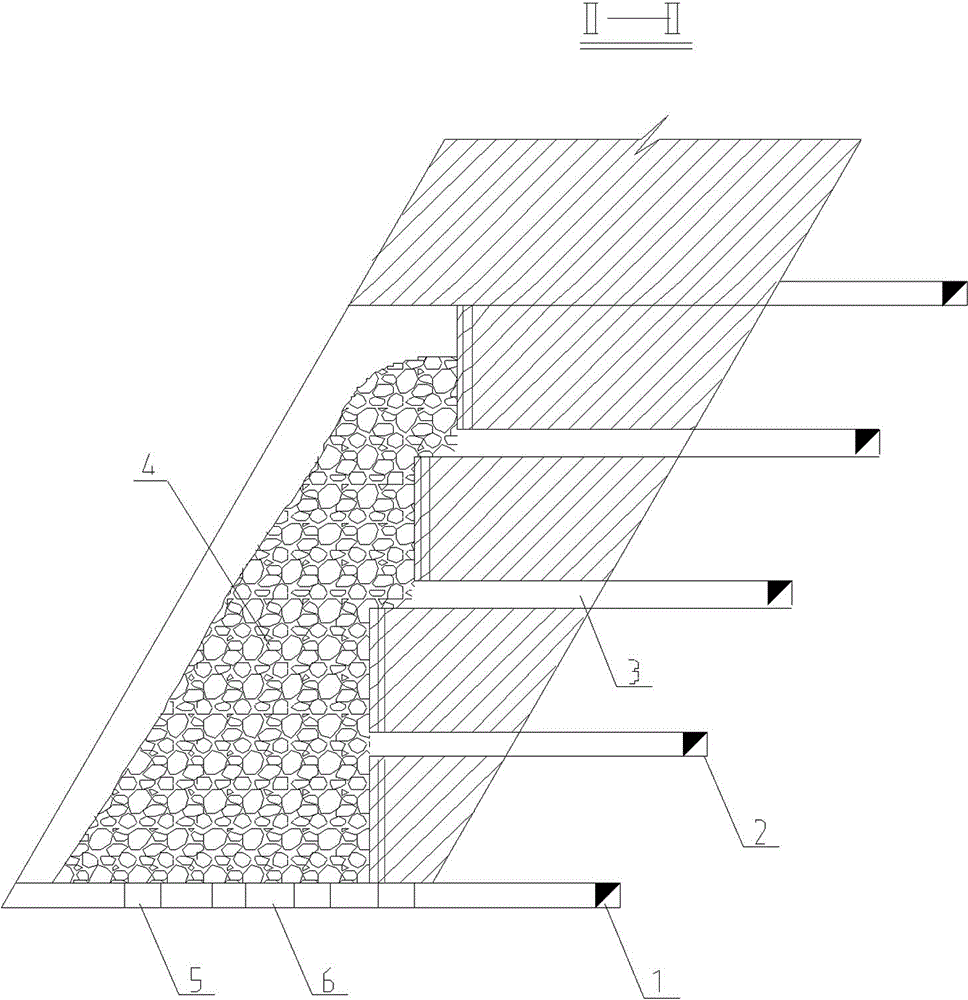

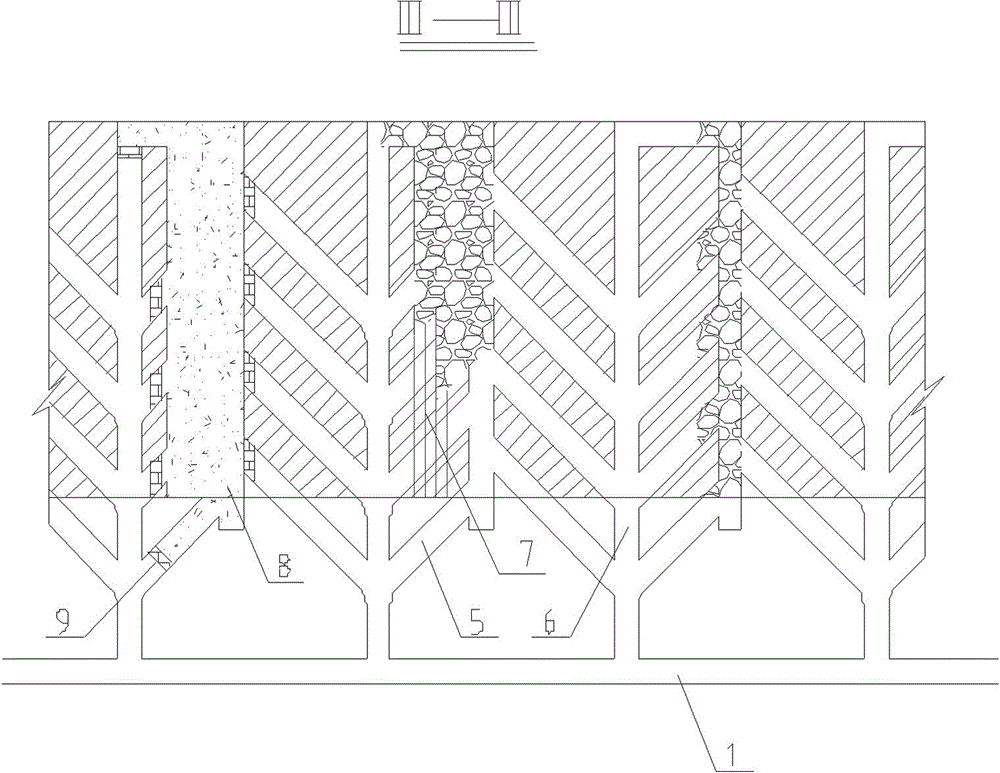

[0024] see figure 1 , figure 2 , image 3 and Figure 4 , the ore body is divided into odd-numbered stopes and even-numbered stopes along the strike, and according to the structural parameters of the middle section height of 100m, the stope span of 20m, and the section height of 25m, the middle section of the transportation roadway, segmented roadway, chisel Mining and cutting projects such as rock roadway, ore-piercing vein, ore-exit approach. Mining can begin after the mining and cutting works are completed. During mining, the first step is to mine the odd-numbered stopes, and the gobs will not be filled; the second step is to mine the 1 / 2 bottom structure corresponding to the odd-numbered stopes. goaf and its bottom structure; in the third step, the even-numbered stope is mined, and the goaf is not filled; in the fourth step, the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com