Apparatus for integrated treatment and comprehensive utilization of wastewater and use thereof

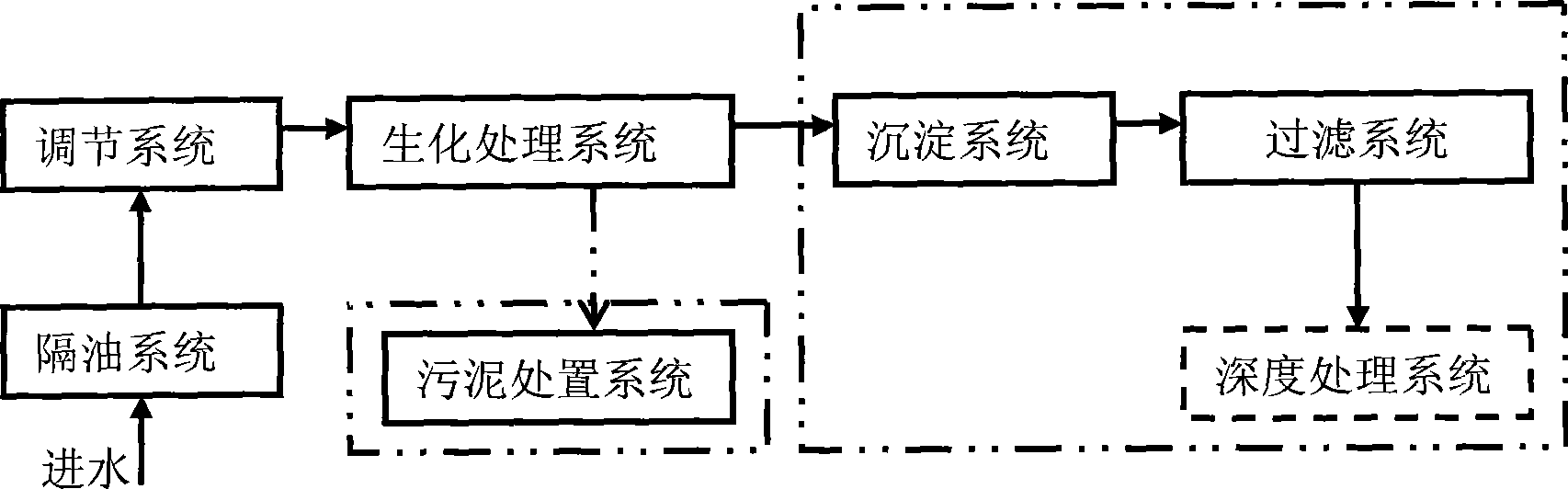

A biochemical treatment tank and wastewater technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of no comprehensive utilization, low controllability, and wastewater Incorporate problems such as comprehensive sewage plants to achieve the effect of preventing blockage and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

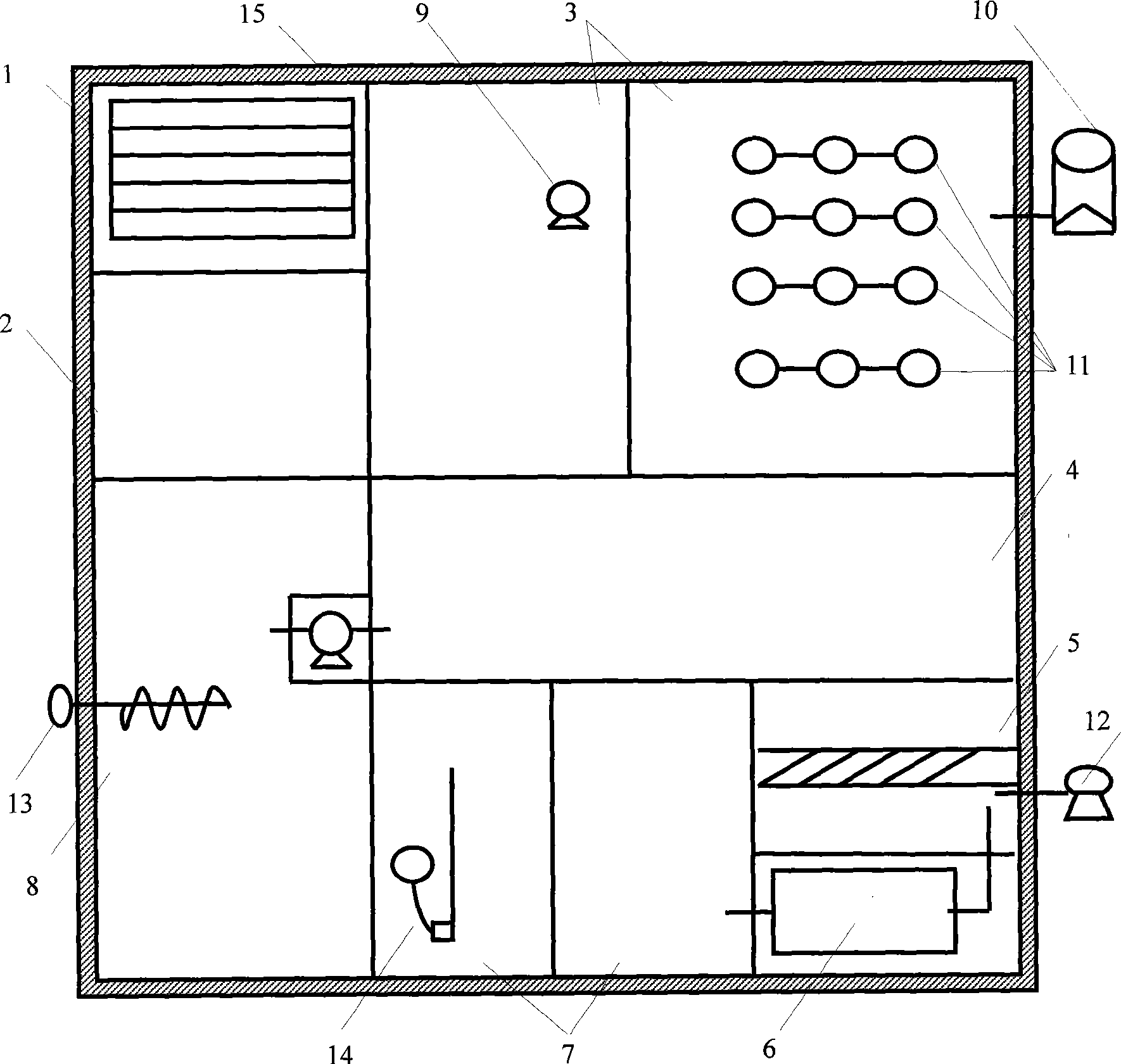

[0070] Example 1: Integrated treatment and reuse of comprehensive sewage in a machinery factory

[0071] A machinery factory built a new factory building, and the new factory building area does not have the conditions to receive sewage for the time being, and the comprehensive sewage needs to be treated before reuse. Its sewage discharge is about 25t / d, wastewater parameters pH: 6.5-8; COD: 200-600mg / L; BOD: 100-300mg / L; ammonia nitrogen: 30-50mg / L; SS: 100-300mg / L; Wastewater contains a lot of oil. For the waste water integrated treatment and reuse device provided by the present invention, please refer to the attached figure 2 , its equipment and technological process are as follows:

[0072] (1) Wastewater enters the integrated equipment, which is made of carbon steel, and the outer layer of the equipment is equipped with an insulation layer made of polyurethane sandwich panels. The design wastewater treatment capacity is 30t / d. The waste water first passes through the ...

Embodiment 2

[0076] Example 2: Integrated treatment and comprehensive utilization of wastewater from a restaurant

[0077] A restaurant located in a scenic area produces wastewater of about 15t / d, pH: 6-8; COD: 1000~1600mg / L; ammonia nitrogen: 100~150mg / L; SS: 20~250mg / L, in the wastewater Contains a lot of animal and vegetable oils. Utilize technique and equipment of the present invention to carry out the technological process of wastewater treatment as follows:

[0078] (1) Wastewater enters the integrated equipment, which is made of glass fiber reinforced plastics, and the outer layer of the equipment is equipped with a polystyrene sandwich panel insulation layer. Its design capacity is 10t / d. Sewage first passes through the inclined plate grease trap to remove animal and vegetable oils on the surface of the wastewater, with a removal rate of 65-80%. Grease is collected regularly and delivered away. The wastewater then enters the adjustment tank, and the pH is adjusted to 6-8 by add...

Embodiment 3

[0082] Example 3 Integrated treatment and resource utilization of comprehensive wastewater in a new school

[0083] A newly built school produces about 90t / d of comprehensive wastewater, pH: 6-8; COD: 450-700mg / L; ammonia nitrogen: 150-300mg / L; SS: 150-400mg / L. Wastewater contains a large amount of edible oil. Utilize technique and equipment of the present invention to carry out the technological process of wastewater treatment as follows:

[0084] (1) Wastewater enters the integrated equipment pool made of carbon steel, and the surface of the equipment is equipped with an insulation layer of rock wool sandwich panel material. Its design sewage treatment capacity is 100t / d. The waste water first passes through the flat grease trap to remove more than 60% of the grease, and is collected and recycled regularly; then it enters the regulating pool to adjust the pH and water volume.

[0085](2) The waste water then enters the MBR biochemical treatment tank equipped with a membra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com