Process and device for recovering electrolytic copper from copper-containing wastewater

A technology for electrolysis of copper and wastewater, applied in the fields of metallurgical wastewater treatment, water pollutants, water/sewage treatment, etc., can solve the problems of difficult to remove impurities in concentrated liquid, accumulation of harmful impurities in tank liquid, etc., and achieve high economic value and resource recovery. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

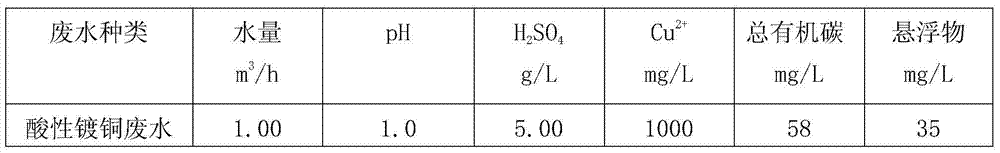

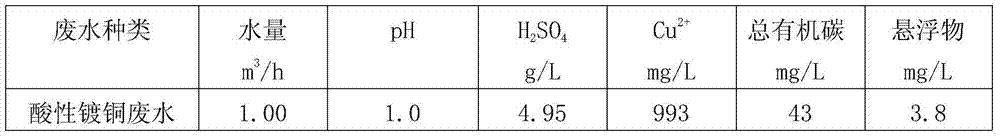

[0027] Using the device in Example 2, the copper-containing waste water first enters the sump 1, and after the sump is preliminarily settled, it is pumped by a centrifugal pump by 1m 3 The flow rate of / h is sent to the bag filter 2 to filter and remove solid impurities, and then enters the activated carbon sand filter column 3 for purification. The activated carbon uses coconut shell activated carbon with a particle size of 3-5mm and an iodine value of 800-1000. The wastewater meets the purification requirements, and the suspended matter in the wastewater is ≦5mg / L. The detection values are shown in Table 2:

[0028] Table 2

[0029]

[0030] The waste water treated by the activated carbon sand filter column 3 enters the first transfer tank 4, and then presses the centrifugal pump by 1m 3 The flow rate of / h is sent into the first exchange column 5 and the second exchange column 6 equipped with macroporous adsorption resin, and the first exchange column 5 is equipped wi...

Embodiment 2

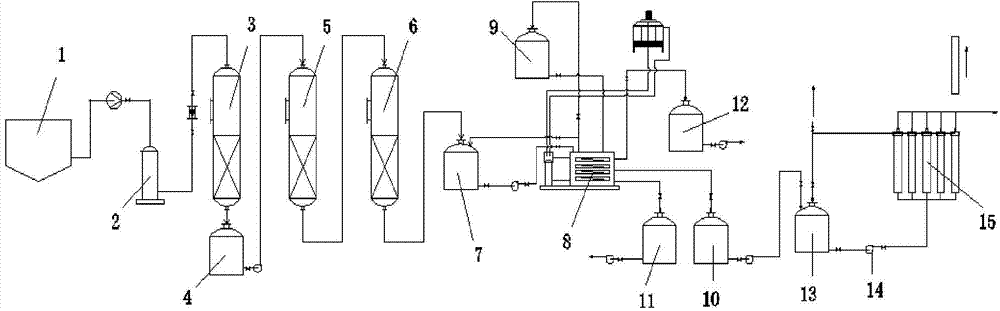

[0040] Such as figure 1 , a device for realizing the process of recovering electrolytic copper from copper-containing wastewater, including a pre-treatment unit, a membrane system treatment unit and an electrolytic copper production unit: the pre-treatment unit includes a water collection tank 1, a bag filter 2, an activated carbon sand filter column 3, The first transfer tank 4, the first exchange column 5, the second exchange column 6, and the second transfer tank 7, wherein the outlet of the water collection tank 1 is connected to the inlet of the bag filter 2, and the outlet of the bag filter 2 is connected to the inlet of the activated carbon sand filter column 3 , the activated carbon sand filter column 3 is connected to the inlet of the first exchange column 5 through the first transfer tank 4, the first exchange column 5 and the second exchange column 6 are connected in series, and the outlet of the second exchange column 6 is connected to the membrane system through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com