Fluorine double-inlet vertical fluorination reactor and use method thereof

A reactor, dual-entry technology, applied in chemical instruments and methods, reactors, manufacturing reactors, etc., can solve the problems of lack of fluorinated ash and slag processing technology, difficult storage of fluorinated ash and slag, etc., and achieve considerable economic and environmental benefits. Significant, yield-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

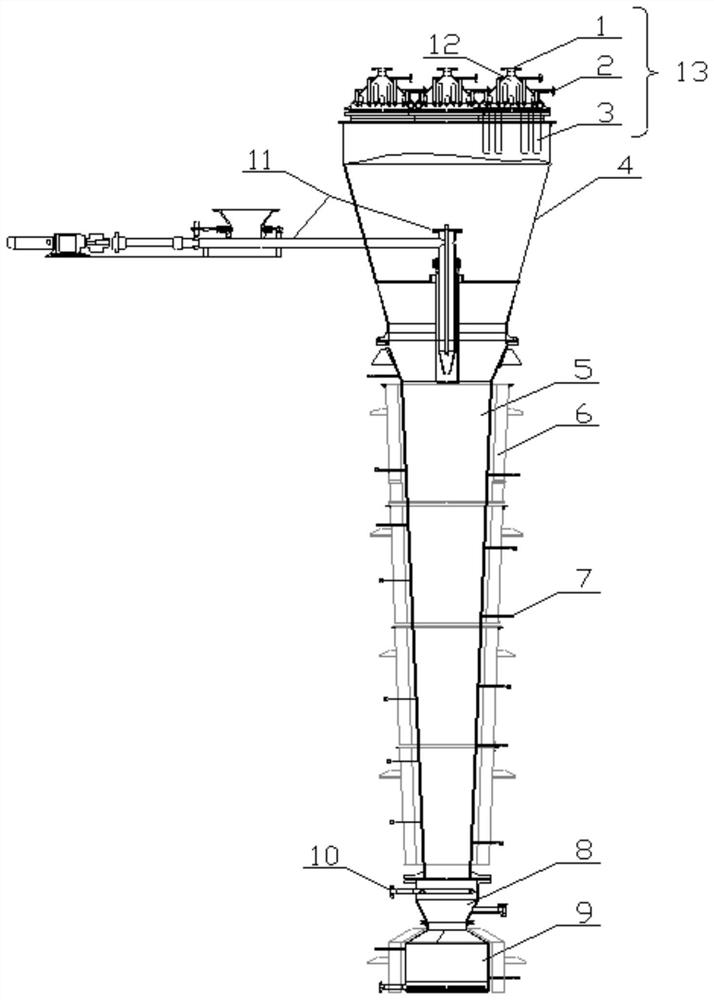

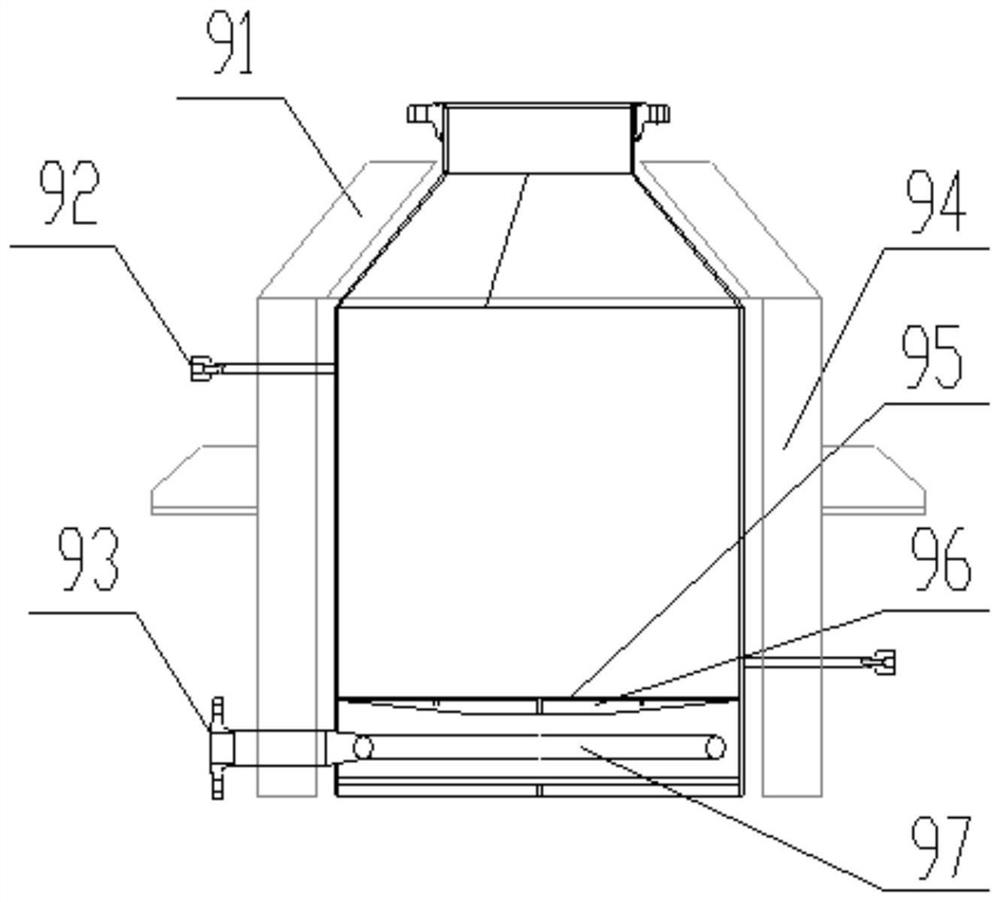

[0032]A kind of fluorine gas double inlet vertical fluorination reactor, comprising a fluorination reactor body 5, the fluorination reactor body 5 above the fluorination reactor enlargement section 4 and the fluorination reactor feed device 11, wherein the fluorination reactor feed device 11 comprises a horizontally mounted feed screw conveyor and a vertically mounted center feeding tube, wherein the central discharge pipe is located inside the fluorination reactor enlargement section 4, the upper part of the fluorination reactor enlargement section 4 is connected to the filter 13, the filter 13 is provided within the filter 3 and the nitrogen blowback device 12, Nitrogen blowback device 12 with nitrogen inlet 2, nitrogen inlet 2 and filter tube 3 communication, for nitrogen into the filter tube backflushing, in order to remove the solid material adhered to the filter tube 3, nitrogen blowback device 12 is also provided above the uranium hexafluoride gas outlet 1, uranium hexafluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com