Technology for preventing and treating coal seam roof water damage through dynamic pressure maintaining grouting blocking fissures of horizontal long drill holes in mining fractured zone

A coal seam roof and fissure zone technology, which is used in earth-moving drilling, sealing/packing, wellbore/well components, etc. It is difficult to control and other problems, so as to reduce the influx of roof water into the mine, improve the recovery rate of coal resources, and reduce the threat of roof water damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation of the present invention will be further analyzed and described below in conjunction with the accompanying drawings and specific examples.

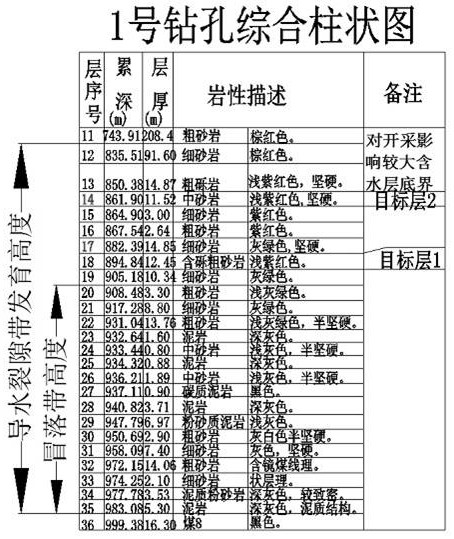

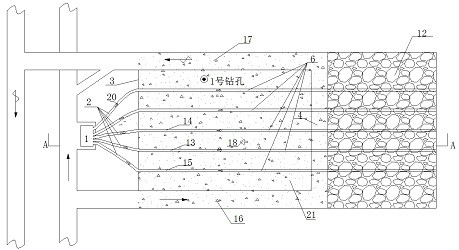

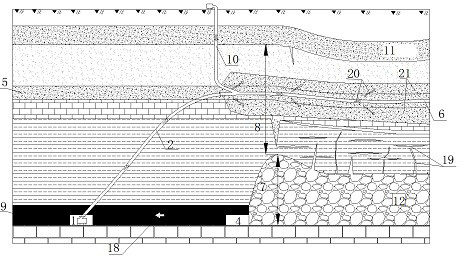

[0027] The present invention is a comprehensive technical method for water prevention and control of horizontal long borehole pressure maintaining and dynamic grouting in the mining fracture zone. According to the hydrogeology of the mining area and the development characteristics of the height of the water-conducting fracture zone in the mining overlying rock under specific mining conditions, the evaluation is carried out. The risk of overlying aquifers during coal seam mining is determined, the overlying aquifers that have a greater impact on mining are delineated, and the horizons of each target layer in the overlying rock are calibrated. Then, according to the layout of the coal mining face, the construction capacity of the drilling rig, the lithology of the overlying strata and the development boundary of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com