Coal mining method for high-dipping low seam

A coal mining method and a technology of steep inclination, applied in the field of coal mining in steeply inclined thin coal seams, can solve the problems of inability to realize mechanized mining, high labor intensity, low efficiency, etc., so as to improve the recovery rate of mine resources, increase unit yield and efficiency, and output and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

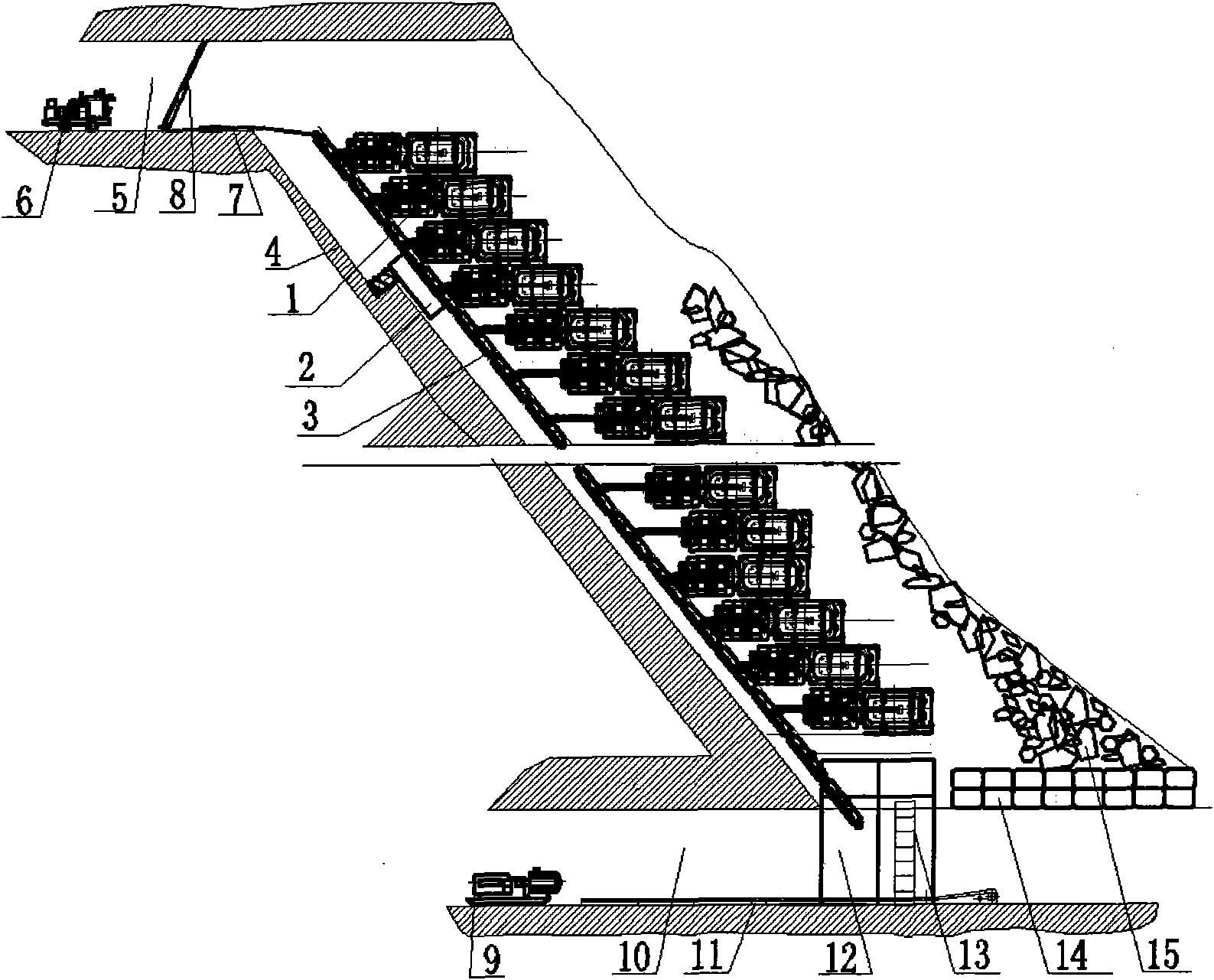

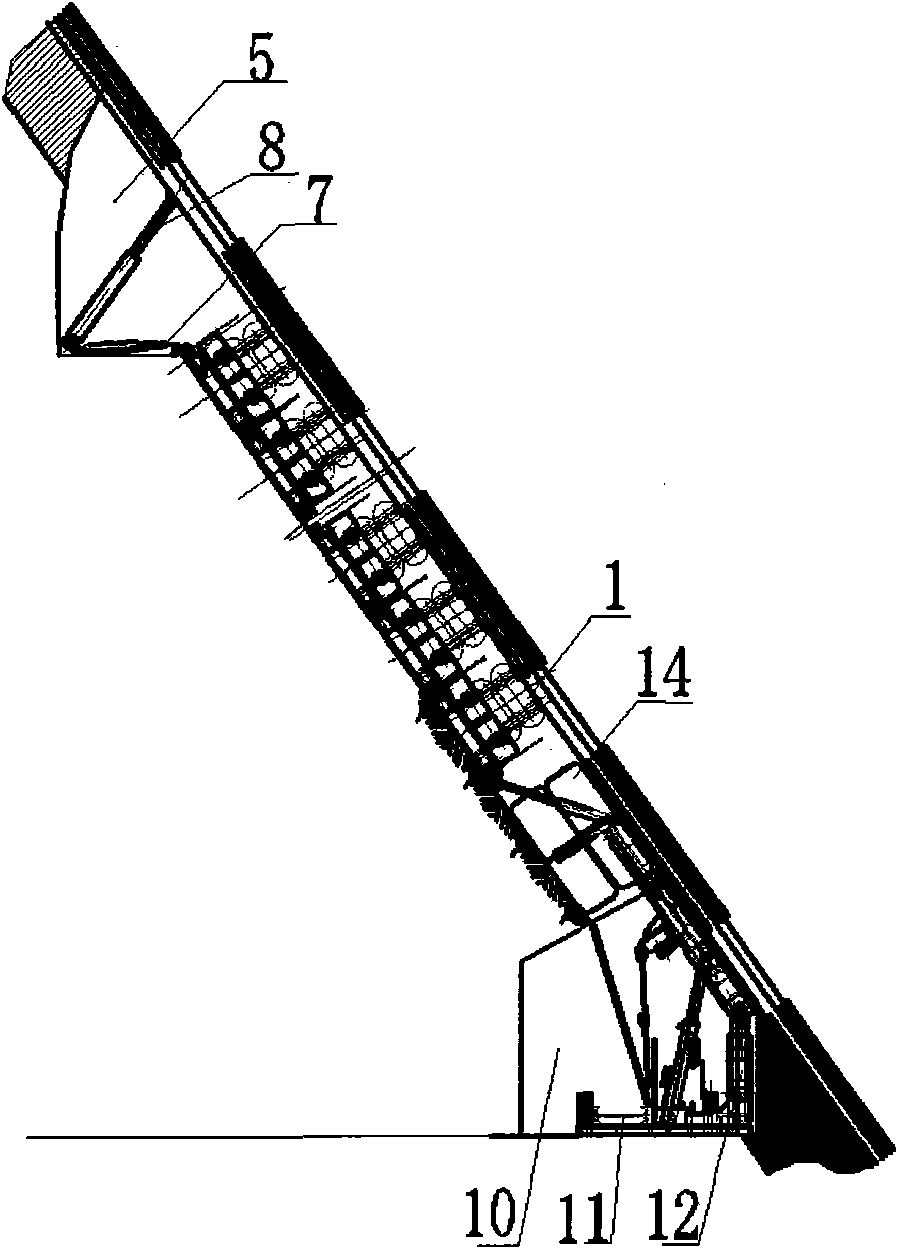

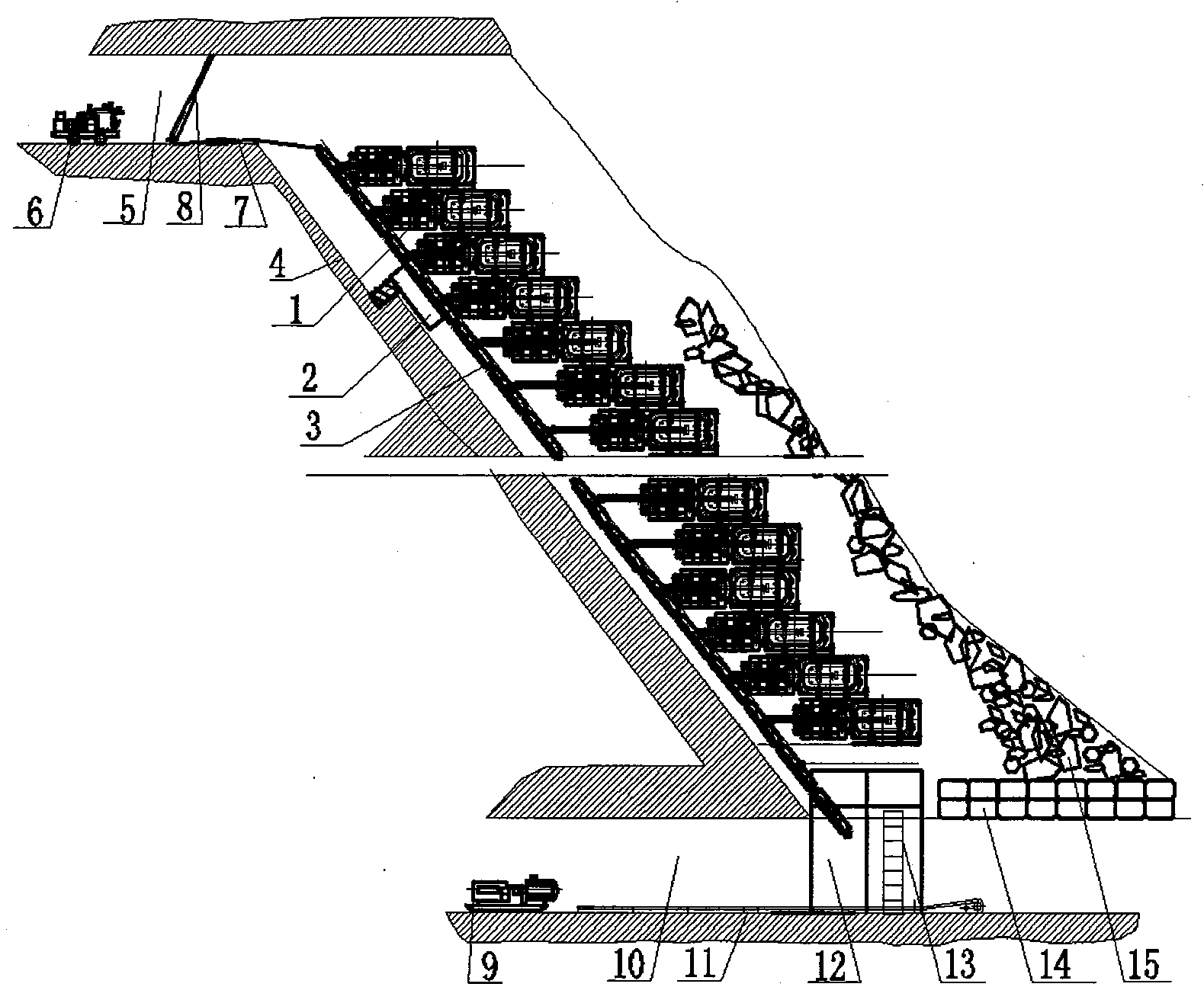

[0012] exist figure 1 and figure 2 In the process, the coal shearer 2 drops coal along the rack rail of the walking beam 3, firstly cuts off the coal wall 4 by a cycle step of the working face, then pushes the walking beam 3 forward by one step, and then moves the step The beam 3 is a support, and the air stack support 1 is moved forward by one step in sequence. The walking beam 3 is pulled by the suspension jack 7 arranged in the return air lane 5 of the working face, which can prevent the walking beam 3 from sliding down; the suspension jack 7 is anchored by the anchor column 8. As the working face advances, goaf filling is carried out from the air return lane 5 of the working face. At the lower end of the working face, along with the advancement of the working face, filling is carried out along the transport lane 10 of the working face.

[0013]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com