Mining method employing solid filling and fully-mechanized coal mining hybrid working face

A technology of solid filling and mining methods, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of complex process and low unit yield and single efficiency of solid filling working face, so as to reduce environmental pollution, improve the recovery rate of coal resources, The effect of solving the requirement of output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

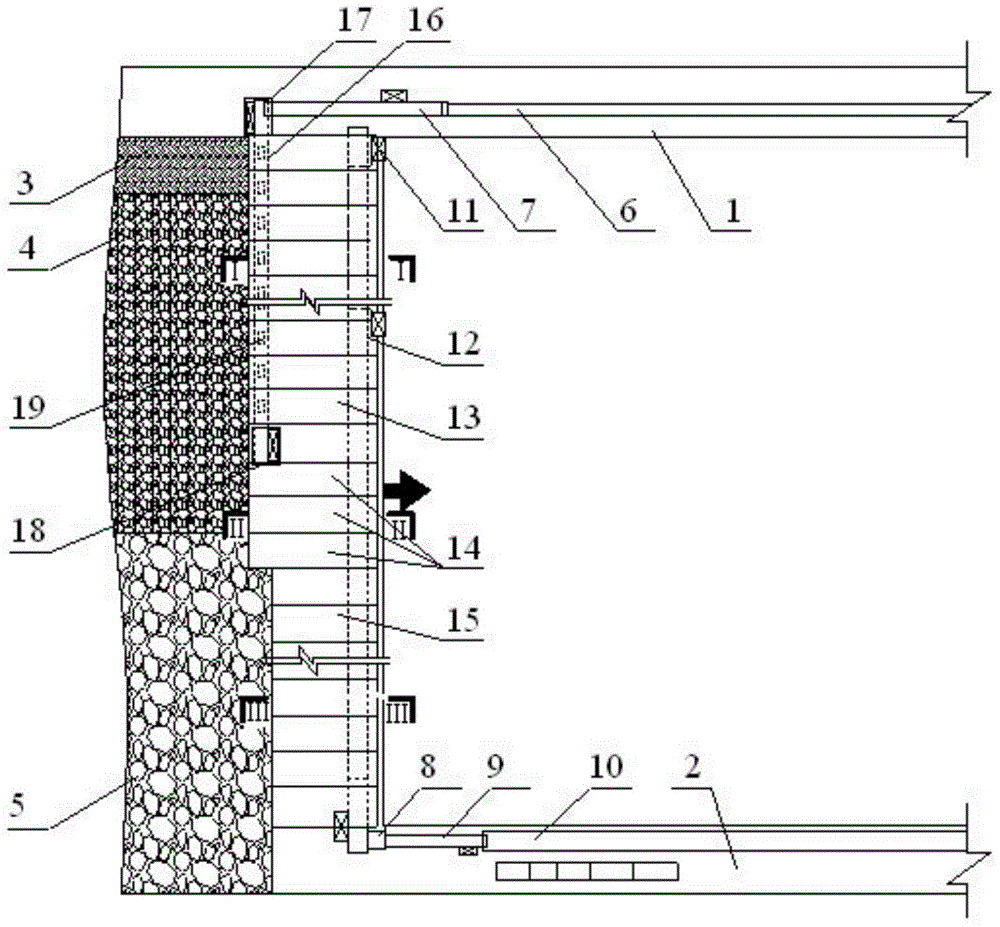

[0020] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

[0021] The solid filling and fully mechanized mining mixed face mining method of the present invention: the specific steps are as follows:

[0022] a. Firstly excavate the section gangue roadway and section coal transportation roadway in the mixed working face of solid filling and fully mechanized mining according to the layout of the fully mechanized mining roadway; To determine the length of the solid filling section and the non-filling section of the fully mechanized mining face, the length of the solid filling section is required to be less than 150m;

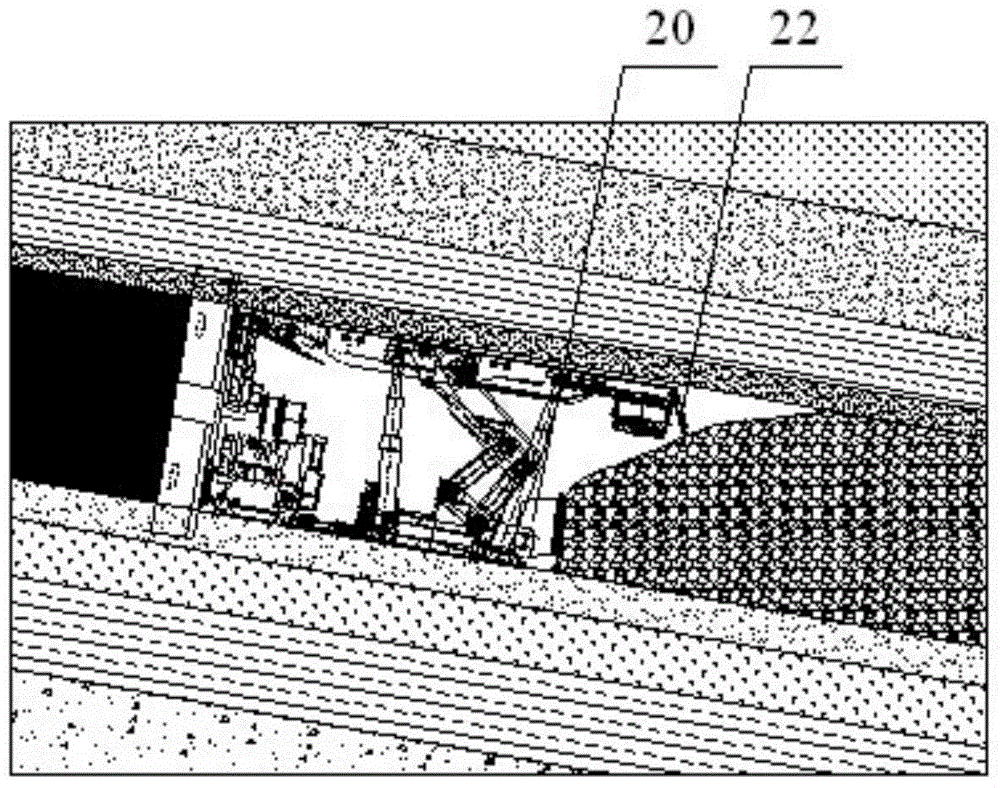

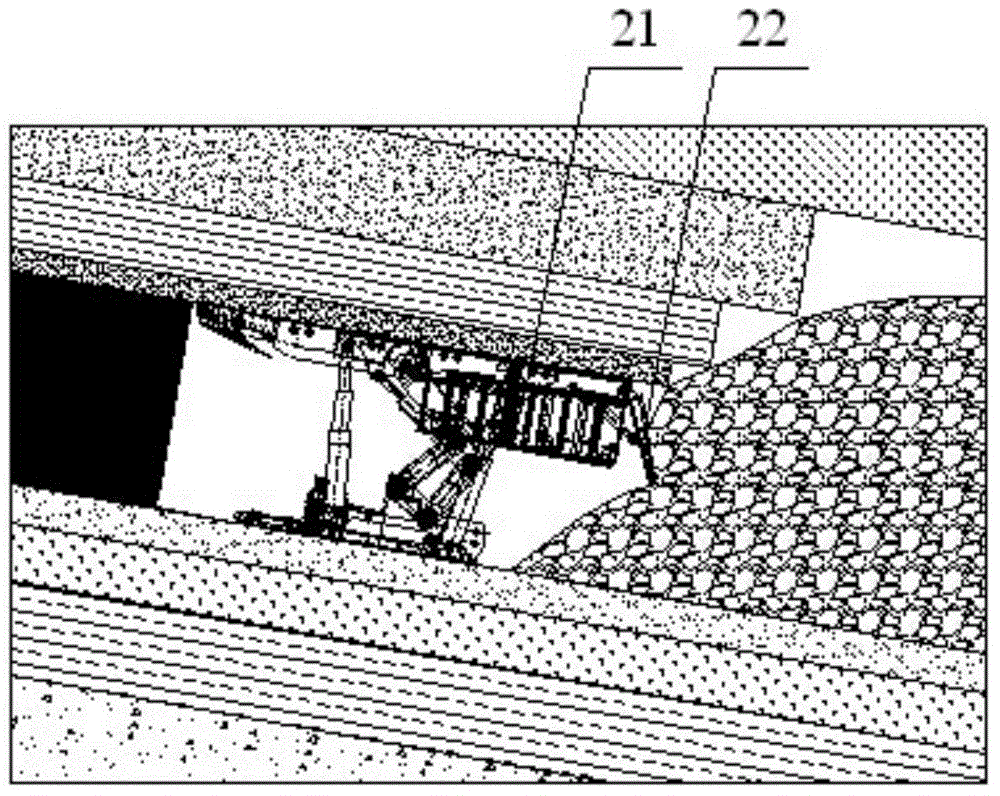

[0023] b. After the excavation of the mining roadway is completed, the shearer 11, the scraper conveyor 12, the filling coal mining hydraulic support 13, the transition hydraulic support 14, the fully mechanized mining hydraulic support 15, and the porous bottom unloading conveyor 16 are arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com