Vanadium pentoxide extraction method by direct acid dipping of stone coal ash containing vanadium

A technology of vanadium pentoxide and coal ash, which is applied in the direction of vanadium oxide, etc., can solve the problems of unsatisfactory overall benefits, affecting extraction operations, and high acid consumption, so as to improve comprehensive utilization benefits, good operating environment, and labor productivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

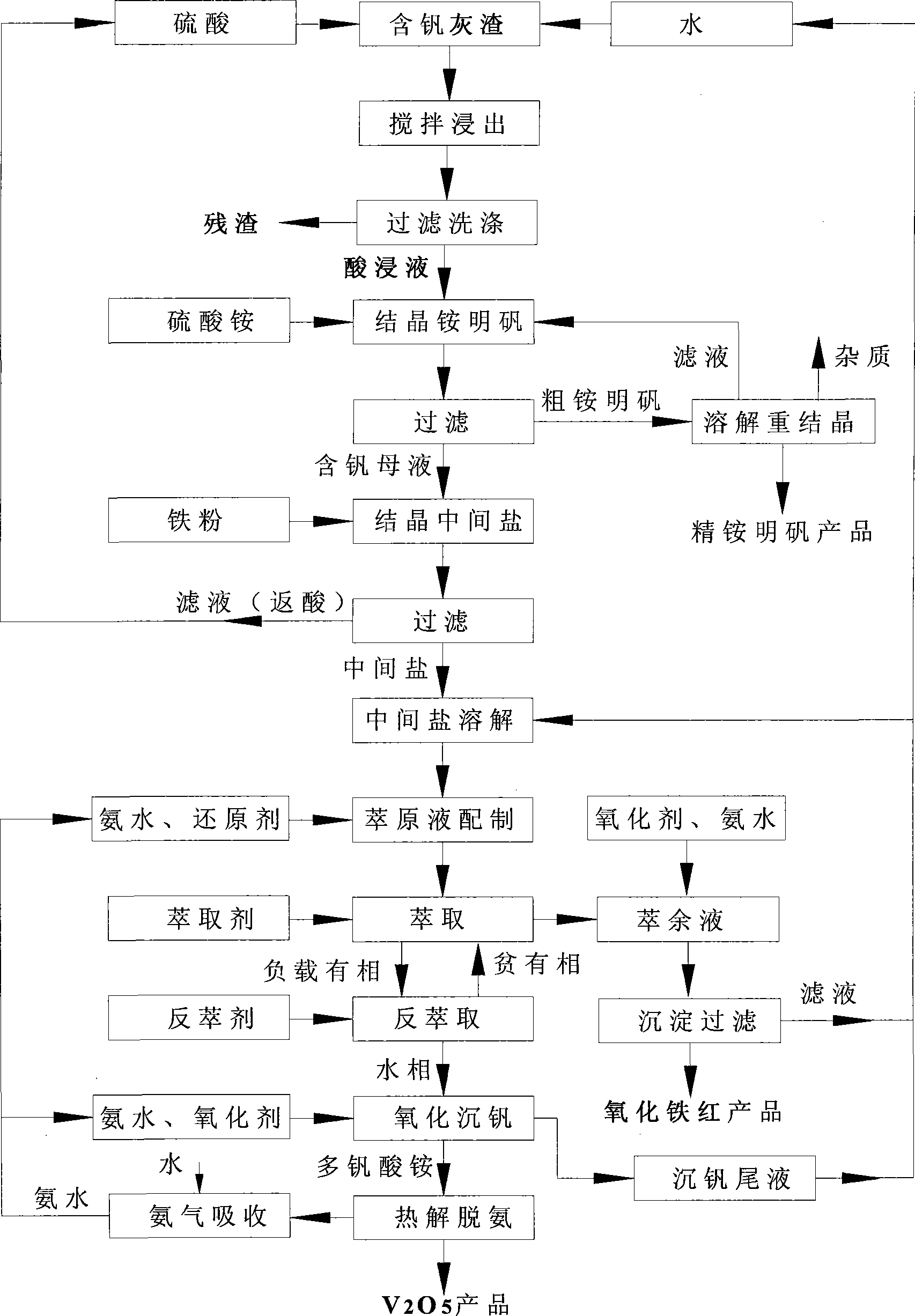

Image

Examples

Embodiment 1

[0055] Institute of Thermal Engineering, Zhejiang University, direct acid leaching extraction of coal ash slag by intermediate salt method V 2 o 5Pilot plant (including acid leaching glass-lined reaction kettle, ammonium alum production glass-lined reaction kettle, intermediate salt evaporation glass-lined reaction kettle, intermediate salt dissolution glass-lined reaction kettle, raw liquid extraction glass-lined reaction kettle, plexiglass tower extraction device, plexiglass tower stripping device, vanadium oxidation precipitation glass-lined reaction kettle and ammonium polyvanadate electric pyrolysis furnace), the treatment capacity of vanadium-containing ash and slag is 800kg / d, and the ash and slag used is discharged from the circulating fluidized bed combustion Bottom slag and dedusting ash, according to the mass ratio, the bottom slag is 25%, and the dedusting ash is 75%. After mixing, it will be used as ash and slag raw materials. Its chemical composition is: V 2 o ...

Embodiment 2

[0076] The vanadium-containing stone coal ash used is the bottom slag and dust removal ash discharged after circulating fluidized bed combustion. The bottom slag is 25% and the dust removal ash is 75% according to the mass ratio. After mixing, it is used as ash raw material. Its chemical composition is: V 2 o 5 1.26%, SiO 2 61.83%, Fe 2 o 3 6.90%, Al 2 o 3 16.58%, CaO 0.30%, MgO 1.31%. The analysis of the occurrence state of vanadium in the ash shows that most of the vanadium occurs in the mica ore, which is a hard-to-leach ore.

[0077] Vanadium pentoxide extraction steps are as follows:

[0078] (1) Acid leaching: Add 1590L of 5mol / L sulfuric acid solution and 533kg of vanadium-containing coal ash to an acid leaching glass-lined reactor, heat to 110-115°C for 4 hours, filter and wash, and take the filtrate to obtain acid leaching liquid, the residue contains V on a dry basis 2 o 5 0.26% (w / w); the residue can be transported to the slag yard for comprehensive utiliza...

Embodiment 3

[0089] The vanadium-containing stone coal ash used is the bottom slag and dust removal ash discharged after circulating fluidized bed combustion. The bottom slag is 25% and the dust removal ash is 75% according to the mass ratio. After mixing, it is used as ash raw material. Its chemical composition is: V 2 o 5 1.26%, SiO 2 61.83%, Fe 2 o 3 6.90%, Al 2 o 3 16.58%, CaO 0.30%, MgO 1.31%. The analysis of the occurrence state of vanadium in the ash shows that most of the vanadium occurs in the mica ore, which is a hard-to-leach ore.

[0090] Vanadium pentoxide extraction steps are as follows:

[0091] (1) Acid leaching: add 5mol / L sulfuric acid solution 2364L (this sulfuric acid solution is the high acidity filtrate that step 3 in the embodiment 2 obtains and the sulfuric acid that newly adds is mixed to form) in the acid leaching glass-lined reaction kettle and vanadium-containing 788kg of lime ash residue, heated to 110-115°C and soaked for 4 hours, filtered and washed, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com