Thick-thin two-purpose automatic bamboo-curtain braiding machine

A weaving machine, dual-purpose technology, applied in mechanical equipment, sugarcane machining and other directions, can solve the problems of inconvenient process, bamboo curtain production, loose handling, and twisted bamboo strips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

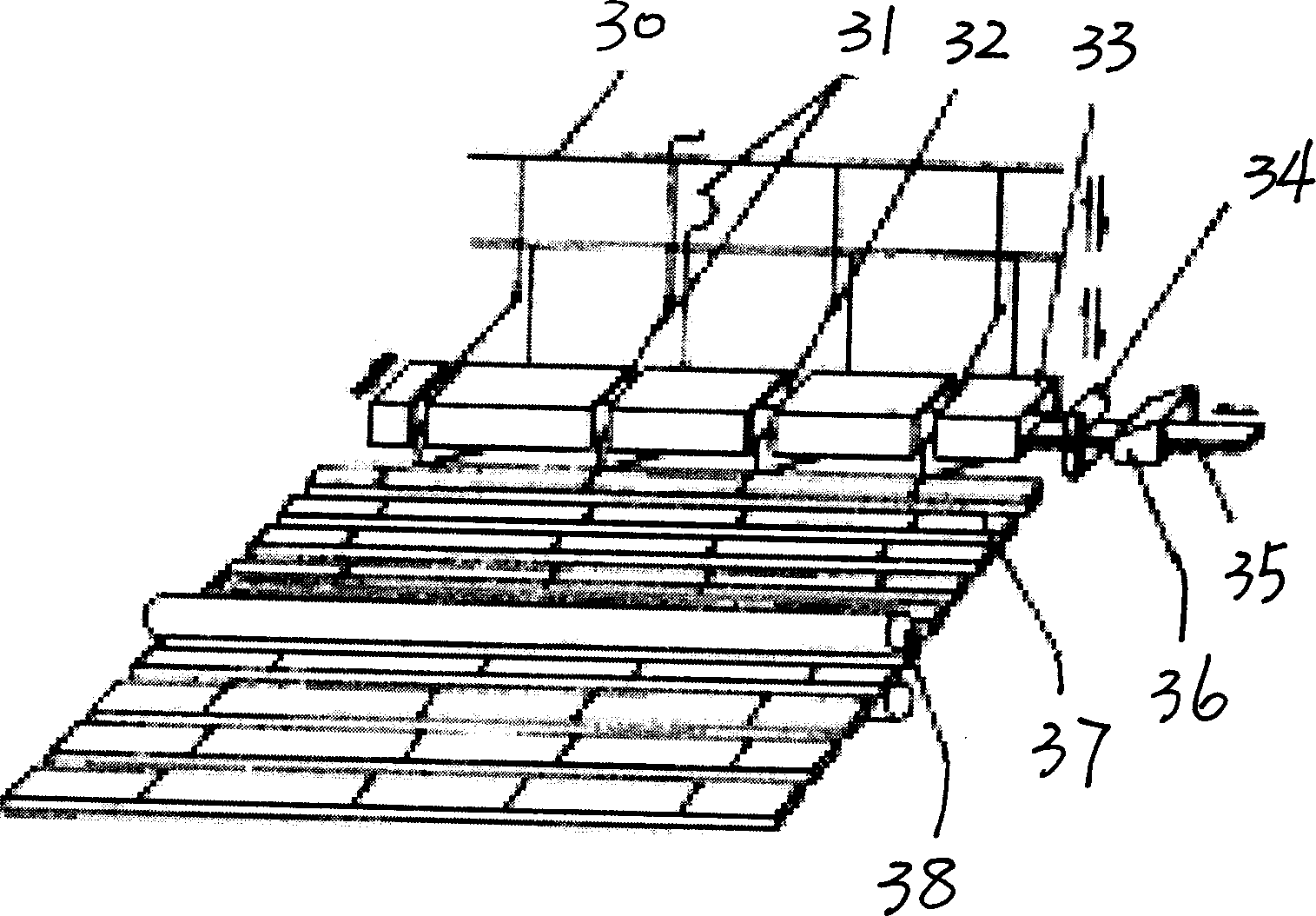

[0017] figure 1 The sequence number in represents: braided wire swing frame 30, braided wire 31, gap 32, feed chute 33, feed roller 34, bamboo raft 35, guide opening 36, bamboo curtain 37, hold down stick 38.

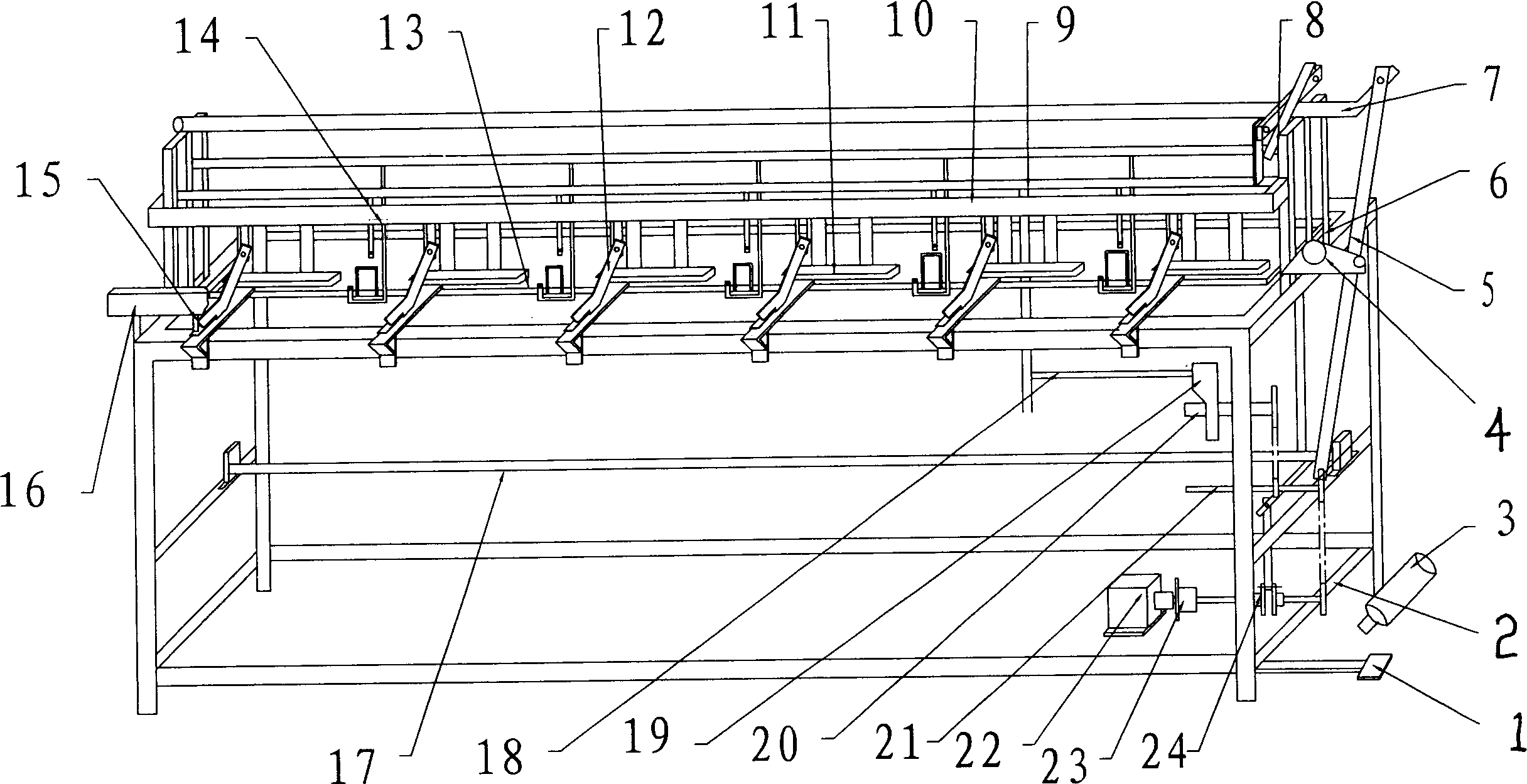

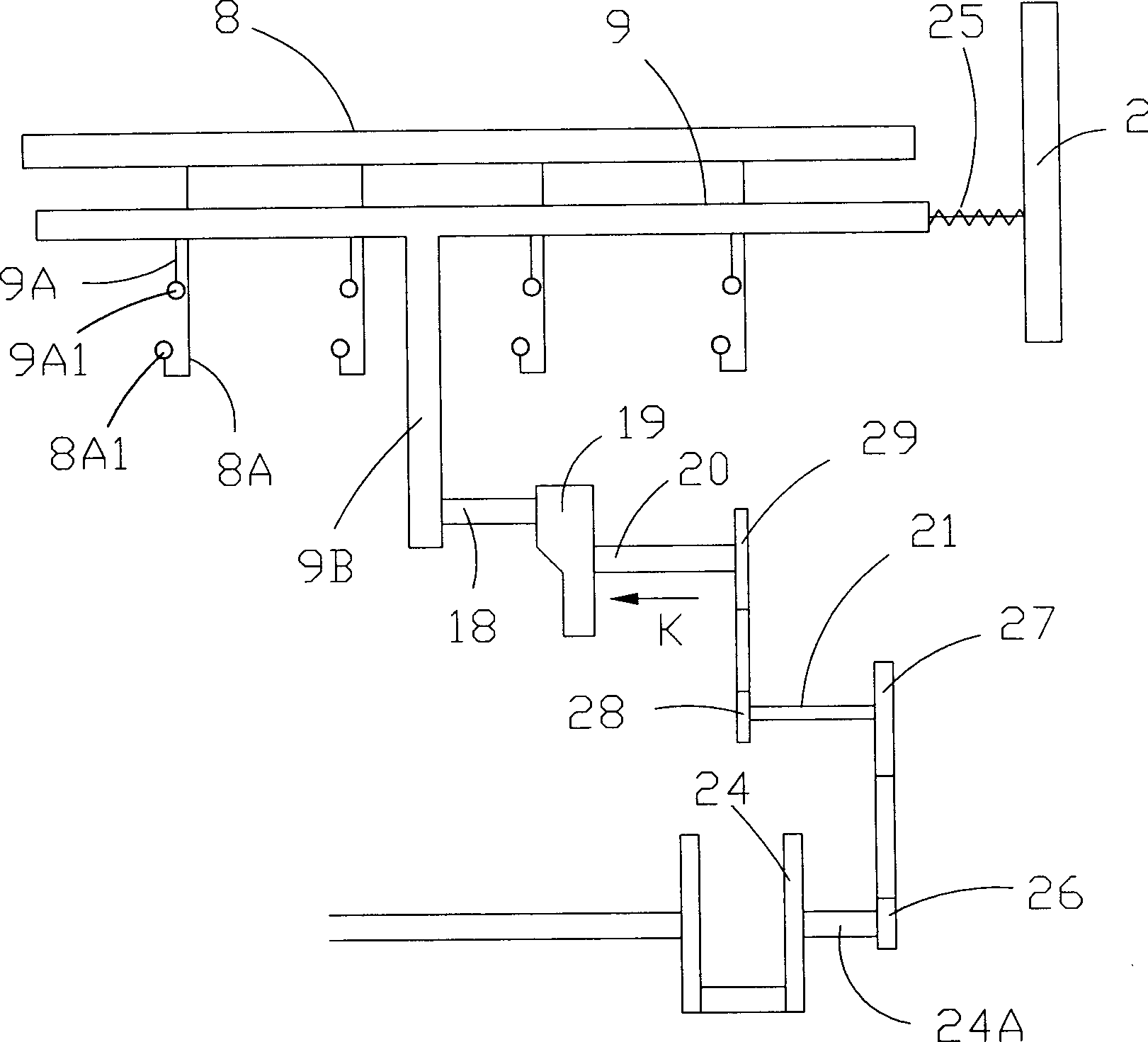

[0018] Figure 2 to Figure 4 The serial numbers in it represent respectively: clutch pedal 1, frame 2, motor 3, bamboo feeding structure 4, upper and lower thread change ejector rod 5, pulley 6, upper and lower thread change connecting rod 7, rear threading rod 8, rear lead needle 8A, Rear threading needle hole 8A1, front threading rod 9, front threading needle 9A, front threading needle hole 9A1, left and right thread change connecting rod 9B, bamboo box beam 1 0, bamboo box 11, bamboo guide stopper 12, pushing bamboo frame 13 , thread tensioning frame 14, raft compactor 1 5, raft compactor beam 16, swing lever 17, left and right thread changing jack 18, cam 19, camshaft 20, bridge shaft 21, reducer 22, clutch 23 , crankshaft device 24, crankshaft one end 24A, return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com