An oil-filled communication cable longitudinal wrapping processing system and processing technology

A communication cable and processing system technology, applied in cable/conductor manufacturing, conductor/cable supply devices, circuits, etc., can solve the problem of high cost of wrapping and tape equipment and raw materials, inability to meet the needs of oil-filled communication cables, winding The problems of low production efficiency of packaging tapes can reduce the use of packaging tapes, avoid poor welding quality, and improve reliability and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

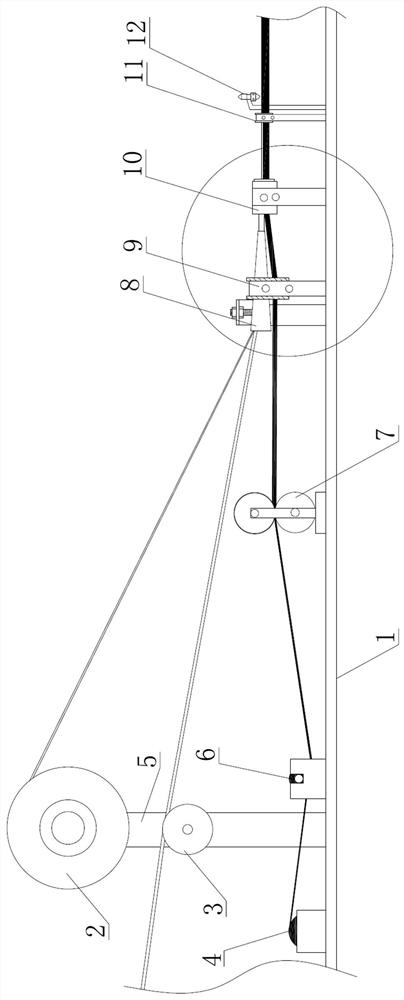

[0035] like figure 1 As shown, the invention discloses an oil-filled communication cable longitudinal wrapping processing system and processing technology.

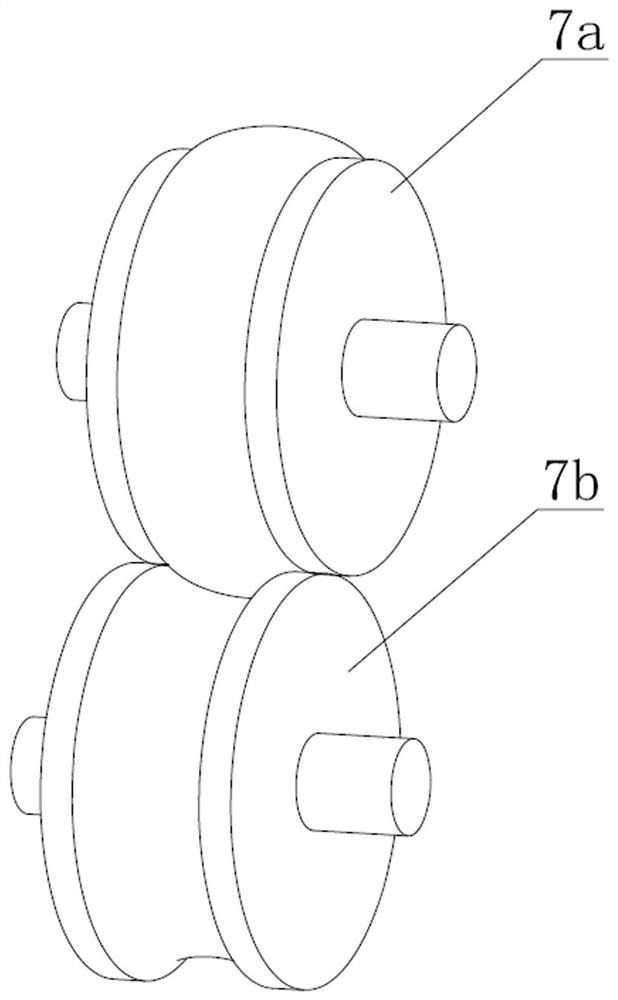

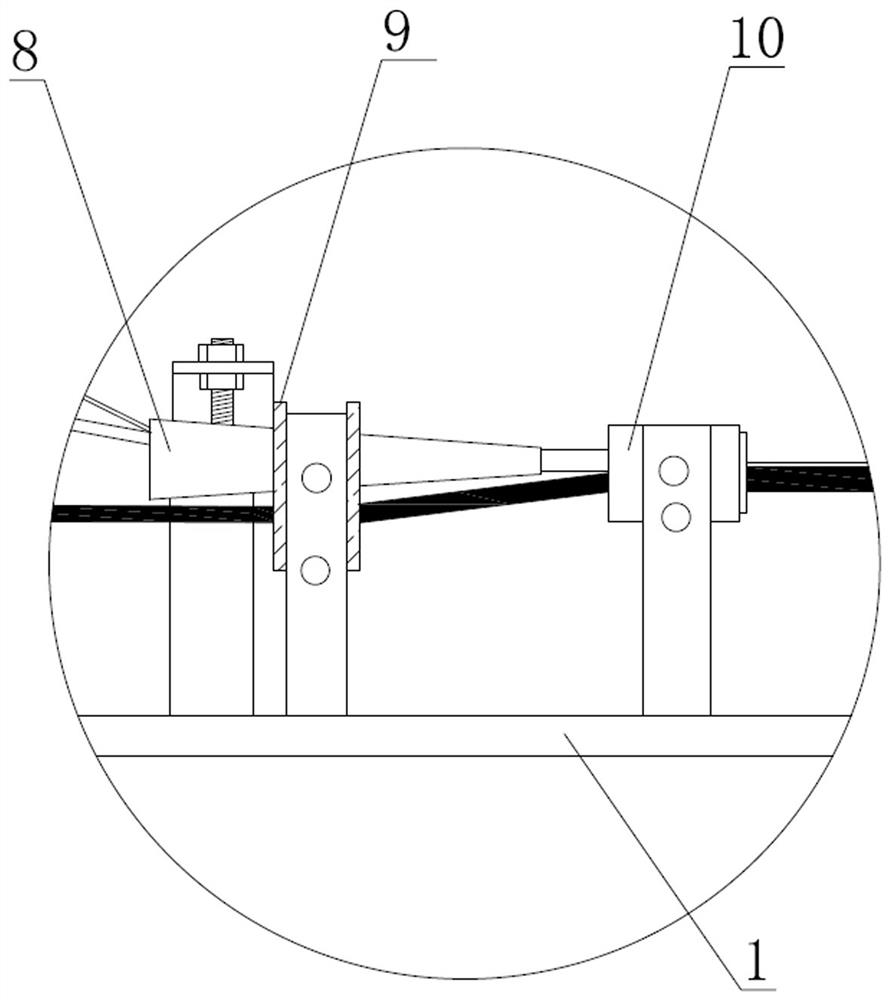

[0036] The oil-filled communication cable longitudinal wrapping processing system includes a support platform 1, on which an inner sheath processing mechanism and an outer sheath processing mechanism are arranged on the left and right, the cable core passes through the inner sheath processing mechanism and the outer sheath processing mechanism in turn, and the inner sheath processing mechanism Between the layer processing mechanism and the outer sheath processing mechanism, there are aluminum sheath conveying mechanism, tape conveying mechanism, cable core conveying mechanism and tape sheath processing mechanism, aluminum sheath conveying mechanism, tape conveying mechanism and cable core conveying mechanism The mechanisms are located on the left side of the tape sheath processing mechanism;

[0037] Tape sheath processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com