Method for preparing tundish seating brick ramming material by using waste magnesia slag wall

A slag retaining wall and ramming material technology, applied in the field of refractory materials, can solve the problems of unsecured safety factors, waste of refractory raw material resources, inconsistent resource conservation, etc., to prevent particle segregation, save refractory resources, The effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

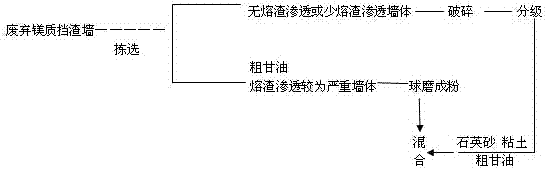

[0032] A method for preparing tundish seat brick ramming material by using waste magnesia slag retaining wall:

[0033] Classify the recycled waste magnesia slag retaining wall: knock out the wall blocks with more severe slag penetration (that is, the metamorphic layer is thicker and located at the slag line). After the removal, the surface residues are manually removed: Use a hammer to remove the remaining surface residues and steel of the slag retaining wall by knocking. After the surface residue is manually removed, it is sent to the crusher receiving hopper. After the crusher, the particles are sieved into 5-3, 3-1, and 1-0mm particles according to the batching requirements of refractory materials. The wall blocks of metamorphic layer with severe slag penetration are ball milled into 200 mesh powder.

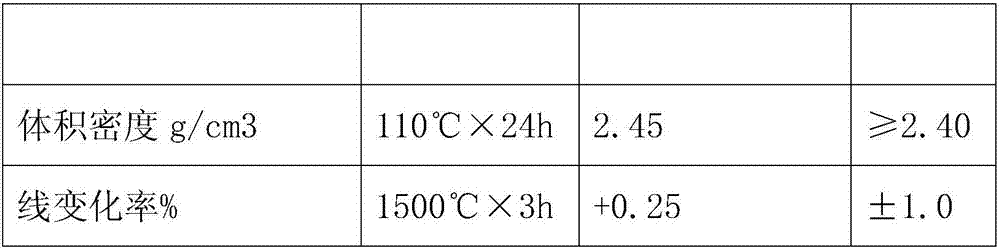

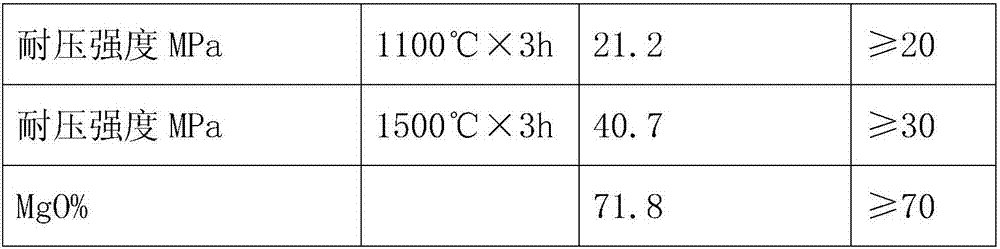

[0034] According to the following composition ratio: waste: 5-3mm 20%; 3-1mm 25%; 1-0mm 15%; 90 magnesia 200 mesh 22%; 1-0mm quartz sand 5%; clay 4.5%; six partial 0.5% ; Metam...

Embodiment 2

[0040] A method for preparing tundish seat brick ramming material using waste magnesia slag retaining wall:

[0041] Classify the recycled waste magnesia slag retaining wall: knock out the wall blocks with more severe slag penetration (that is, the metamorphic layer is thicker and located at the slag line). After the removal, the surface residues are manually removed: Use a hammer to remove the remaining surface residues and steel of the slag retaining wall by knocking. After the surface residue is manually removed, it is sent to the crusher receiving hopper. After passing through the crusher, the particles are sieved into 5-3, 3-1, and 1-0mm particles according to the batching requirements of refractory materials. The wall blocks of metamorphic layer with more severe slag penetration are ball milled into 200 mesh powder.

[0042] According to the following composition ratio: waste: 5-3mm 18%; 3-1mm 26%; 1-0mm 16%; 90 magnesia 200 mesh 22%; 1-0mm quartz sand 5%; clay 4.5%; six par...

Embodiment 3

[0048] A method for preparing tundish seat brick ramming material by using waste magnesia slag retaining wall:

[0049] Classify the recycled waste magnesia slag retaining wall: knock out the wall blocks with more severe slag penetration (that is, the metamorphic layer is thicker and located at the slag line). After the removal, the surface residues are manually removed: Use a hammer to remove the remaining surface residues and steel of the slag retaining wall by knocking. After the surface residue is manually removed, it is sent to the crusher receiving hopper. After passing through the crusher, the particles are sieved into 5-3, 3-1, and 1-0mm particles according to the batching requirements of refractory materials. The wall blocks of metamorphic layer with severe slag penetration are ball milled into 200 mesh powder.

[0050] According to the following composition ratio: waste: 5-3mm 19%; 3-1mm 24%; 1-0mm 17%; 90 magnesia 200 mesh 23%; 1-0mm quartz sand 4%; clay 4.5%; six parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com