Multifunctional efficient hamburger machine

A hamburger machine, high-efficiency technology, applied in kitchen utensils, household utensils, roasters/barbecue grills, etc., can solve the problems of workers' health status, poor air quality in the working environment, and increased costs, and achieve the goal of taking food The process is simple, fast and orderly, saving manpower and space, and avoiding the effect of contact with impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

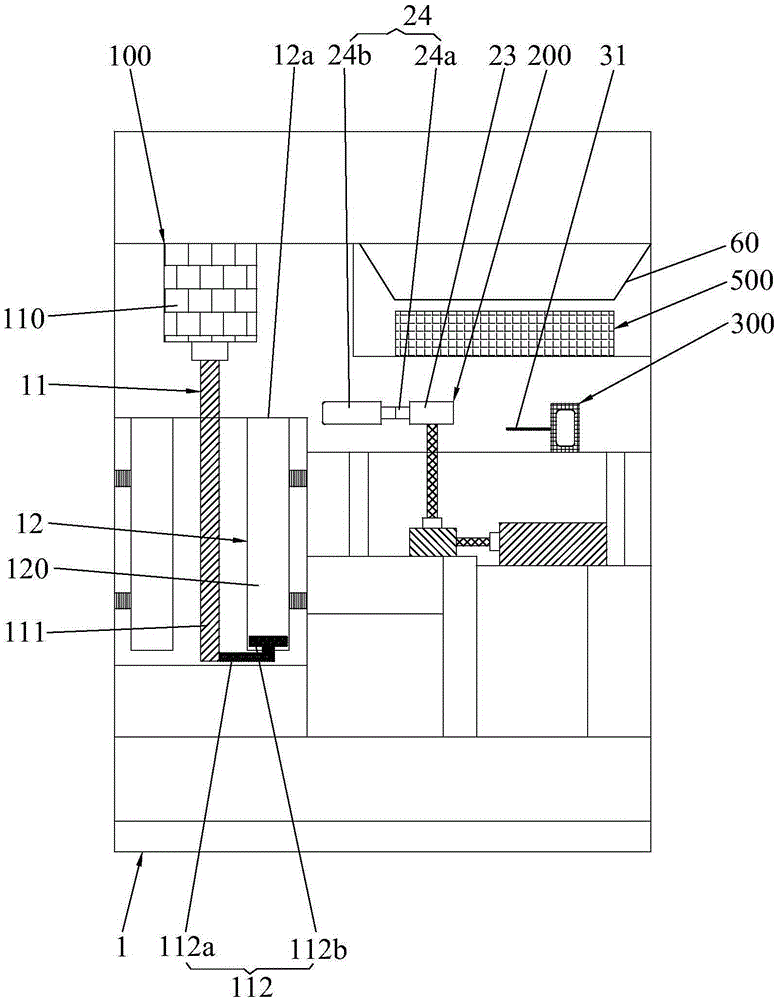

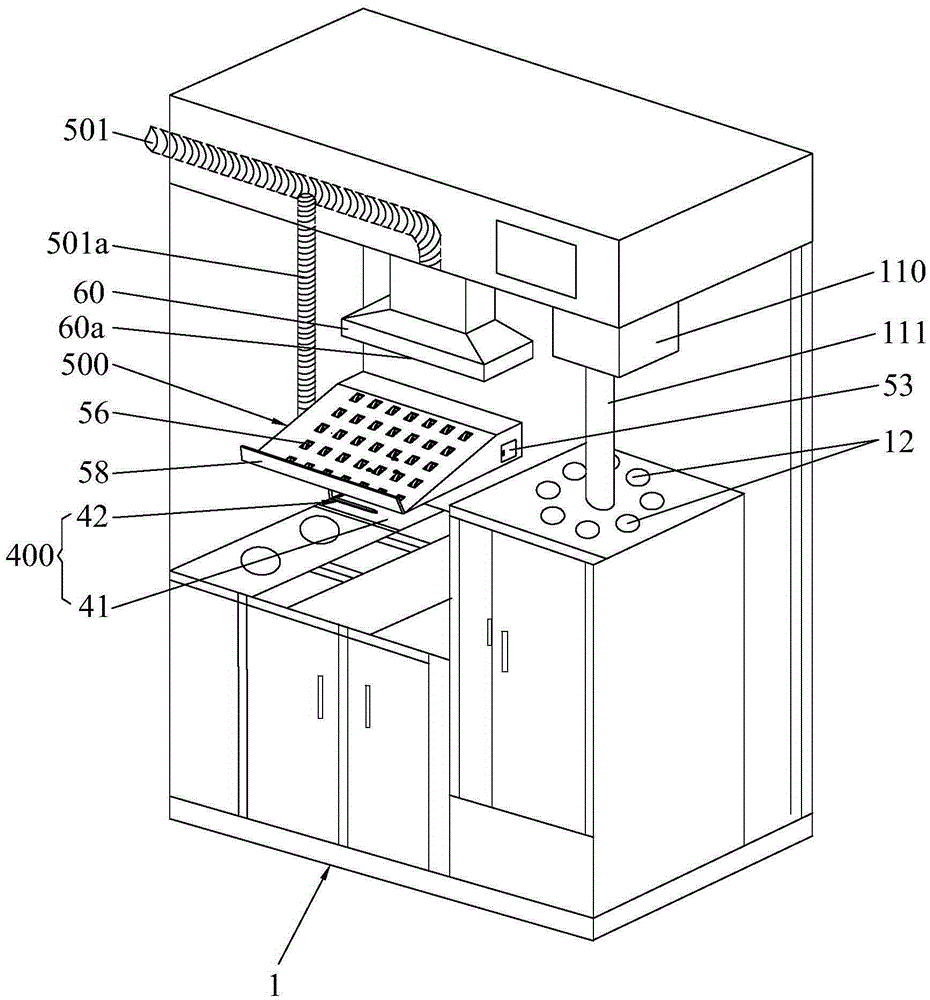

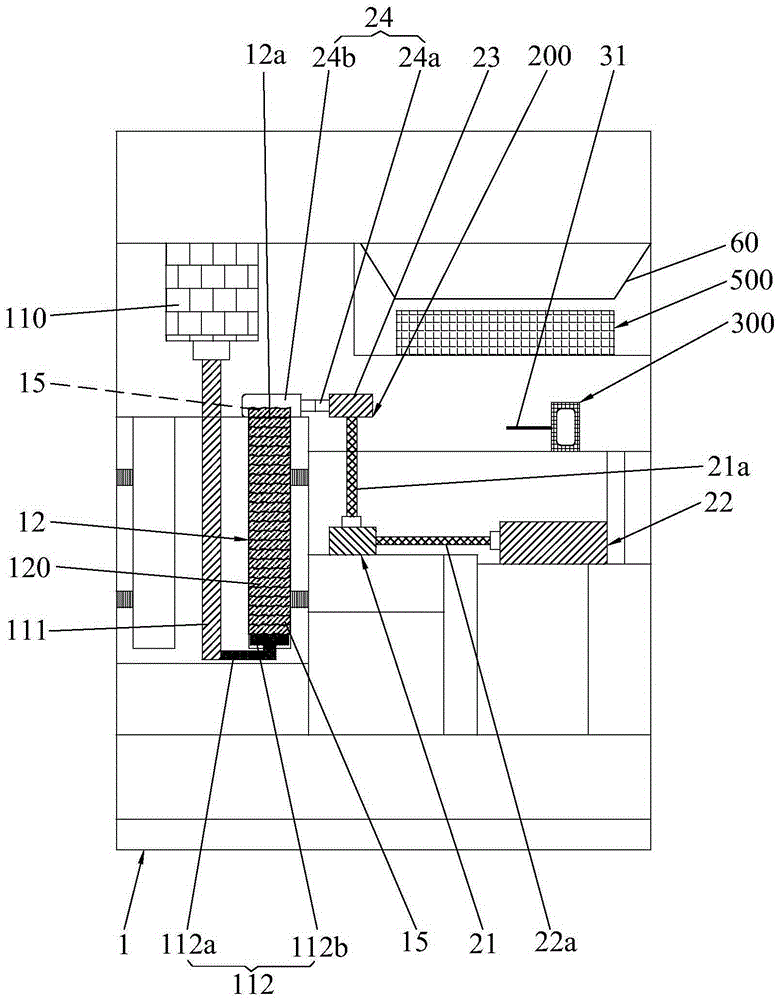

[0049] Such as Figure 1a and Figure 1bAs shown, the multifunctional and high-efficiency hamburger machine of the present invention includes a frame 1 and a food storage mechanism 100 of the hamburger machine arranged on the frame 1, a clamping mechanism 200 of the hamburger machine, an overturning mechanism 300 of the hamburger machine, and a hamburger machine. The frying tank mechanism 400 of the hamburger machine and the range fume mechanism 500 of the hamburger machine, the food storage mechanism of the hamburger machine is used to store and push food, the food storage mechanism 100 of the hamburger machine is arranged on the frame 1, has The storage cylinder 12 for storing food 15, and the drive assembly 11 that pushes the food in the storage cylinder 12 out of the upper opening 12a; the clamping mechanism 200 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com