Patents

Literature

38results about How to "Easy to get up and down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

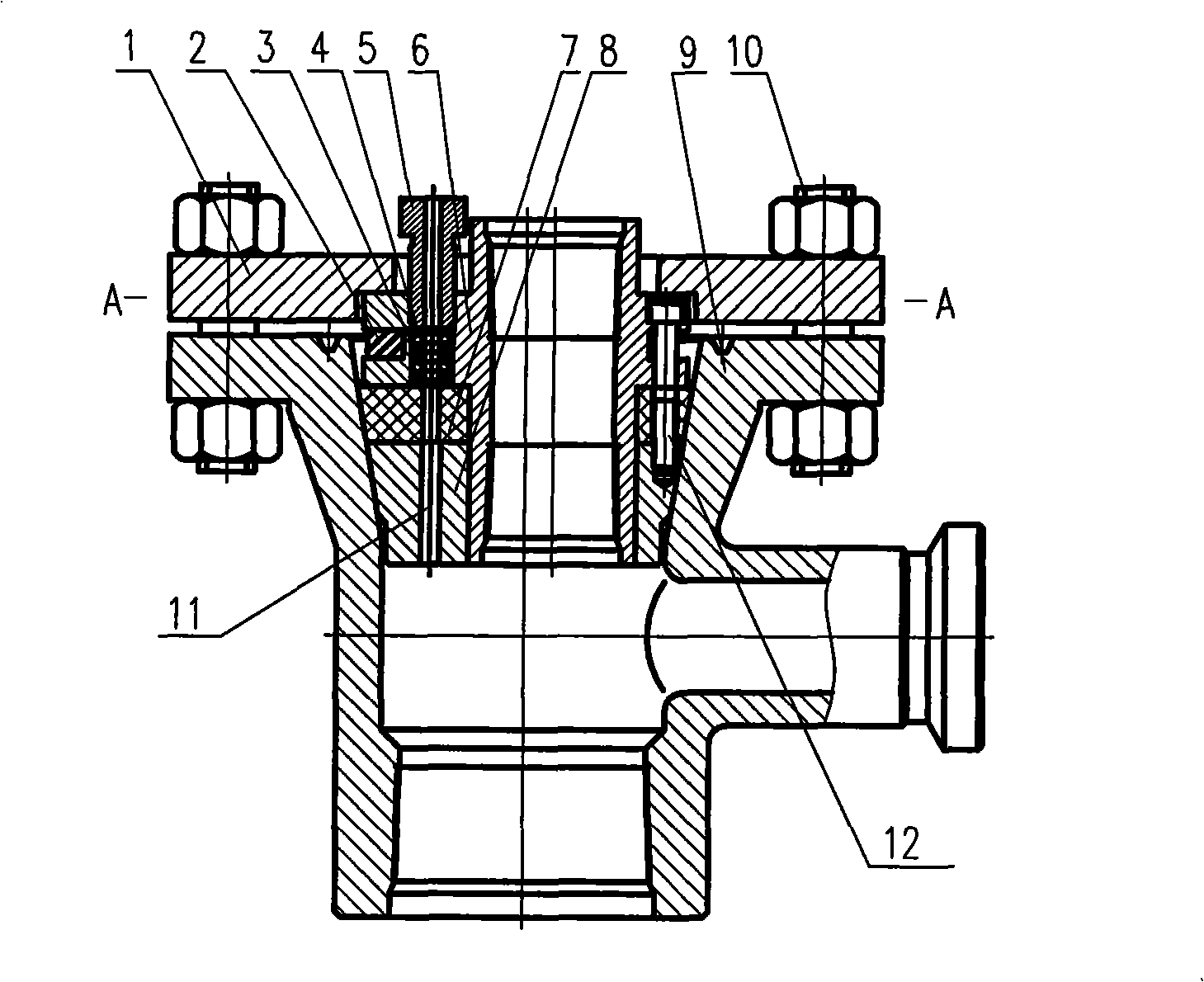

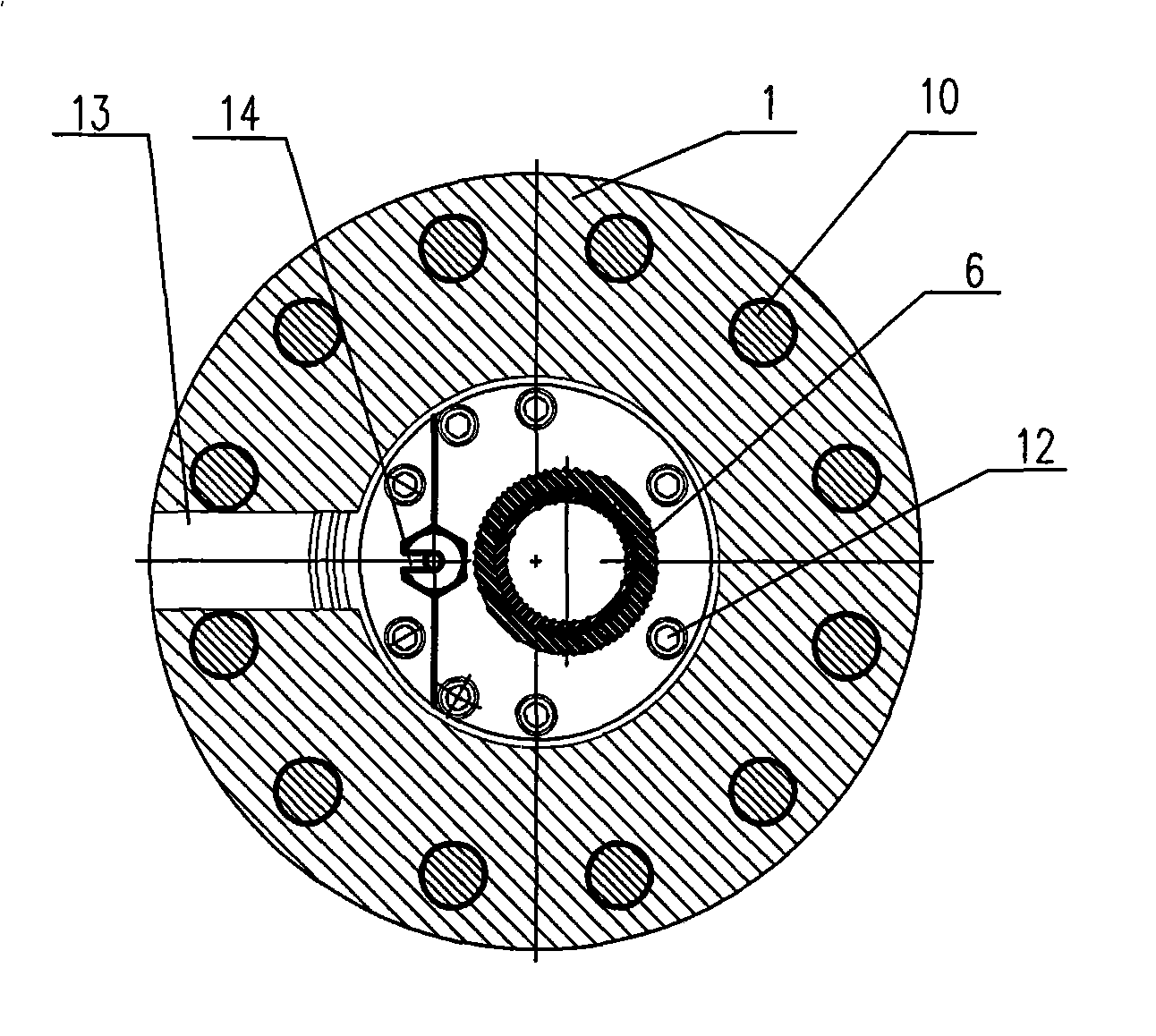

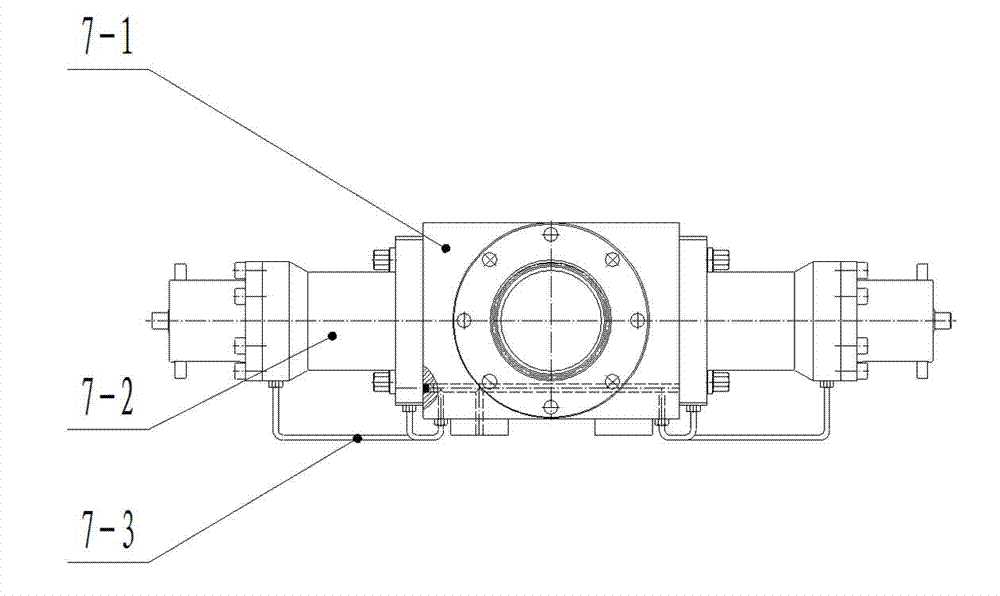

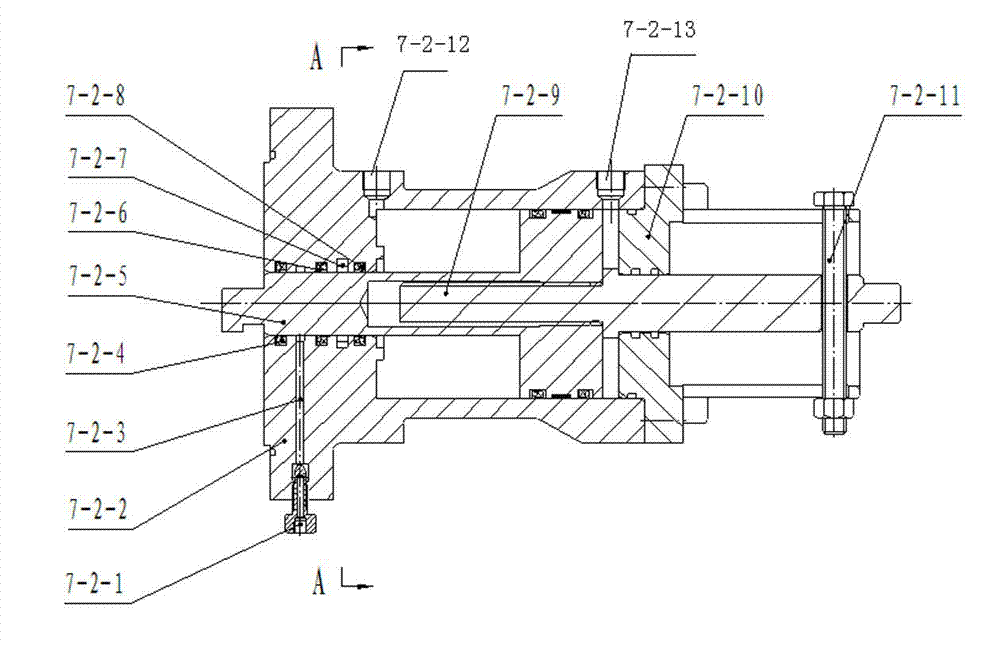

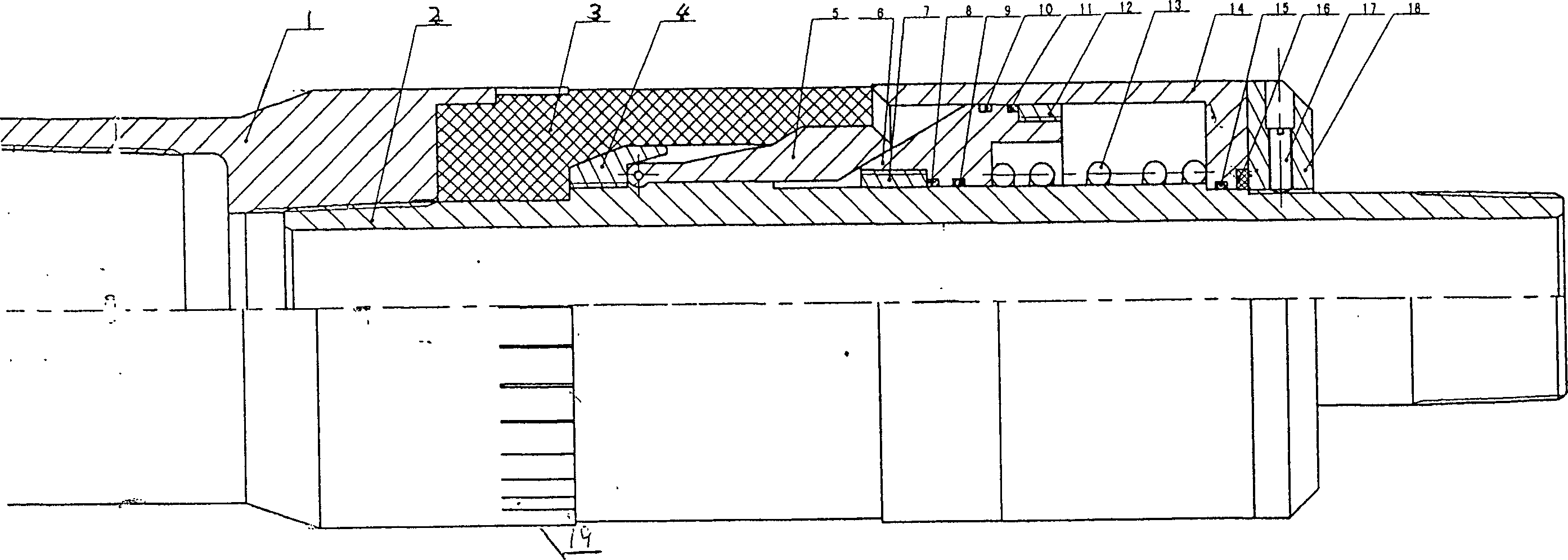

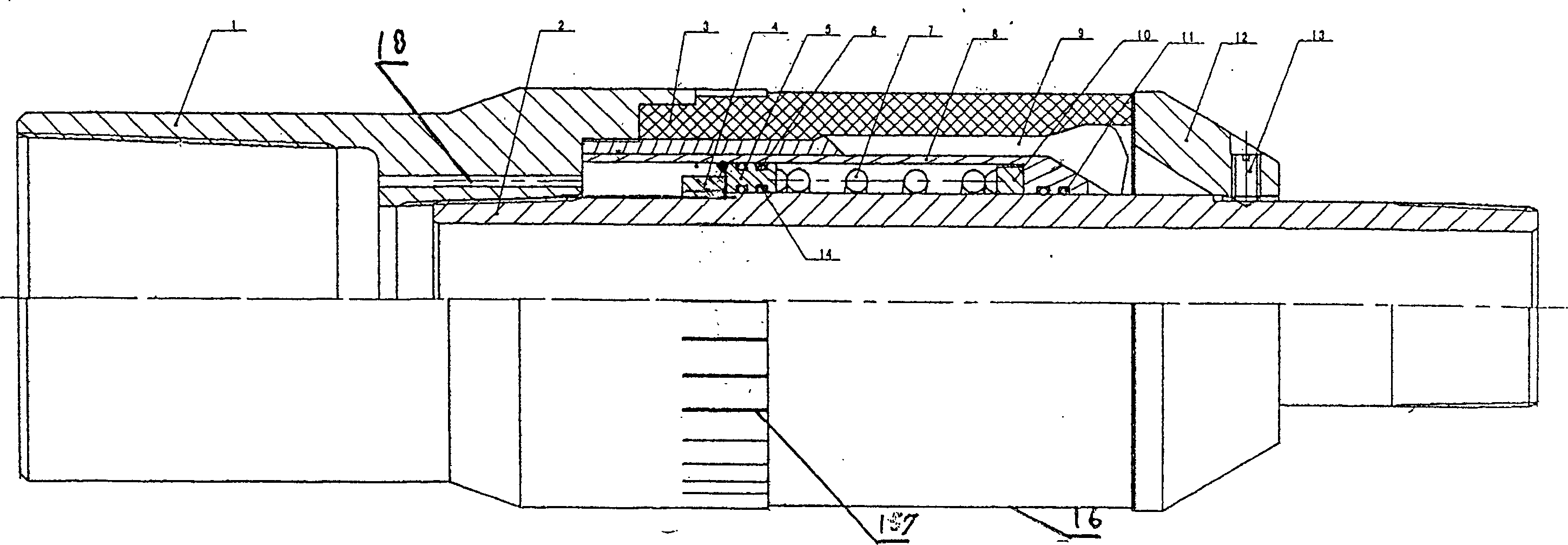

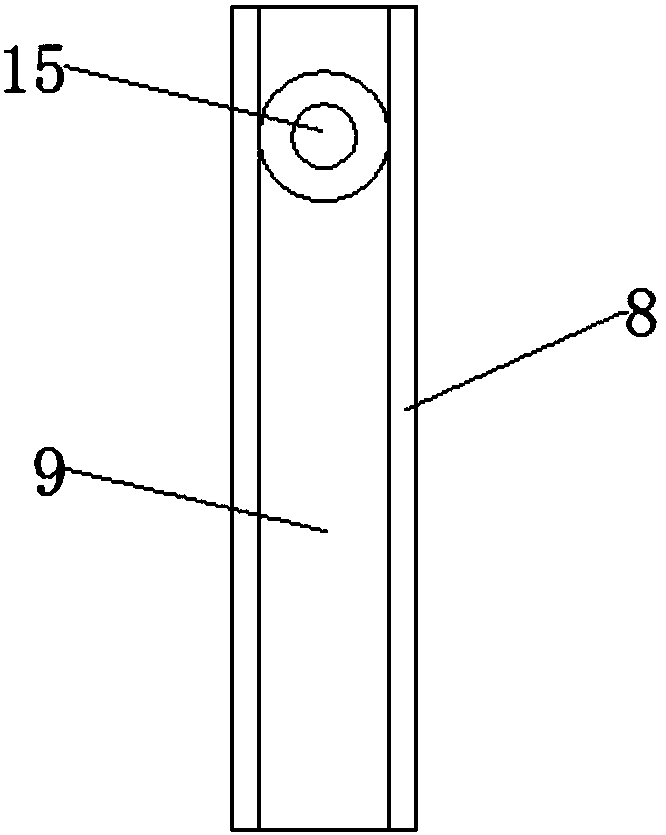

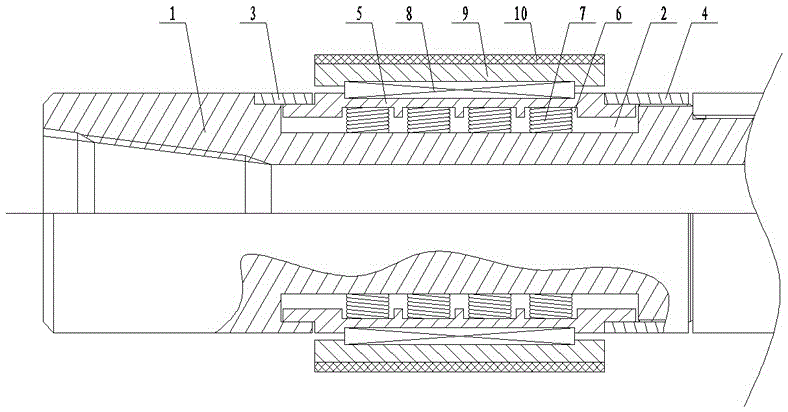

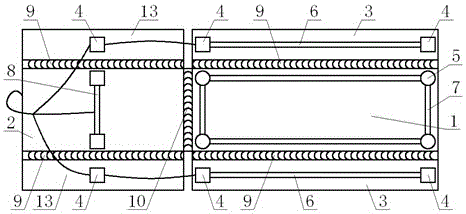

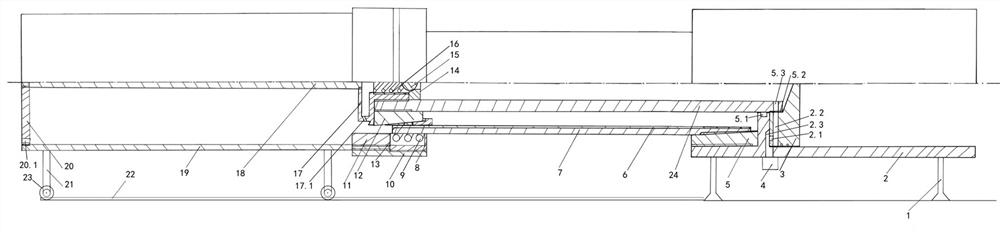

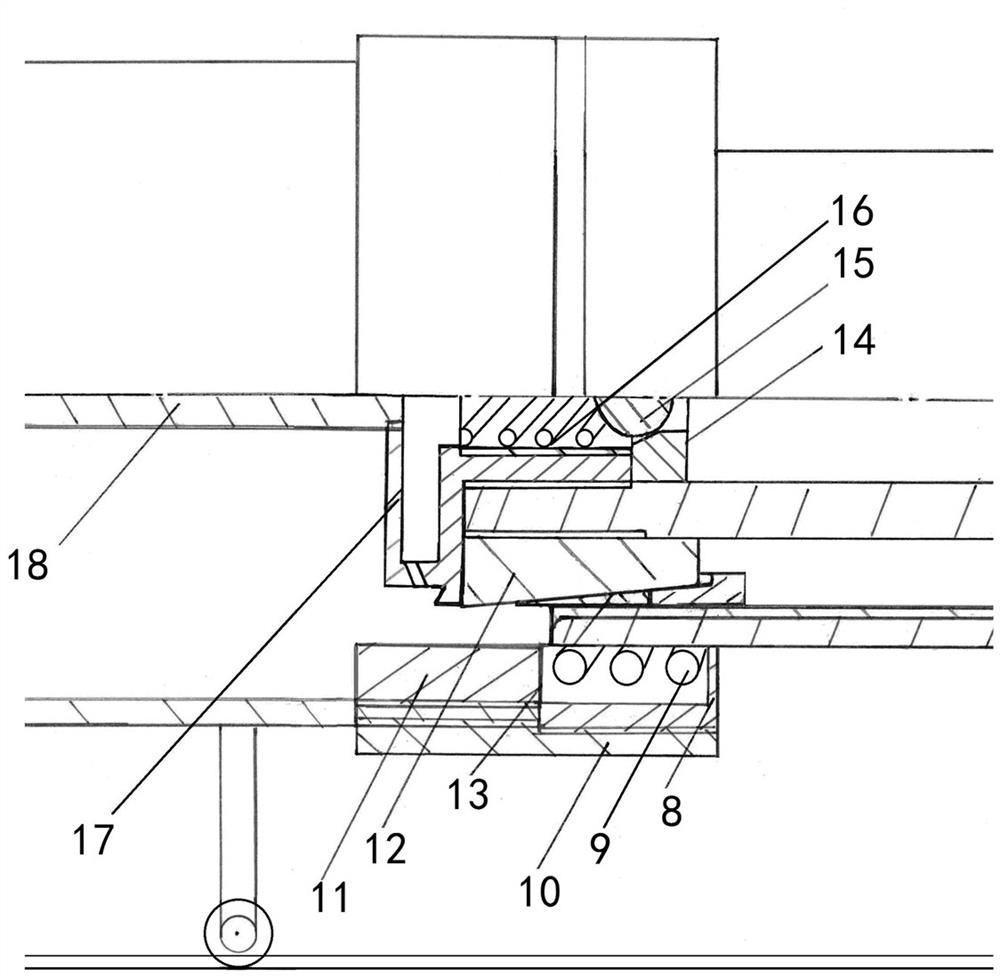

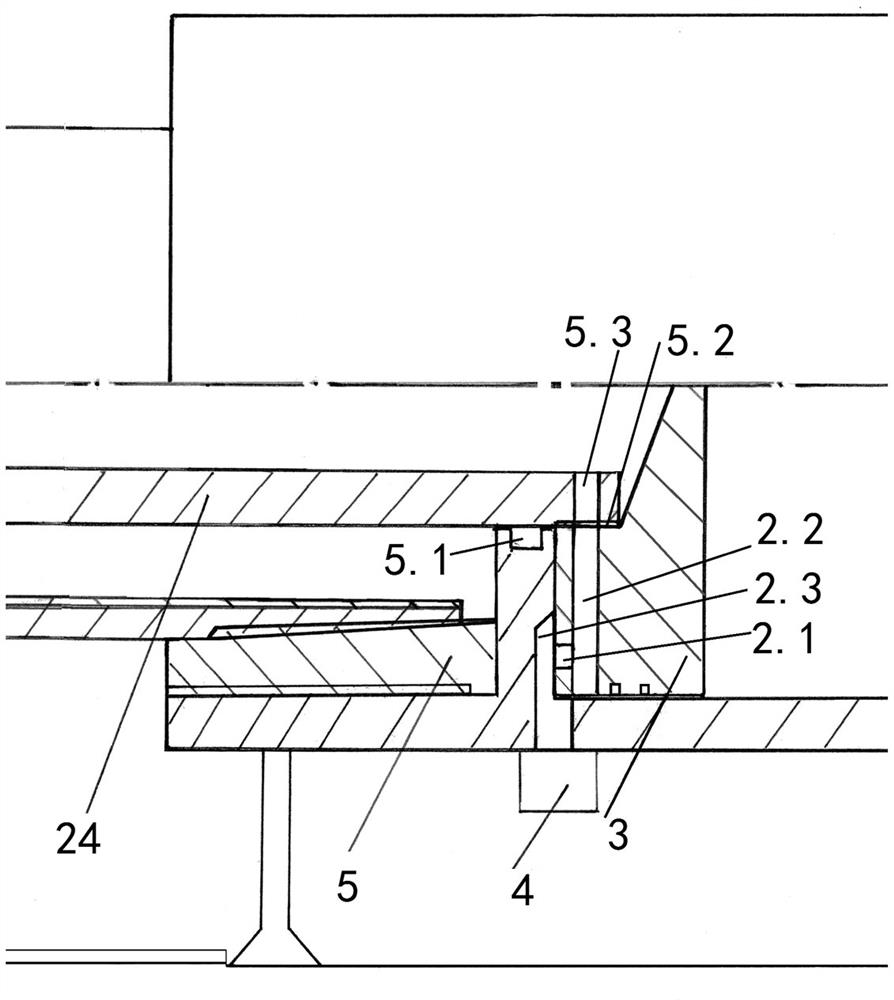

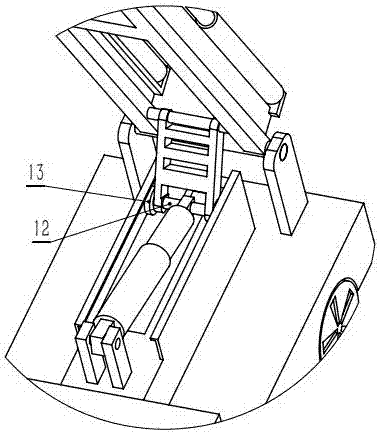

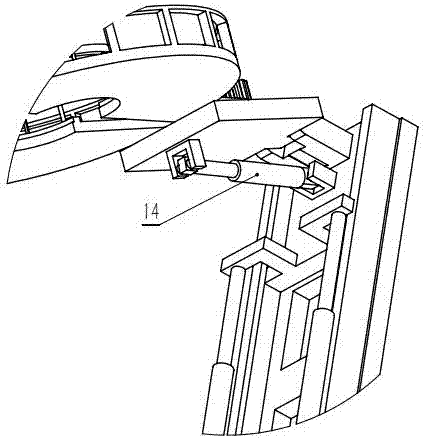

Preset production fluid section plane test method of mechanical mining horizontal well and special shaft mouth test apparatus

ActiveCN101403291AEasy to get up and downSo as not to damageSurveySealing/packingSection planeTubing hanger

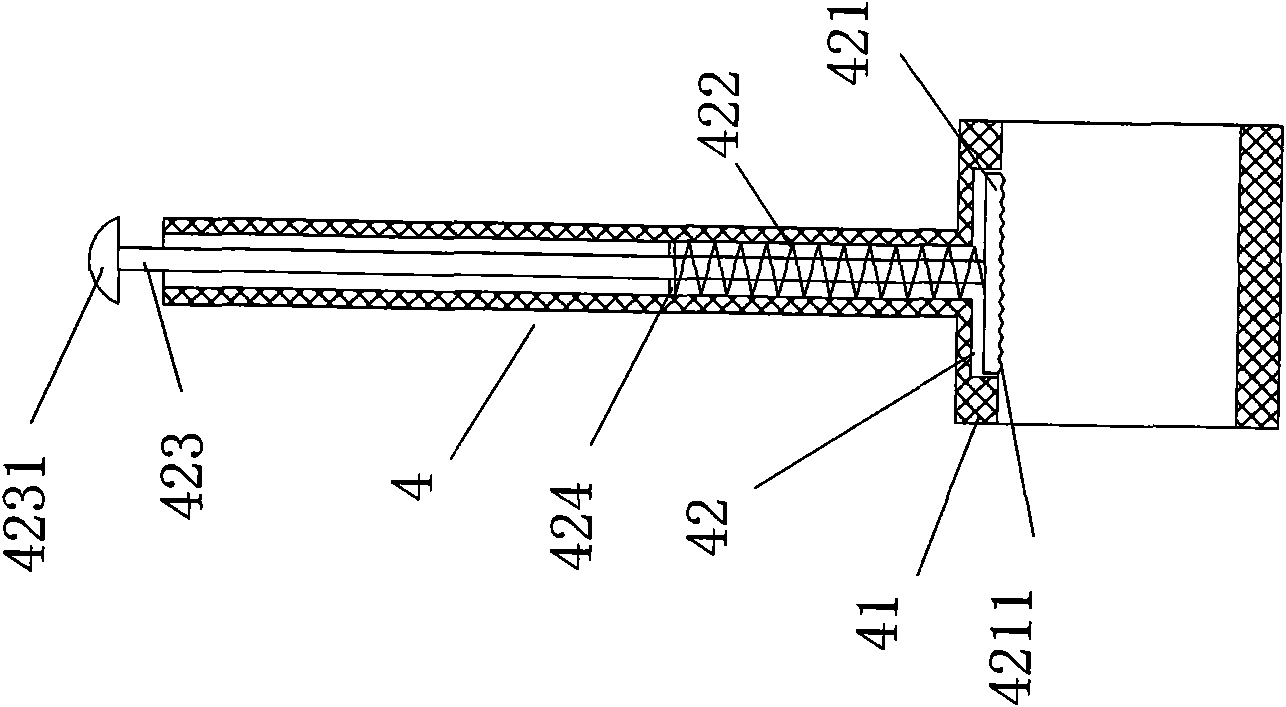

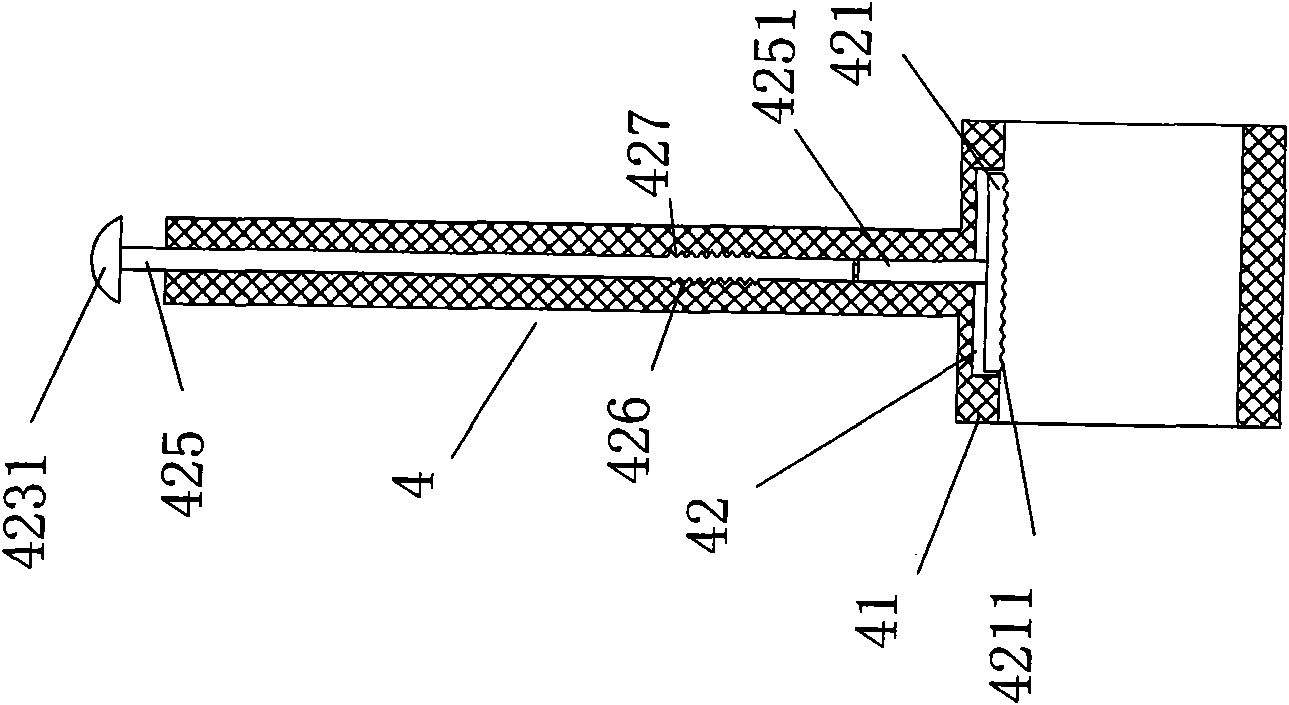

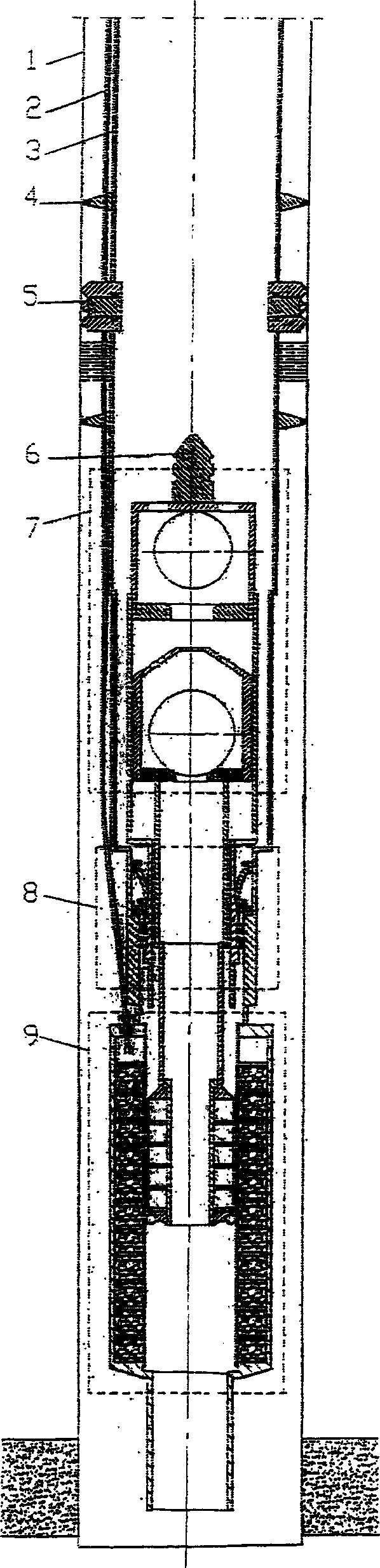

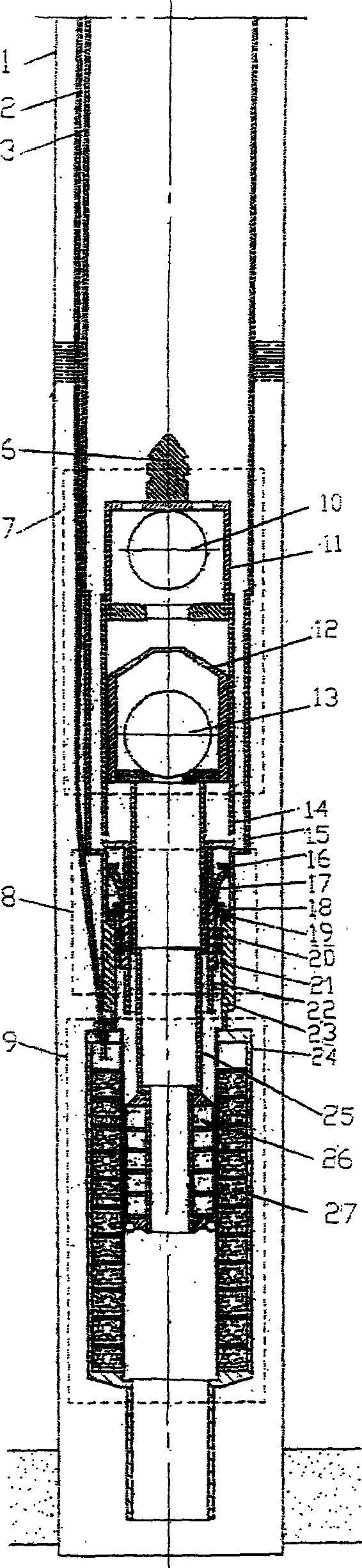

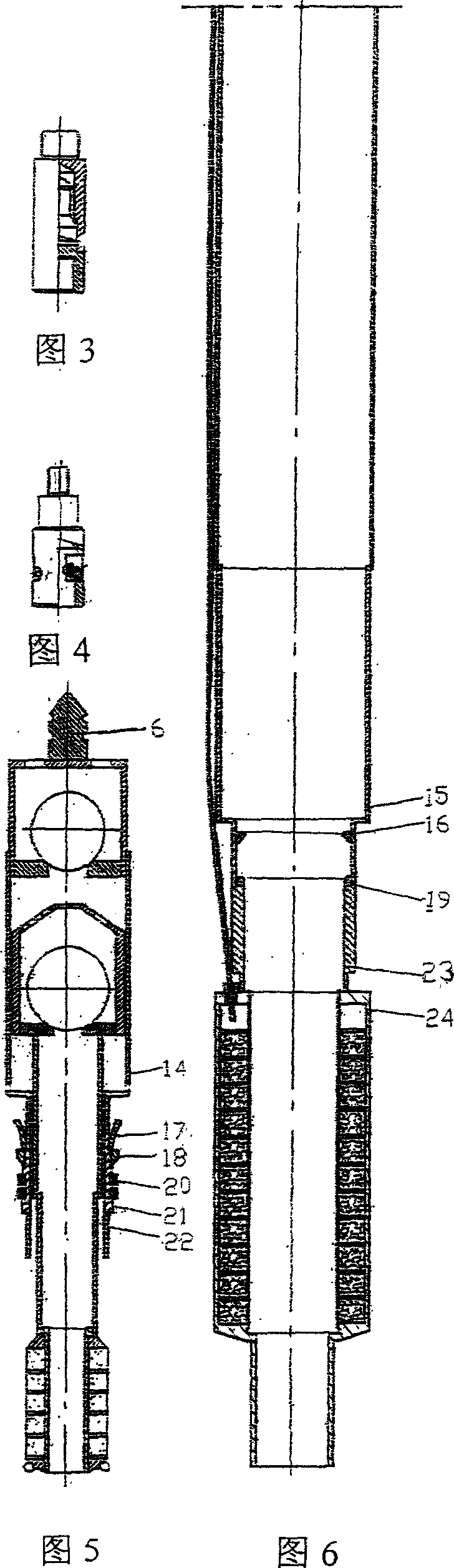

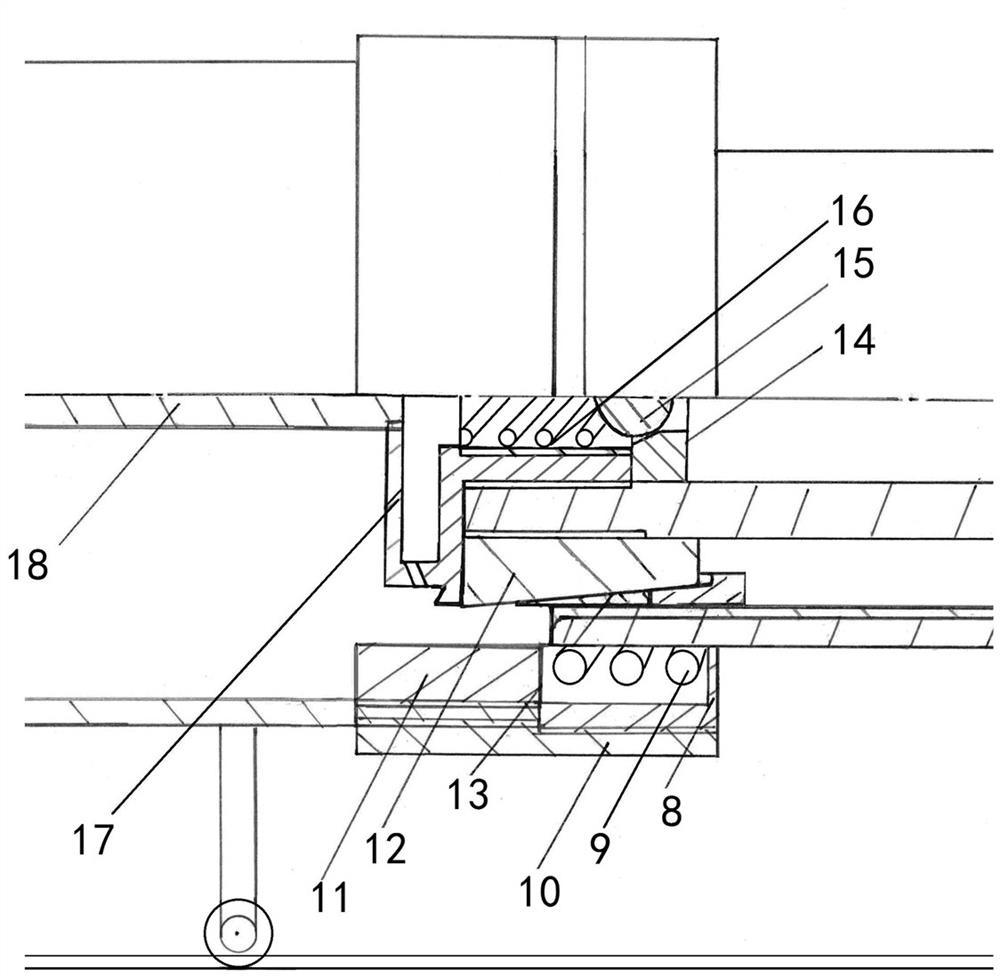

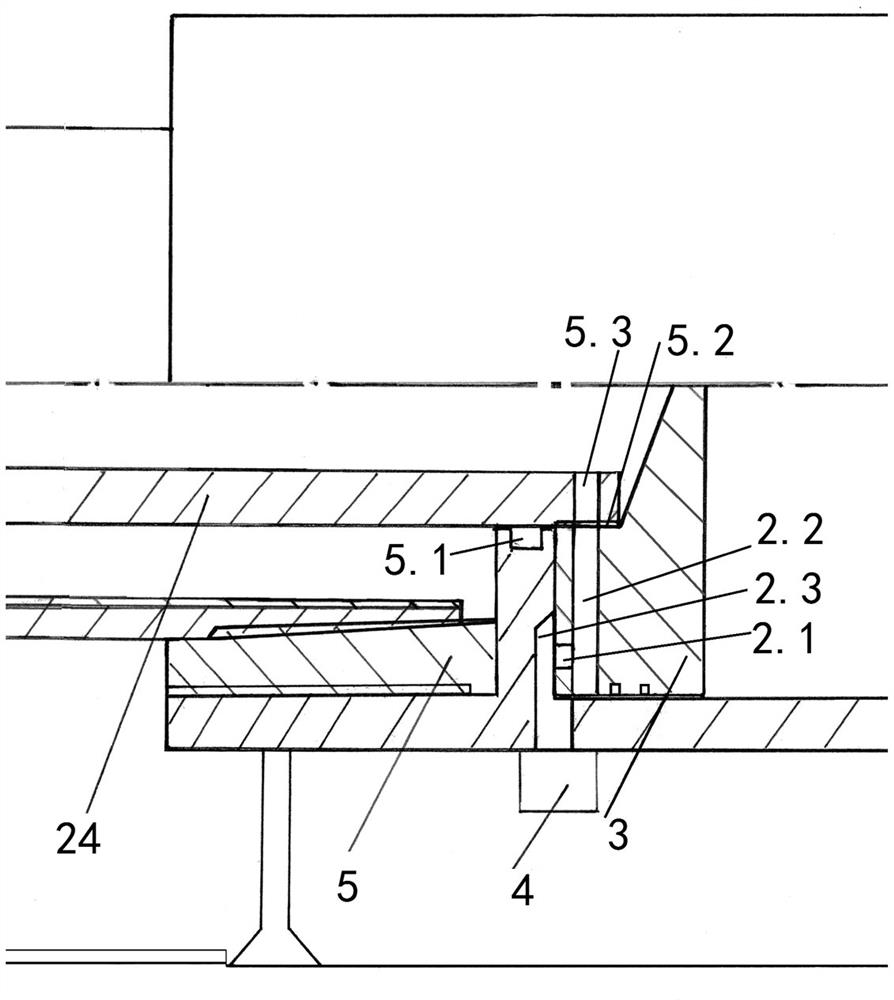

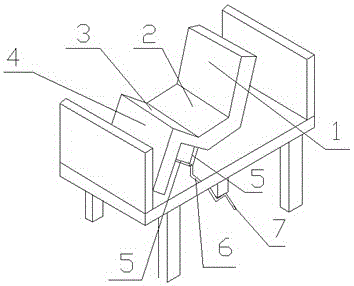

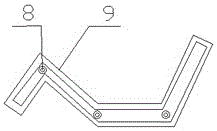

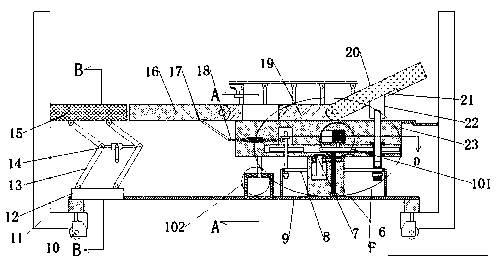

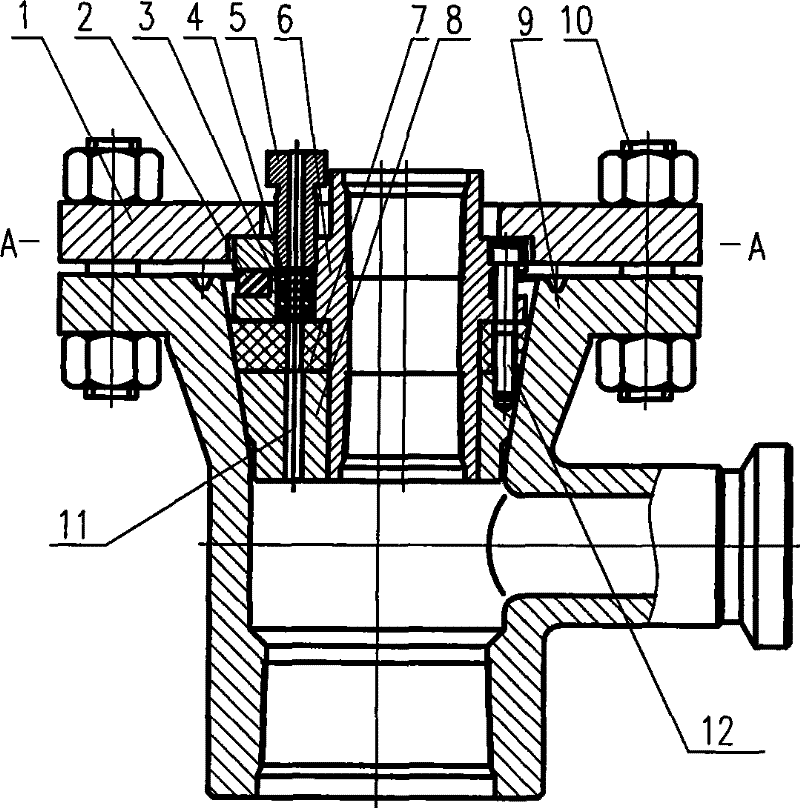

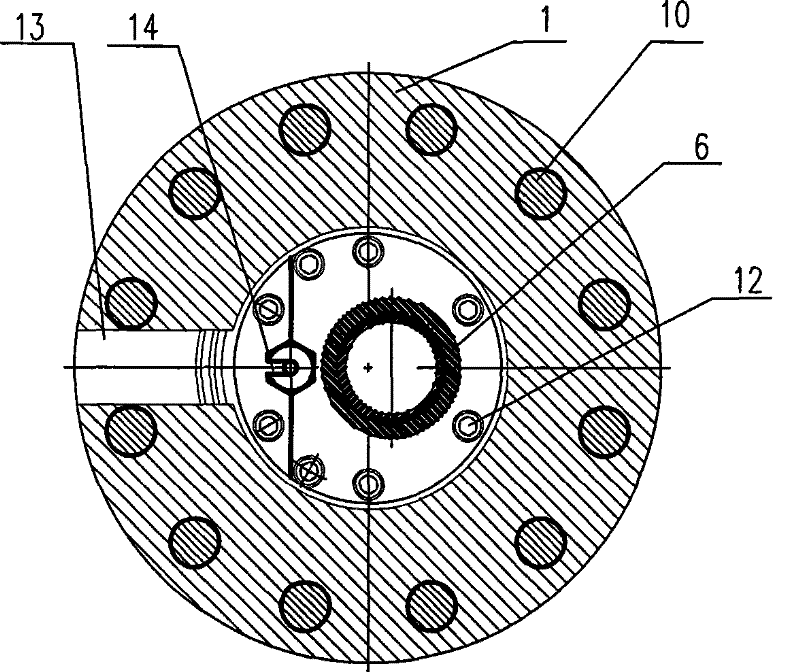

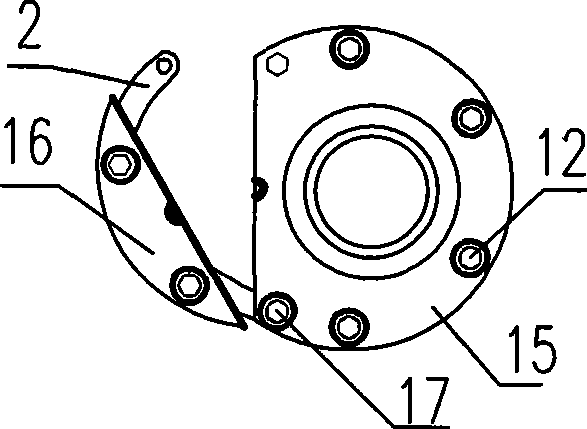

The invention relates to a mechanical recovery horizontal well preset produced fluid profile testing method and a special wellhead testing device thereof, mainly aiming at solving the problem of the downhole testing of a mechanical recovery horizontal well. The invention is characterized in that: the special wellhead testing device comprises an eccentric type tubing hanger body connected with a tubing string, wherein, the side wall of the tubing hanger body is divided into a body and splits which are completely matched with each other, and the splits are fixed on a locking arm which is fixed on the body though bolts; and a corresponding matched cable penetrating a channel is arranged at the splitting seam of the body and the splits, the channel is internally provided with a cable gasket, a spacer and a pressing cap. By being matched with a special wellhead support, under the condition that a testing cable and a tester are pre-arranged in the horizontal well to test a target layer, an oil pipe does not touch the cable during the up and down process of the oil pipe. The method and the special wellhead testing device can realize the produced fluid profile testing of the mechanical recovery horizontal well, and ensure the accuracy of normal testing and data of the mechanical recovery horizontal well with simple and reliable operation method.

Owner:DAQING OILFIELD CO LTD +1

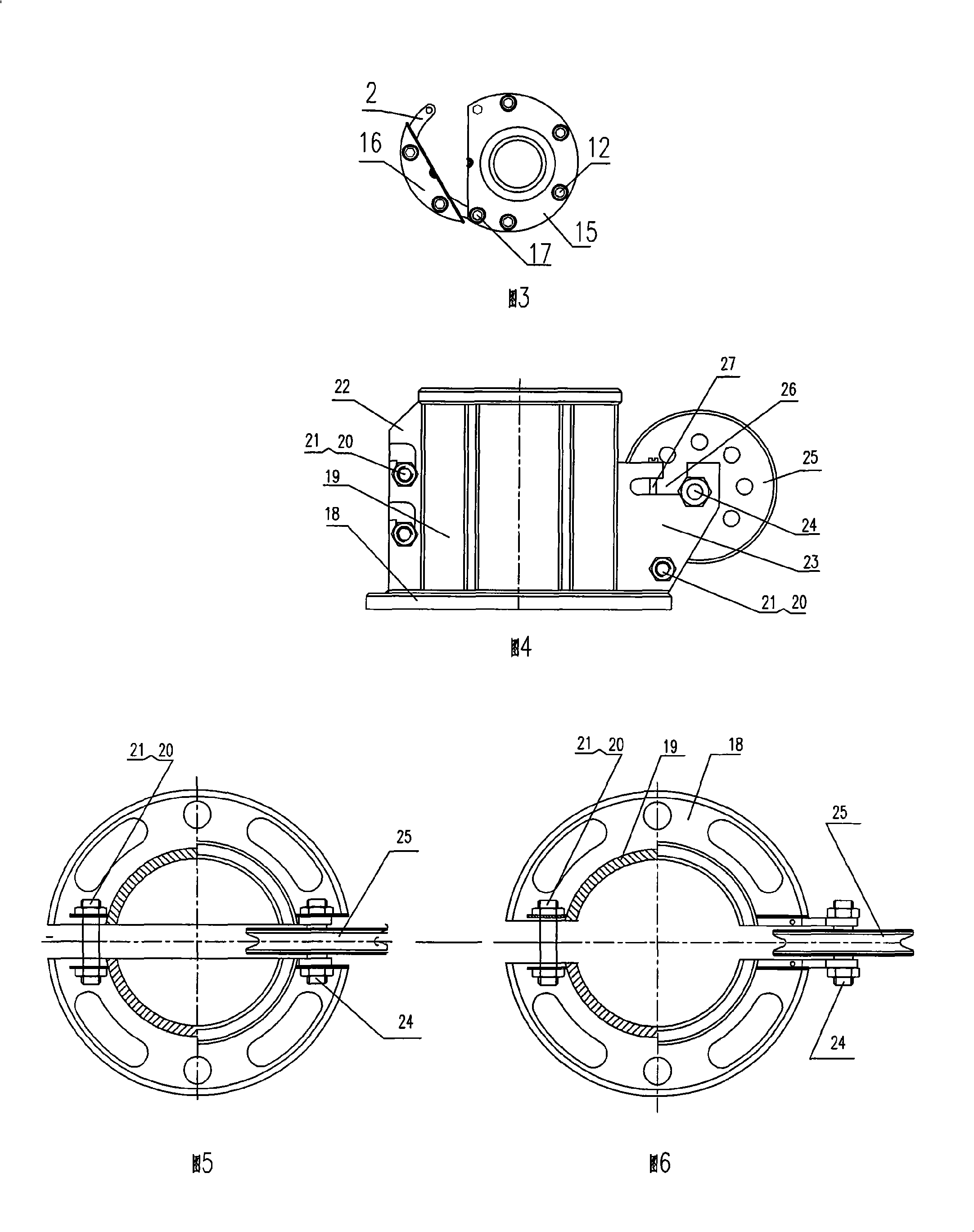

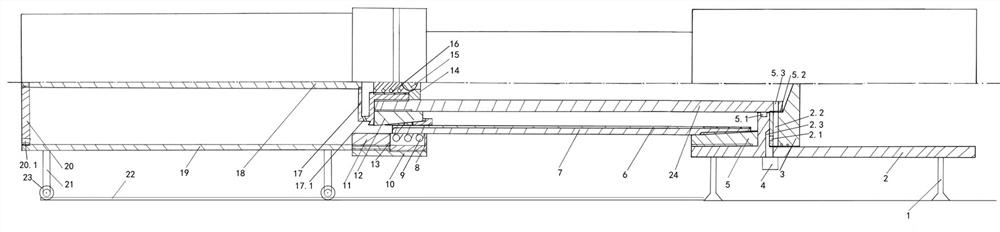

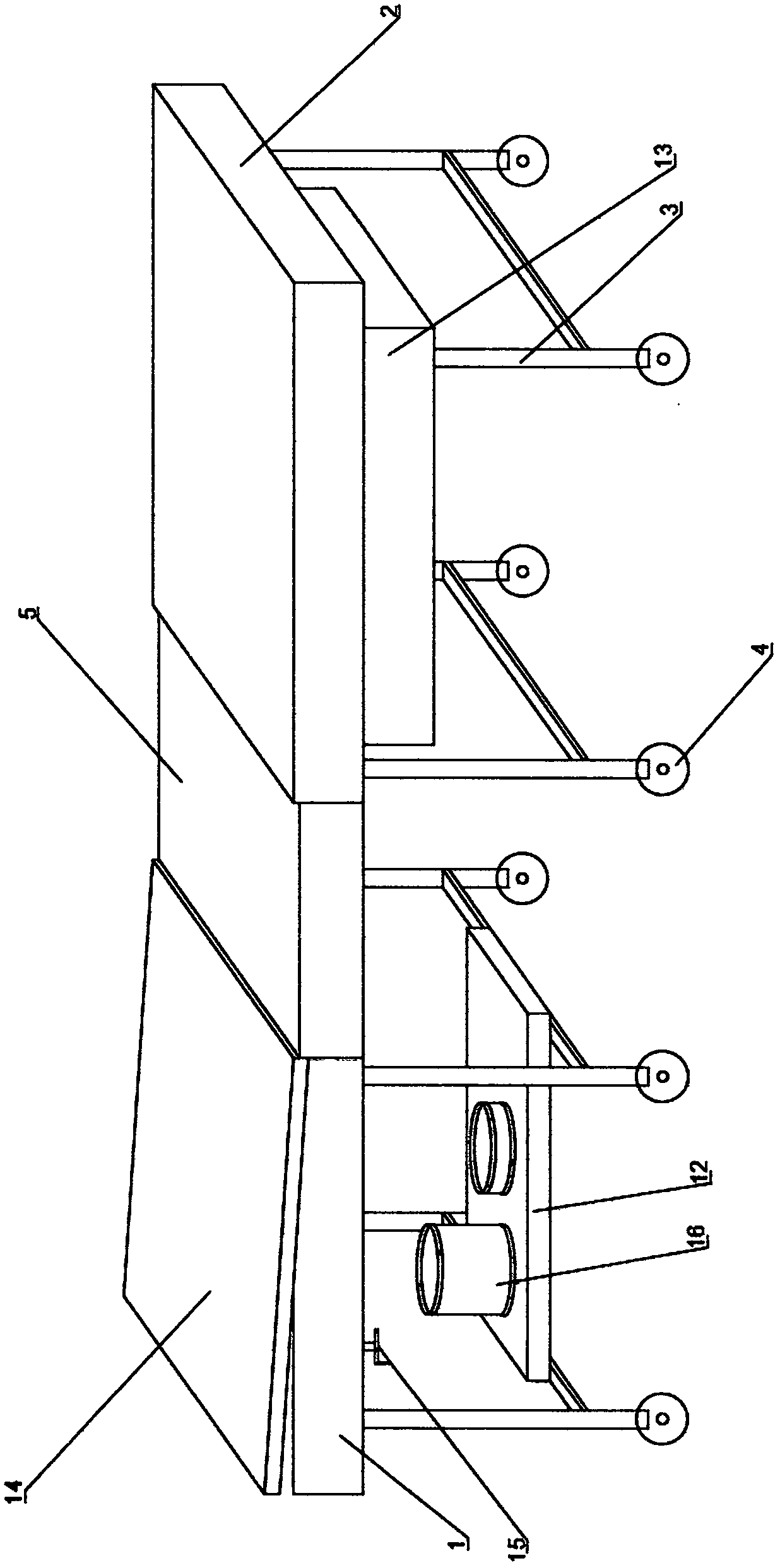

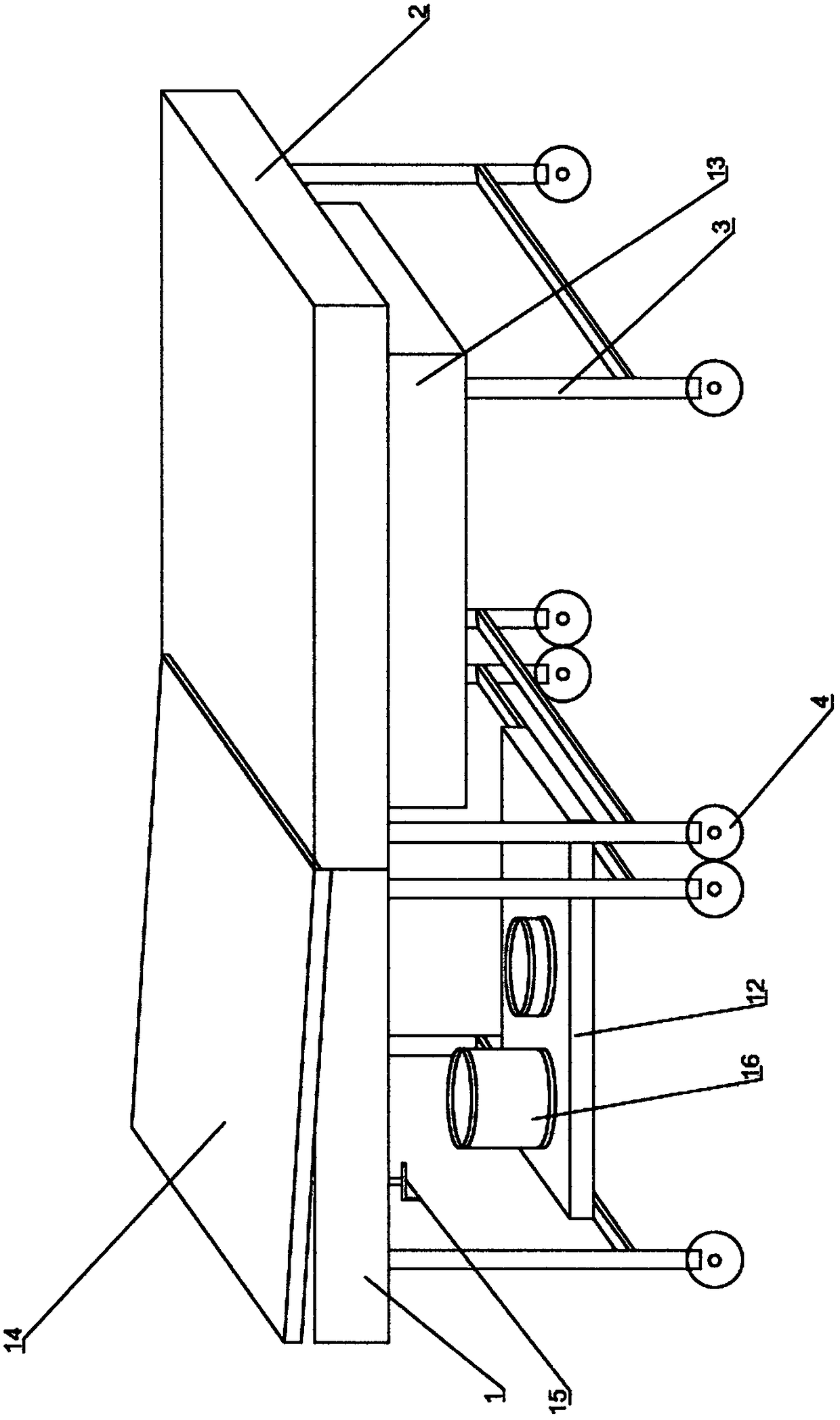

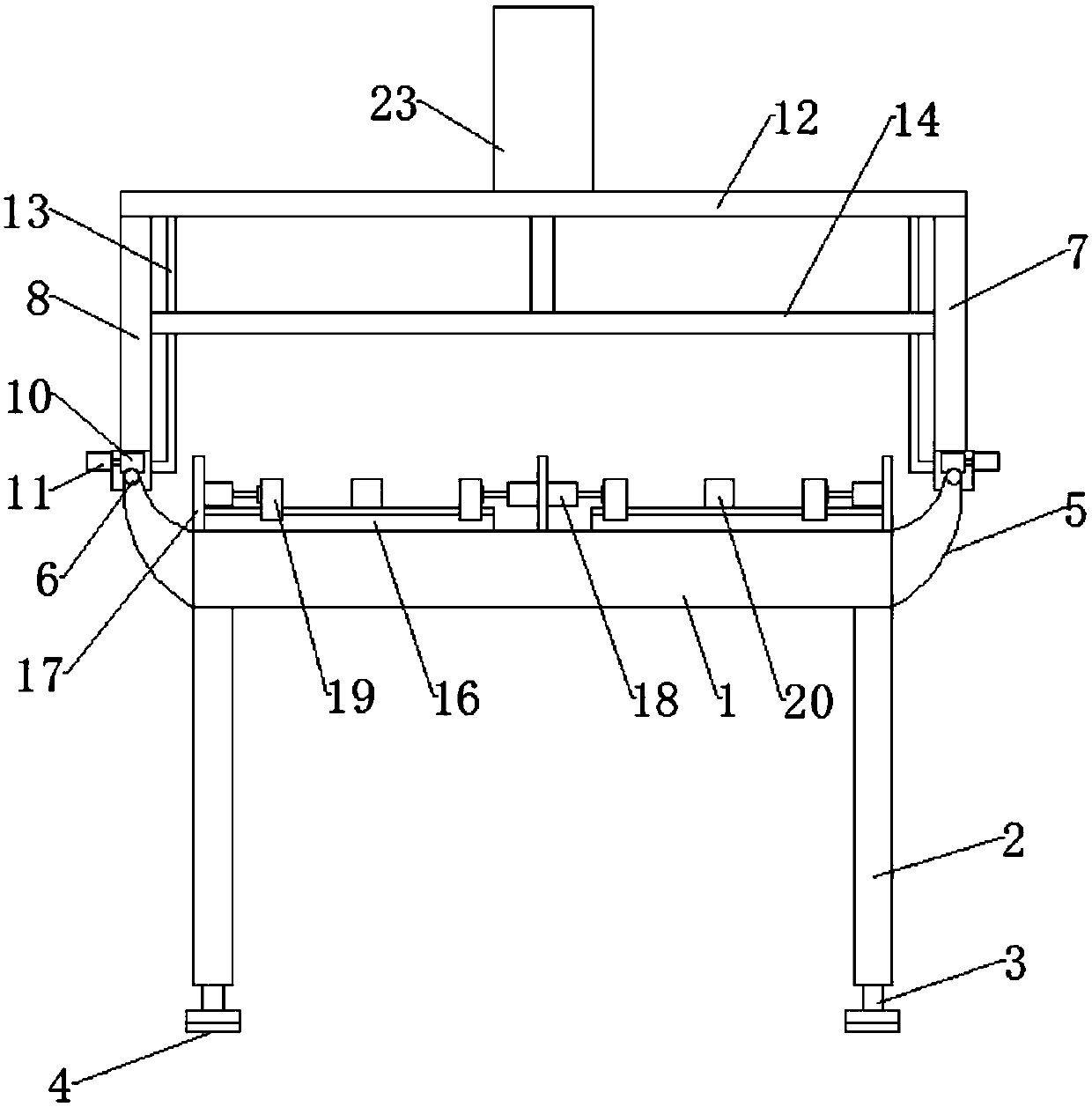

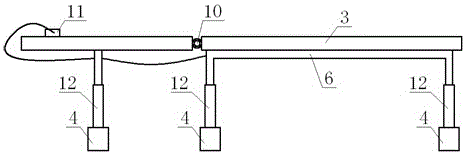

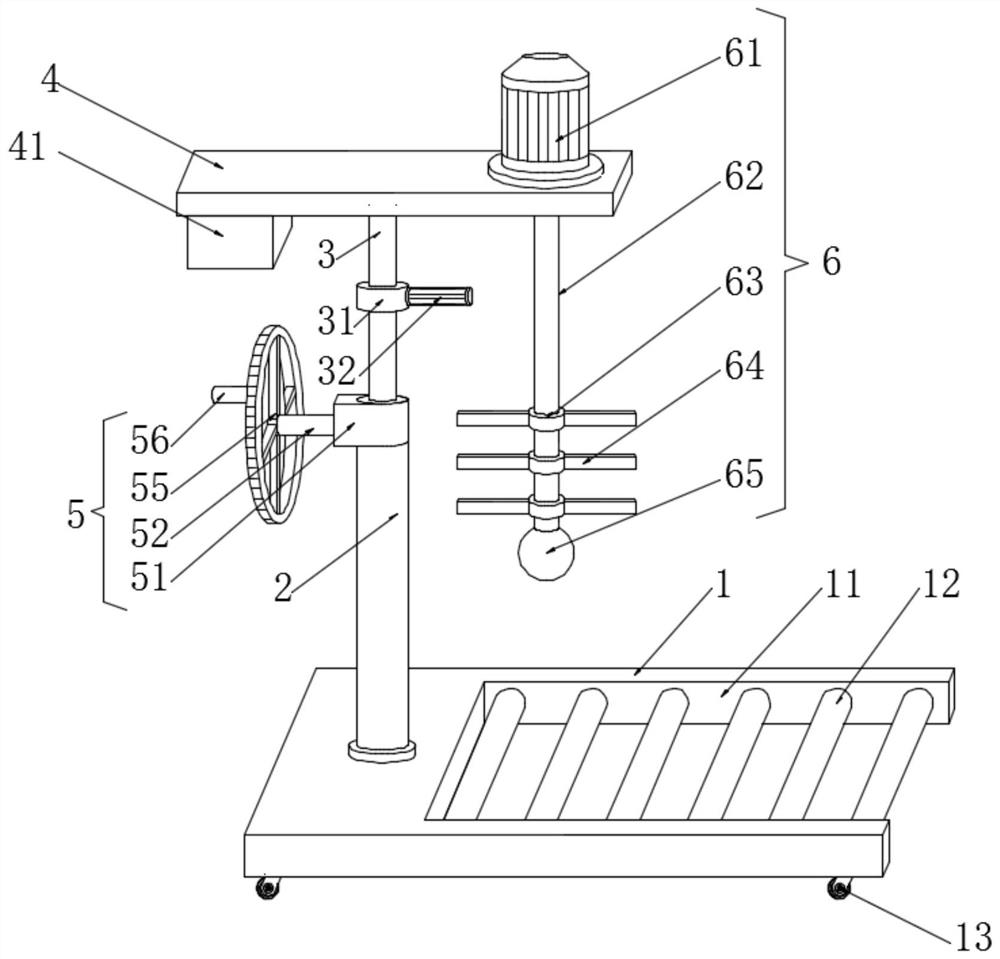

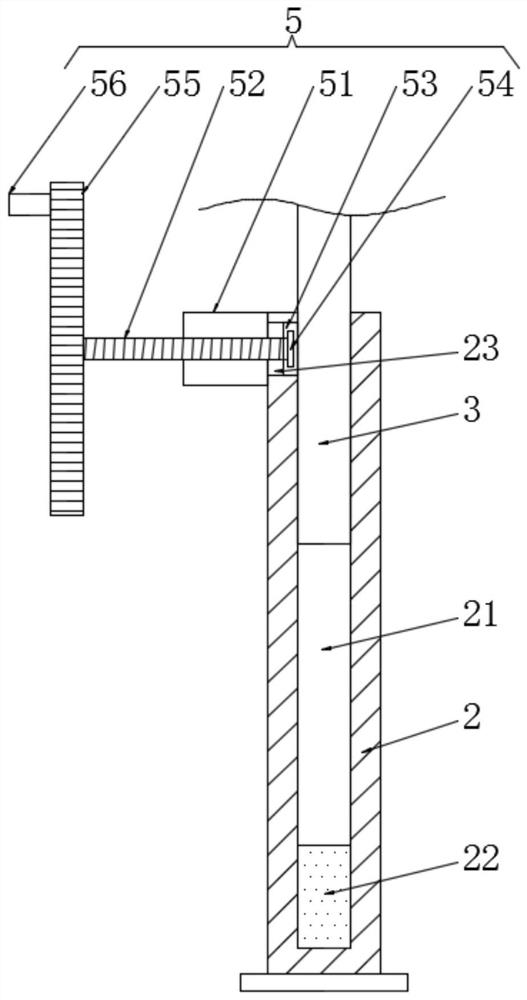

Laparoscope holding fixer

InactiveCN101569556AEasy to get up and downEasy to moveSurgical furnitureLaproscopesAbdominal cavitySpherical joint

The invention discloses a laparoscope holding fixer designed to solve the technical problem of holding the laparoscope head for a long time and facilitate flexible fixation of the position and direction of the laparoscope head so as to benefit operation and save labor. The technical proposal is as follows: a laparoscope holding fixer comprises a fixer component which is composed of a bracket seat, a bracket pole and a slide pole; the upper end of the bracket seat is connected with the bracket pole, one end of the bracket pole is provided with a regulating mechanism and the other end thereof is provided with a slide tube capable of sliding transversely, the slide pole is sheathed outside the slide tube transversely, a slide block is arranged on the slide pole vertically and is provided with a rotary fixing seat which is connected with the laparoscope. Compared with the prior art, the laparoscope head is fixed at the upper part of the fixing seat and the lower part of the fixing seat is connected with a spherical joint of the slide block flexibly, so that the whole structure can lead the laparoscope head to move or rotate up and down, left and right and back and forth, thus facilitating watching and observing of all the parts of the abdominal cavity and playing the role of holding the laparoscope.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

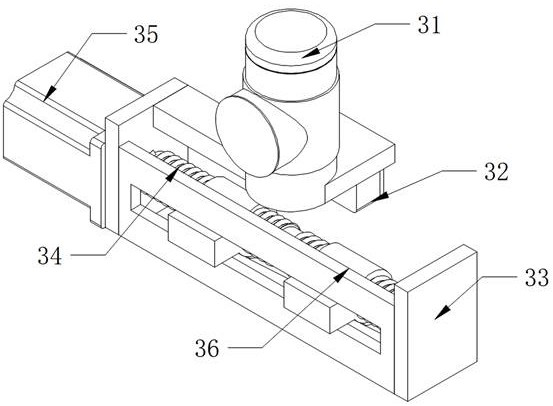

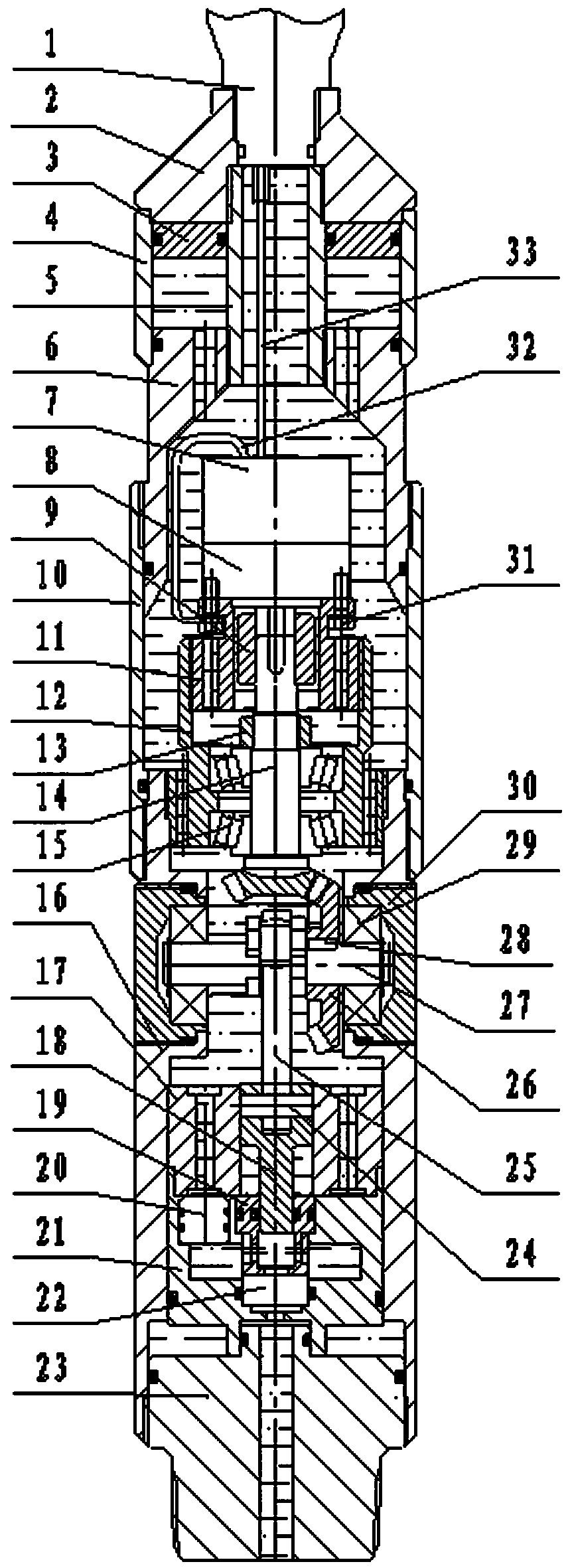

Fishable linear motor reciprocating pump

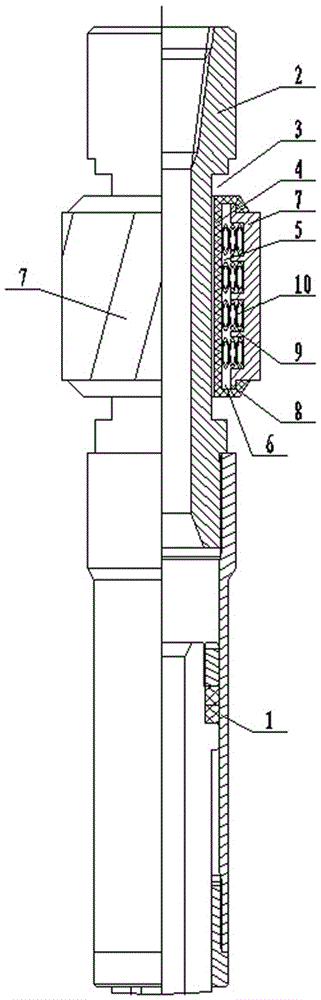

The reciprocating pump in use for oil spring is composed of cable, a pump, anchoring sealing arrangement, linear motor, and oil pipe. Linear motor is cylinder type permanent magnet linear synchro motor. Motor is composed of stator and mover. Stator is a winding, and mover is a permanent magnet. Through connecting rod, mover of linear motor is connected to plunger of reciprocating pump. Reciprocating pump is positioned at up part of the linear motor. The anchoring sealing arrangement plays function of fixation and seal. Through release drum, oil well pump and inner core of linear motor are seated on sealed drum of the anchoring sealing arrangement, and are possible to be picked out through junk basket, but cable can remain under well. The invention crates new structure of reciprocating pump, and solves difficulties that it must pick cable up or put cable down at same time when reciprocating pump is picked up or put down.

Owner:中国石油化工股份有限公司河南油田分公司石油工程技术研究院 +1

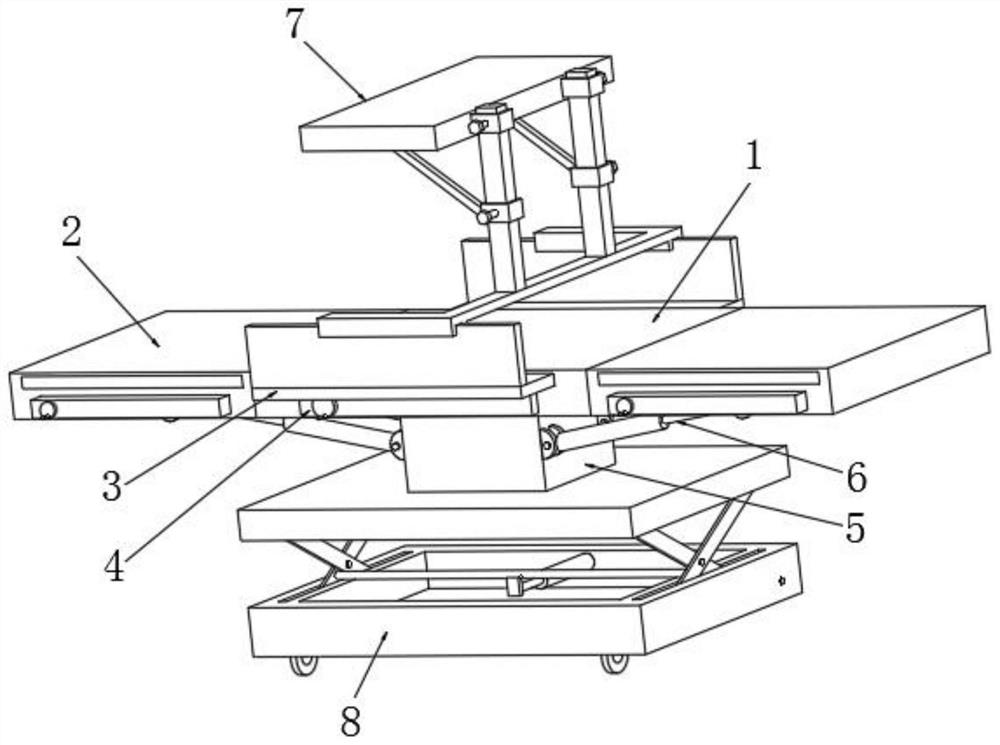

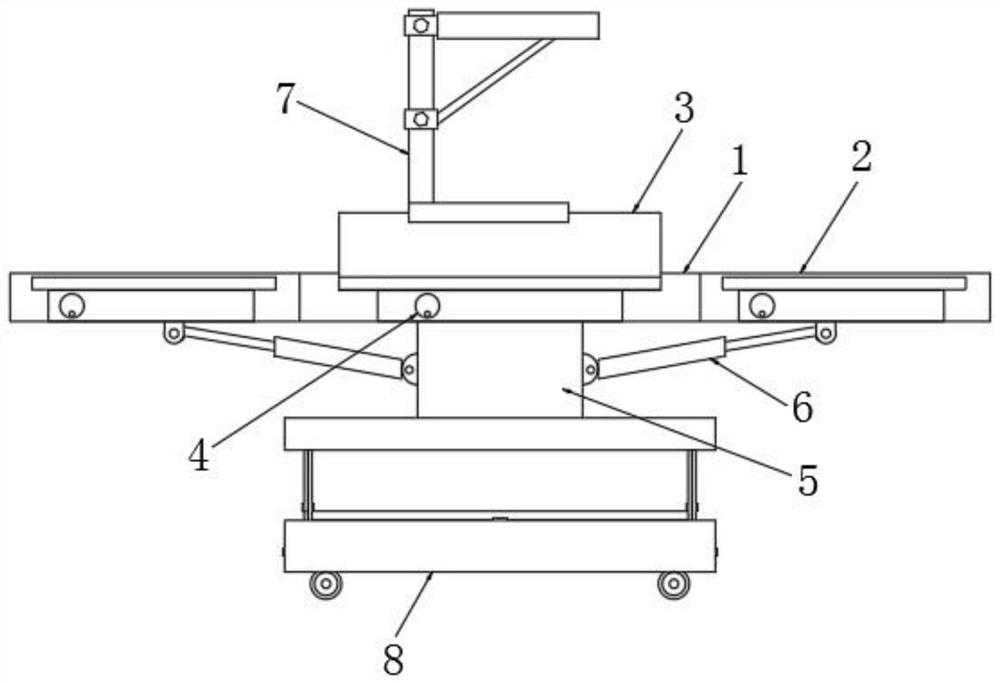

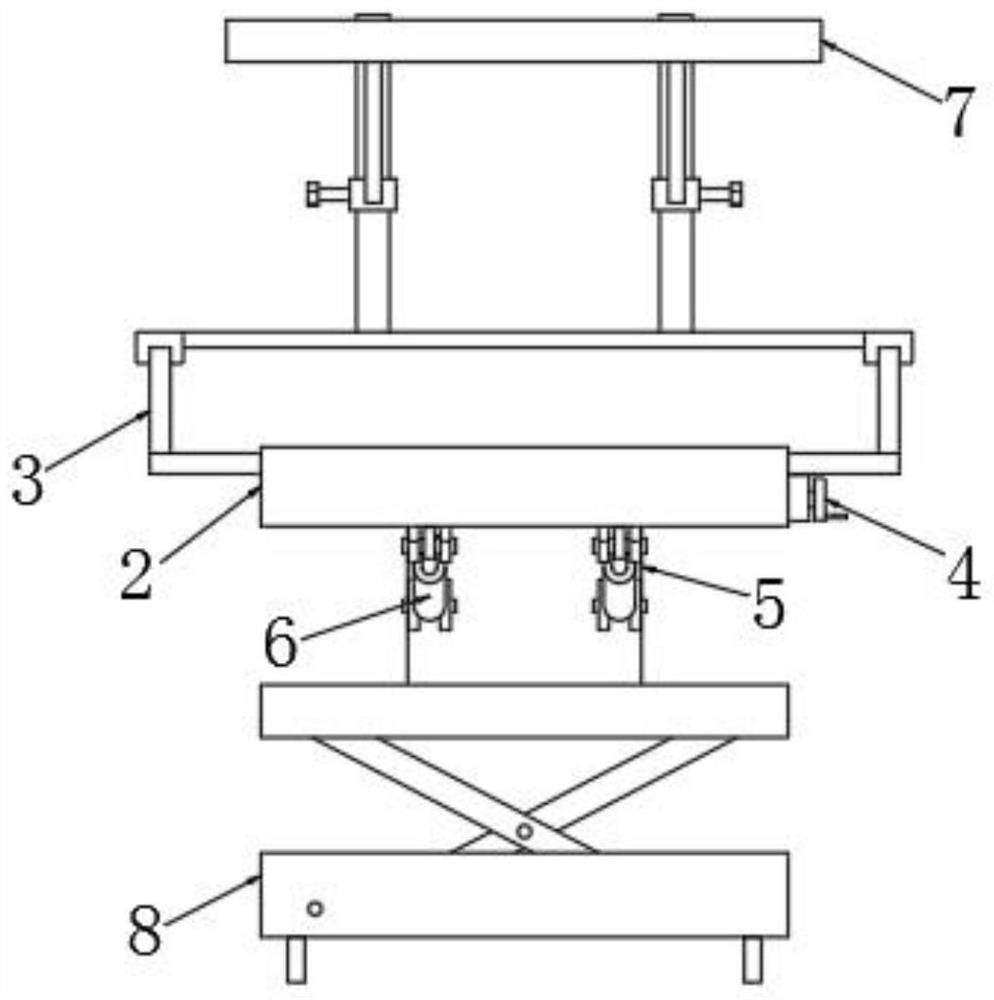

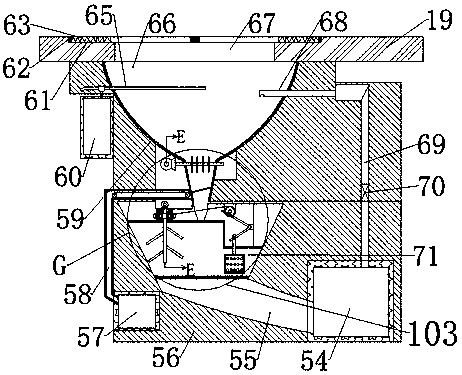

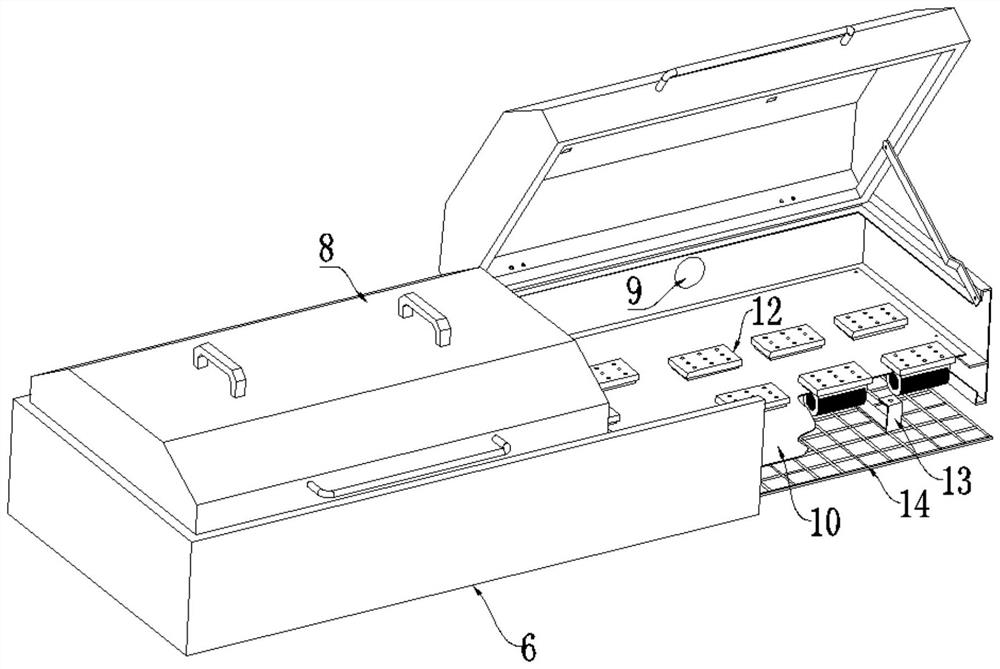

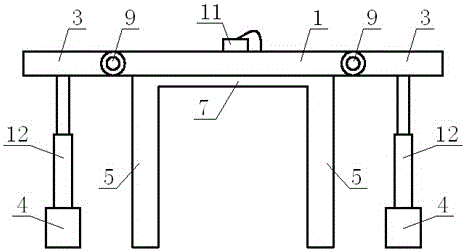

Elevating kidney stone therapeutic apparatus with supporting device

InactiveCN107854157AEasy to get up and downEasy to slapOperating tablesMedical equipmentKidney stone

The invention discloses a liftable kidney stone treatment apparatus with a support device in the technical field of medical equipment, comprising a movable plank bed, a pillow is arranged on the top of the movable plank bed, and a fixed plank bed is arranged at the right end of the movable plank bed. The movable plank bed and the fixed plank bed are connected by hinges, the top of the fixed plank bed is provided with a support device, the top of the support device is provided with a sliding support frame, the front and rear side walls of the fixed plank bed are provided with chute, the sliding support The bottom inner wall of the frame is provided with a sliding block matched with the chute. In the present invention, a movable plank bed, a limit block, a lifting screw, a rotating screw and a manual crank are arranged, and the rotating screw is driven to rotate by the manual crank, and the rotating screw and the lifting The screw is matched to make the lifting screw move up and down, and the lifting screw drives the angle adjustment of the movable plank, which is convenient for the patient to get up and down.

Owner:青岛恒科瑞新信息科技有限公司

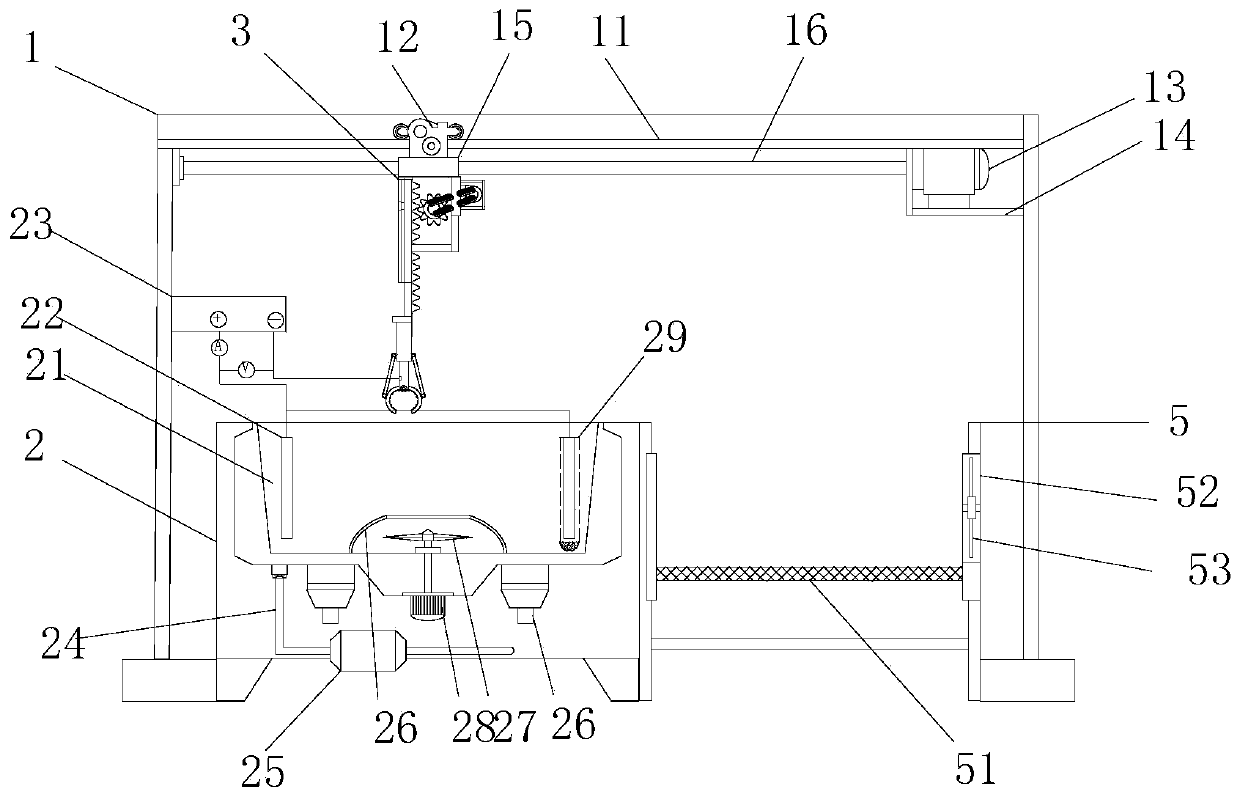

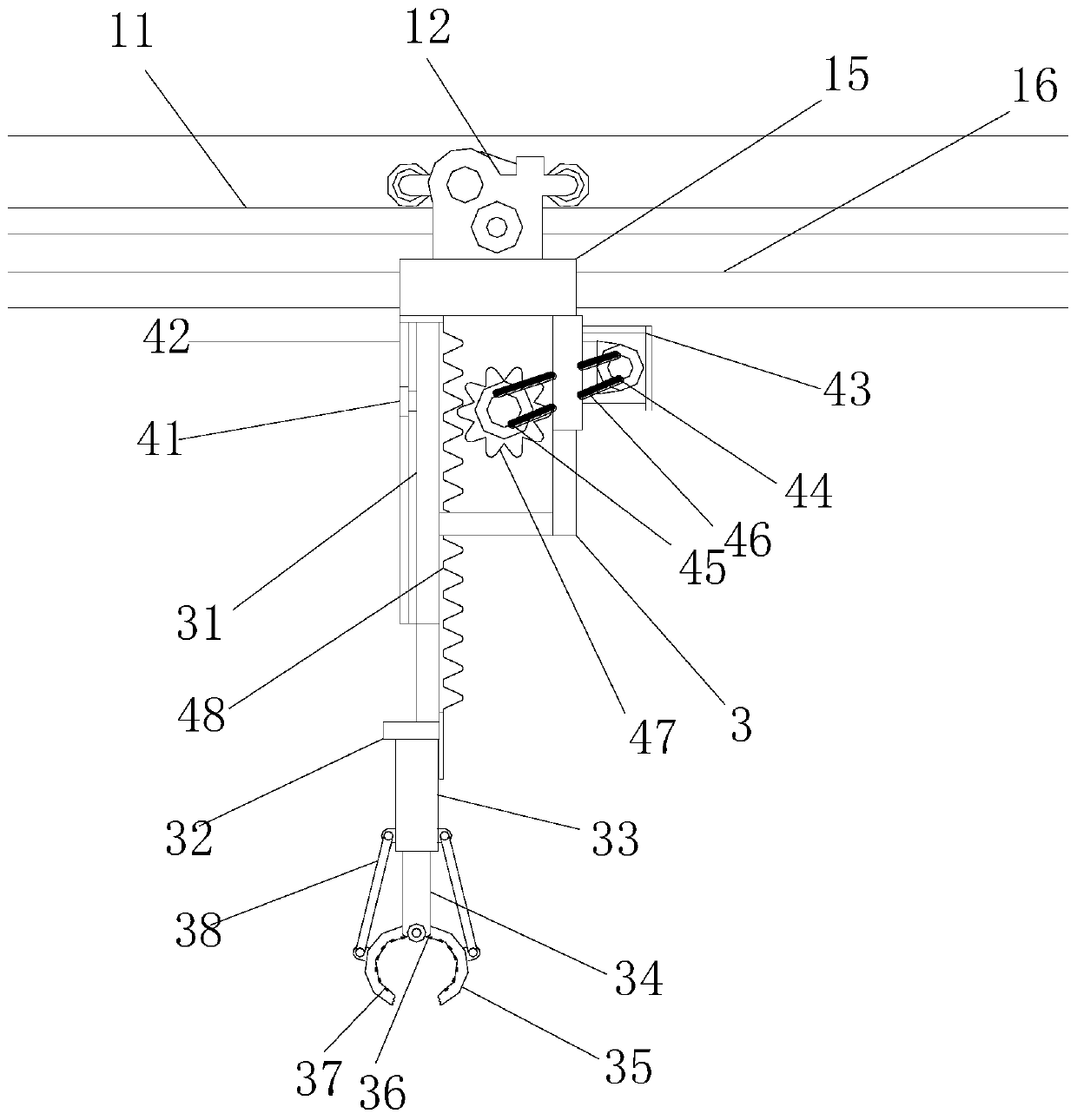

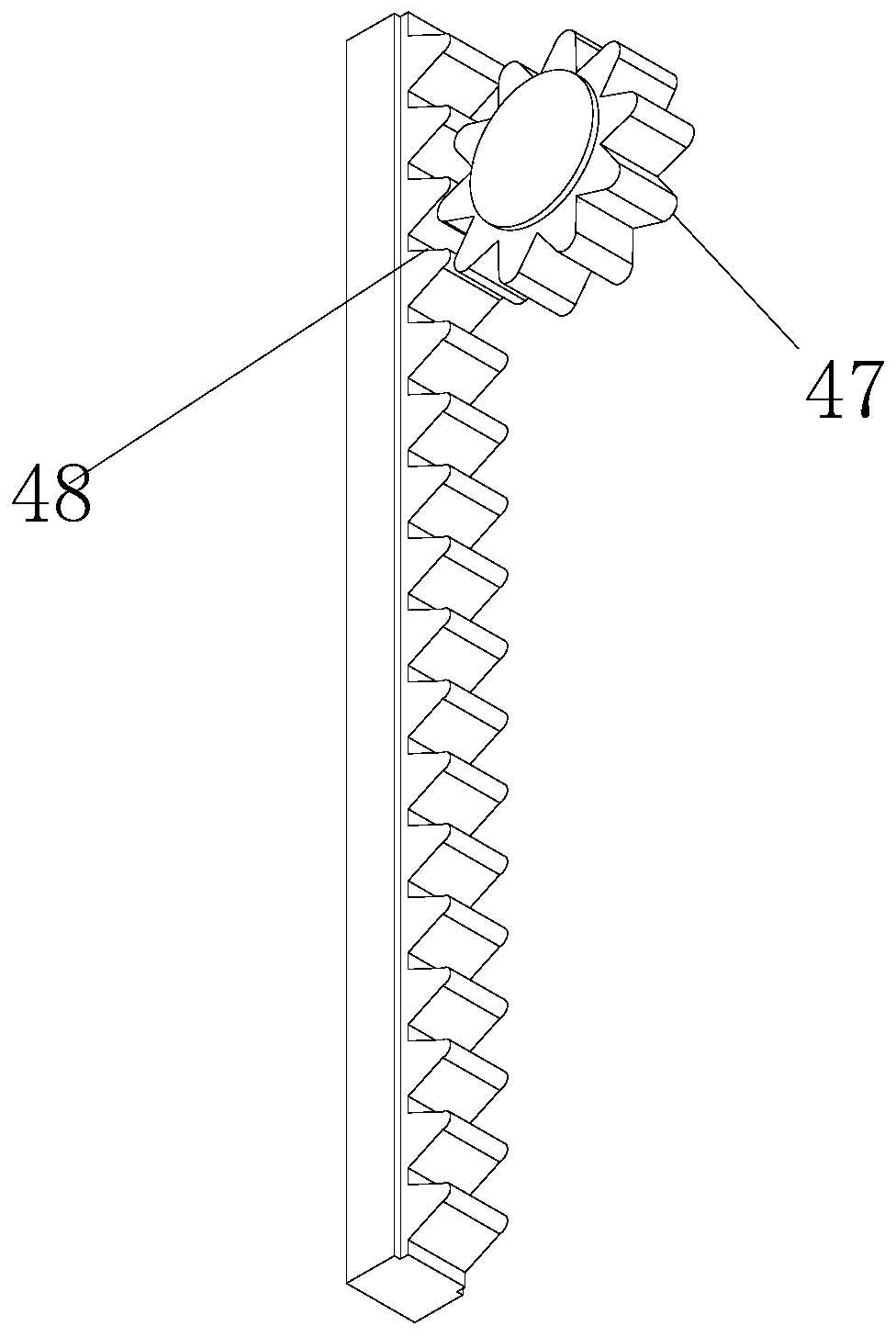

Electroplating device for plastic automobile ornaments

InactiveCN110724986AAvoid collisionCost recoveryCellsTanksElectrical connectionStructural engineering

The invention relates to the technical field of electroplating, and particularly relates to an electroplating device for plastic automobile ornaments. The device comprises a rack, wherein the bottom of the rack is provided with an electroplating box and a storage cavity, a lifting frame is movably mounted on the rack, an electroplating pool is arranged in the electroplating box, the electroplatingpool is internally provided with electroplating liquid, the bottom of the electroplating pool is externally connected with an infusion duct, a booster pump is installed on the infusion duct, a powersupply is installed on the side edge of the rack, a positive electrode of the power supply is connected with metal pieces through a plurality of electrical connecting wires correspondingly, the metalpieces are located in the electroplating pool, a workpiece clamped on the lifting frame is connected with a negative electrode of the power supply through an electric connecting wire, the lifting frame is arranged on the rack, a lifting plate is mounted on the lifting frame, and a clamping frame is installed at the bottom end of the lifting plate. According to the device, through the transfer of metal ions, the electroplating treatment on the surface of the workpiece is completed, and the effect of three-dimensional azimuth adjustment can be achieved.

Owner:阮松益

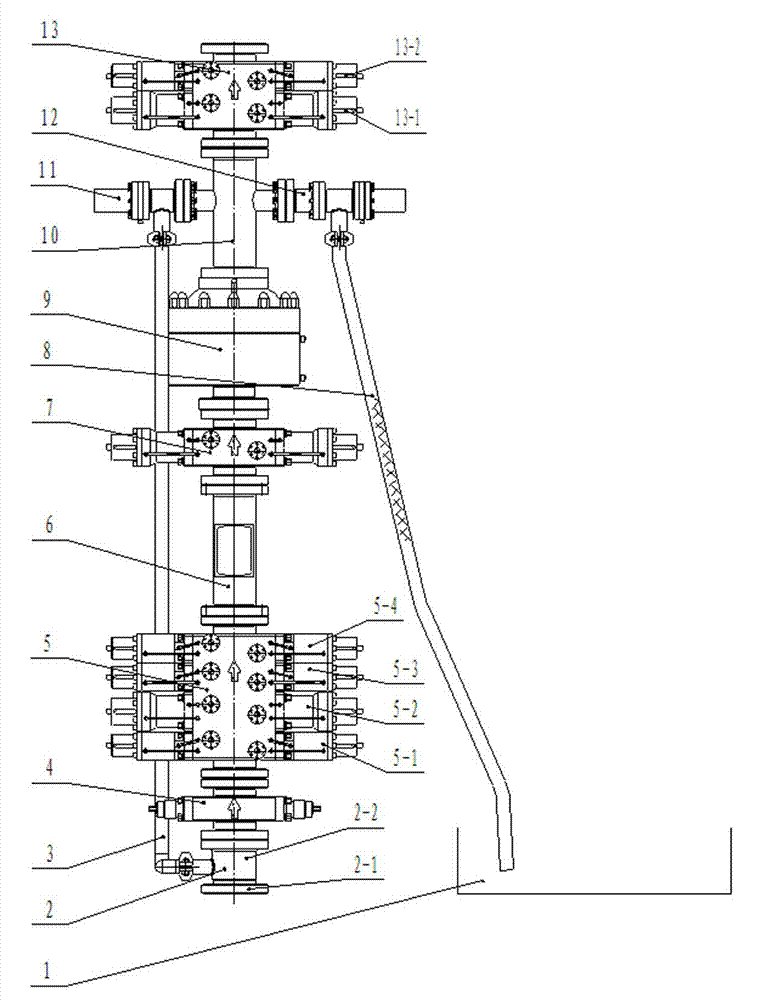

Blowout-prevention tool string of belt pressure energy storage well repairing machine

InactiveCN102817571AEasy to observe the sealing conditionAvoid pollutionSealing/packingLine tubingControl engineering

The invention discloses a spraying-prevention tool string of a belt pressure energy storage well repairing machine, and the blowout-prevention tool string of the belt pressure energy storage well repairing machine is matched with a belt pressure energy storage well repair machine. The tool string comprises a four-ram blowout preventer, a shearing blowout preventer, a balancing device, an emptying device and a dual-ram blowout preventer; and the emptying device is connected with a sewage discharge pipeline. The tool string is sequentially connected with a rotary mechanism, a manual centering guide, the four-ram blowout preventer, a connecting platform short joint, the shearing blowout preventer, an annular blowout preventer, a lifting short joint, the balancing device, the emptying device and the dual-ram blowout preventer from bottom to top; and one end of the balancing pipeline is connected with the balancing device, and the other end of the balancing pipeline is connected with the rotary mechanism. The rotary mechanism enables the tool string to be strung on a part at any angle and to align with a well opening; when the manual centering device discharges a pipe column, the pipe column can be centered to the center of the well opening, and the manual centering device has an anti-clamping effect; and the blowout preventer is provided with a secondary seal structure, the secondary seal structure is not only convenient to operate, but also can reduce the pollution to the environment at the same time; and the service life of a device is prolonged, and the production cost is lowered.

Owner:东营鸿昇机械设备有限公司

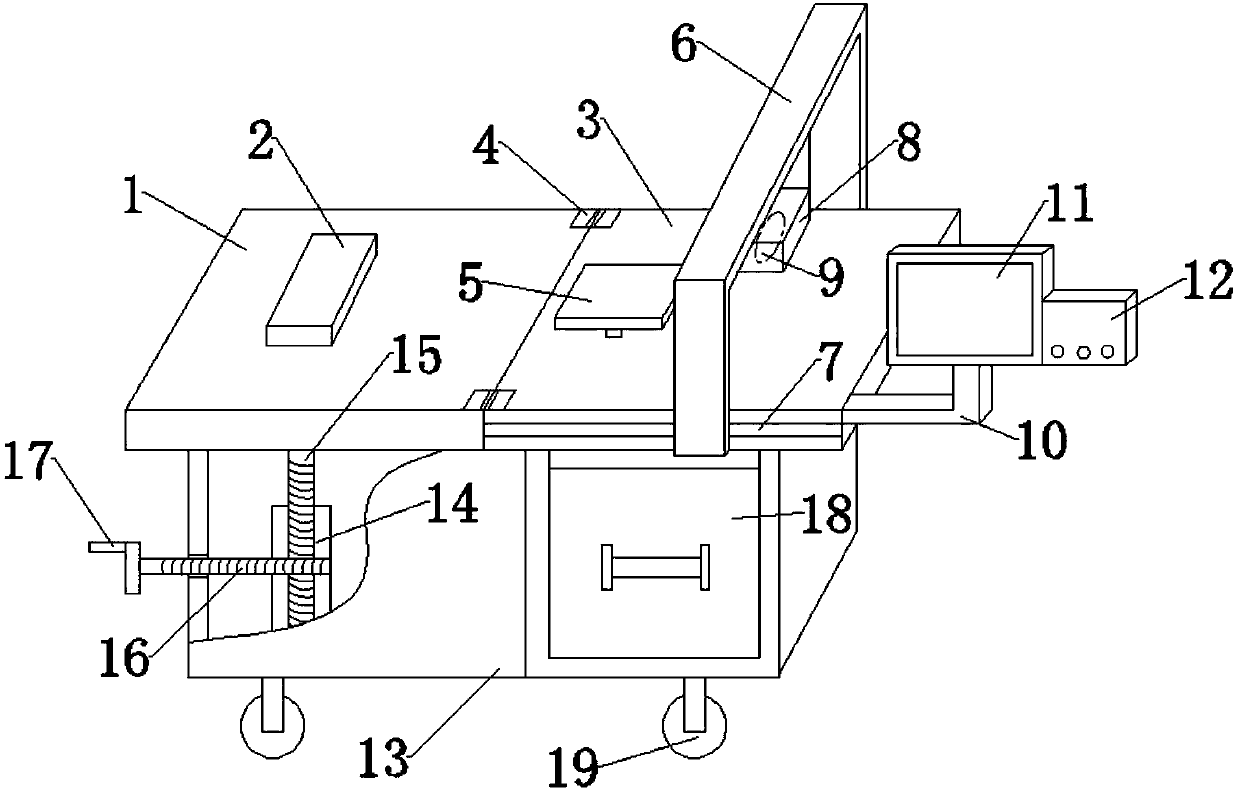

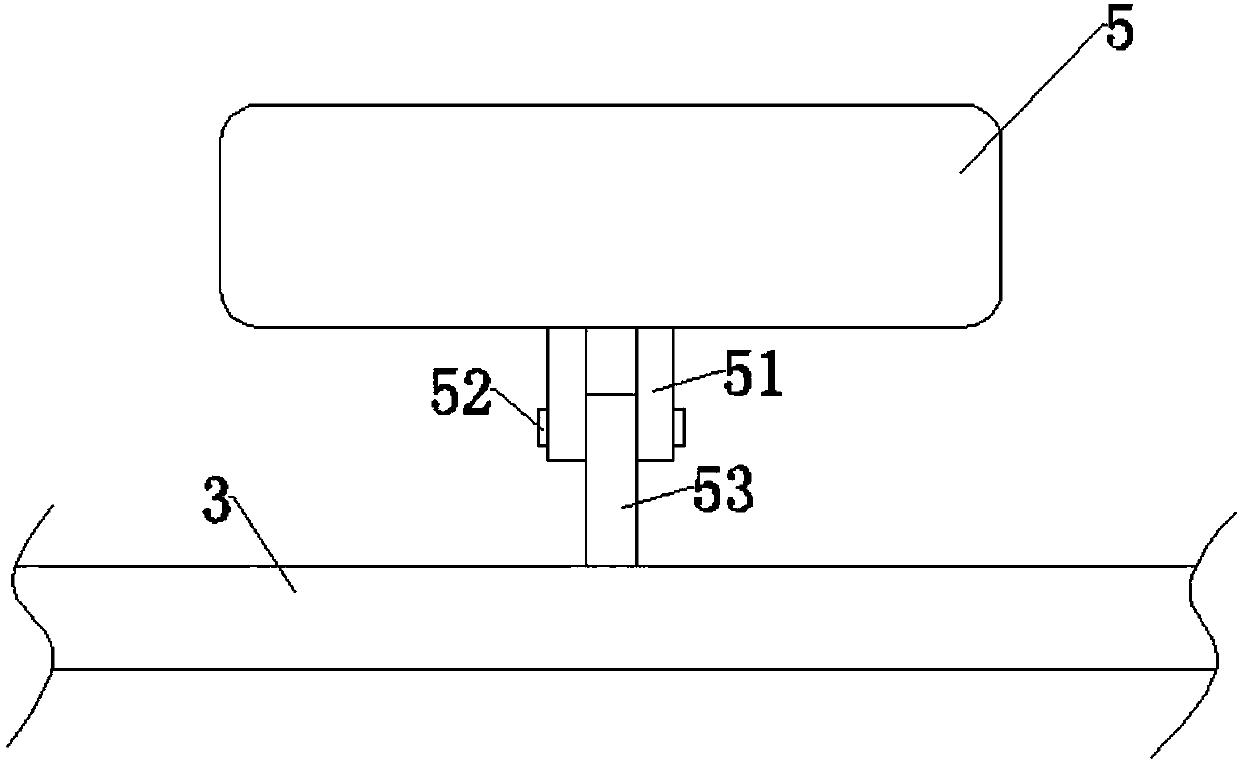

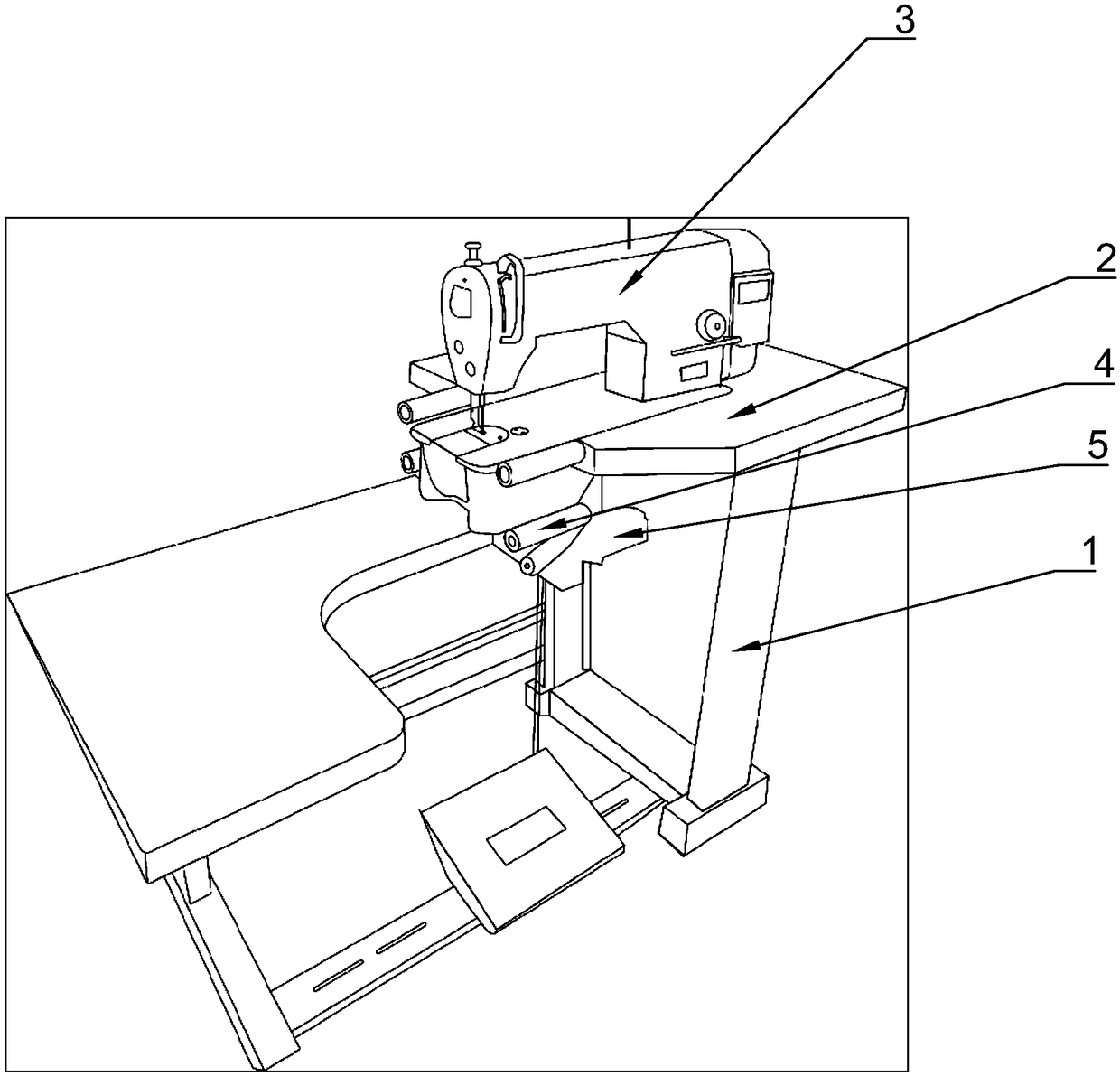

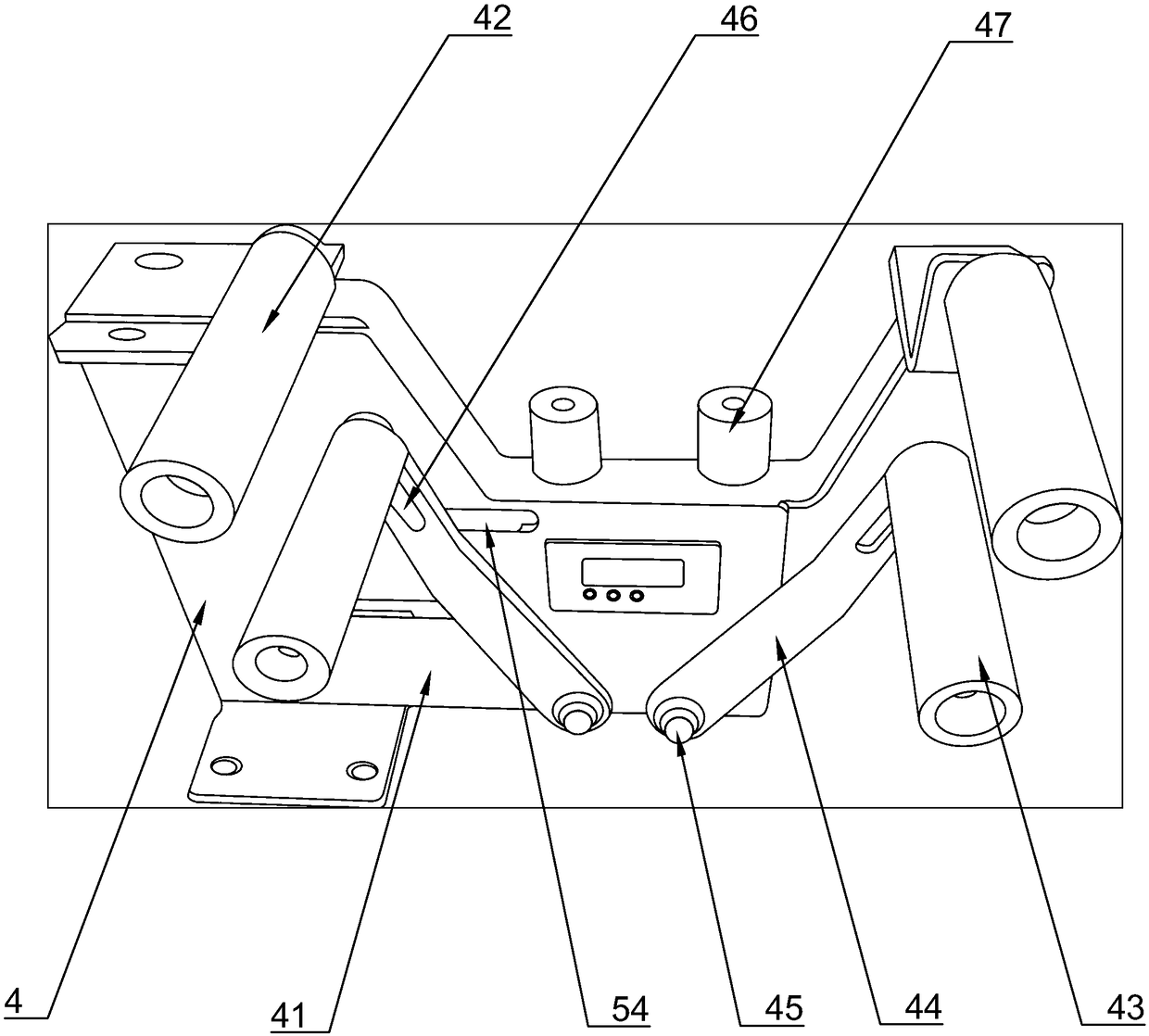

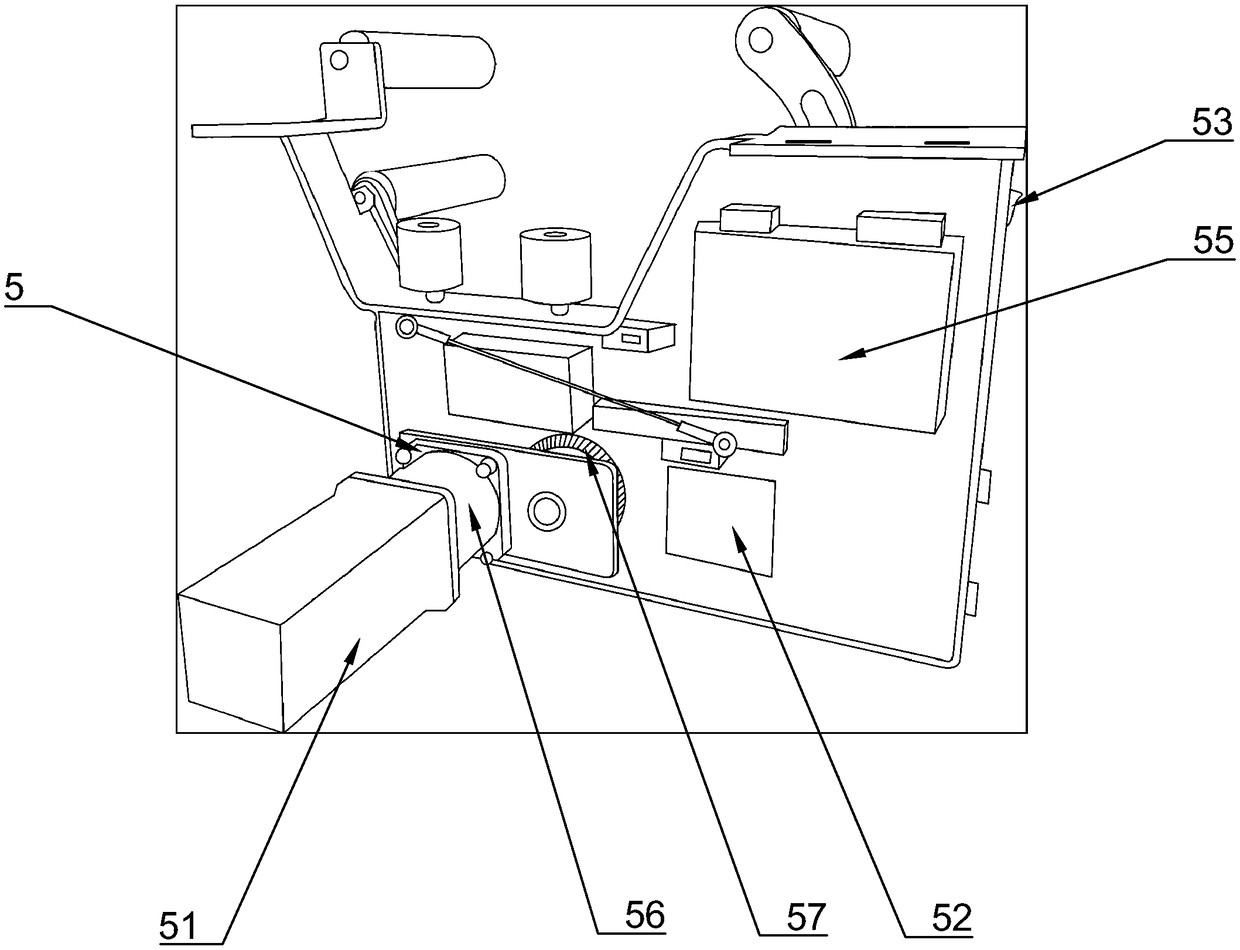

Sewing device capable of loosening and tightening trouser waists

The invention discloses a sewing device capable of loosening and tightening trouser waists. The device is characterized by comprising a rack, a work table horizontally arranged on the rack and a sewing machine head used for sewing the trouser waists, the sewing machine head is arranged above the work table, and a strutting assembly used for strutting the trouser waists is arranged on the lower surface of the work table; the strutting assembly comprises a mounting plate fixedly connected with the lower surface of the work table, two fixed rolling rollers rotatably connected to the mounting plate and two movable rolling rollers close to or away from each other, the two fixed rolling rollers are respectively located at two sides of the work table in the width direction, and the movable rolling rollers are both connected with a mounting frame through swing arms; the ends of the swing arms are hinged to the mounting plate, the other ends of the swing arms are rotatably connected with the movable rolling rollers, and one side, back on to the fixed rolling roller and the movable rolling rollers, of the mounting plate is provided with a drive assembly used for driving the swing arms to reverse. The sewing device capable of loosening and tightening the trouser waists can be applicable to the trouser waists with different sizes, the application range is wide, sewing and loosening the trouser waists is convenient and labor-saving, and the sewing efficiency is high.

Owner:温州市利家缝纫科技有限公司

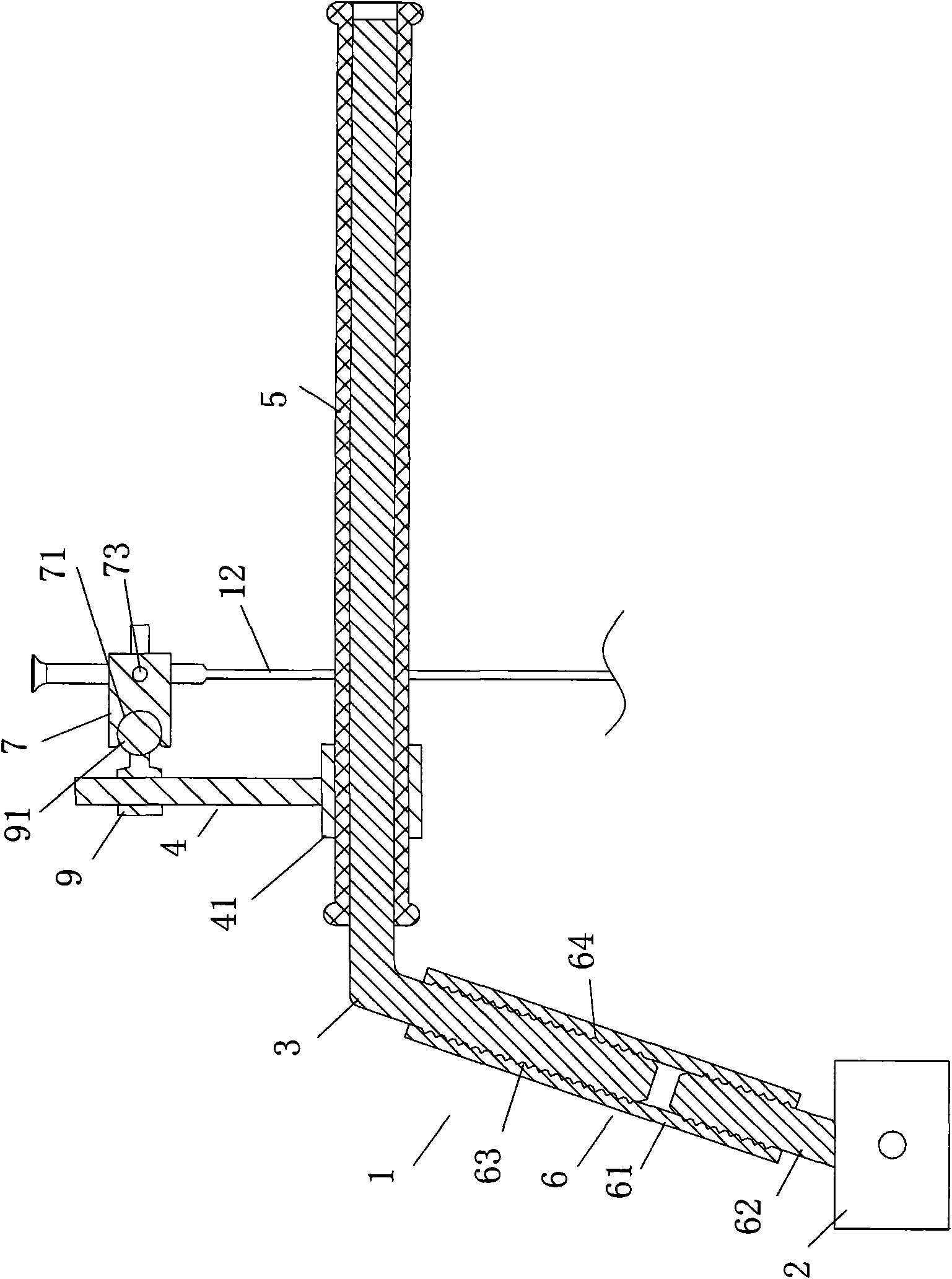

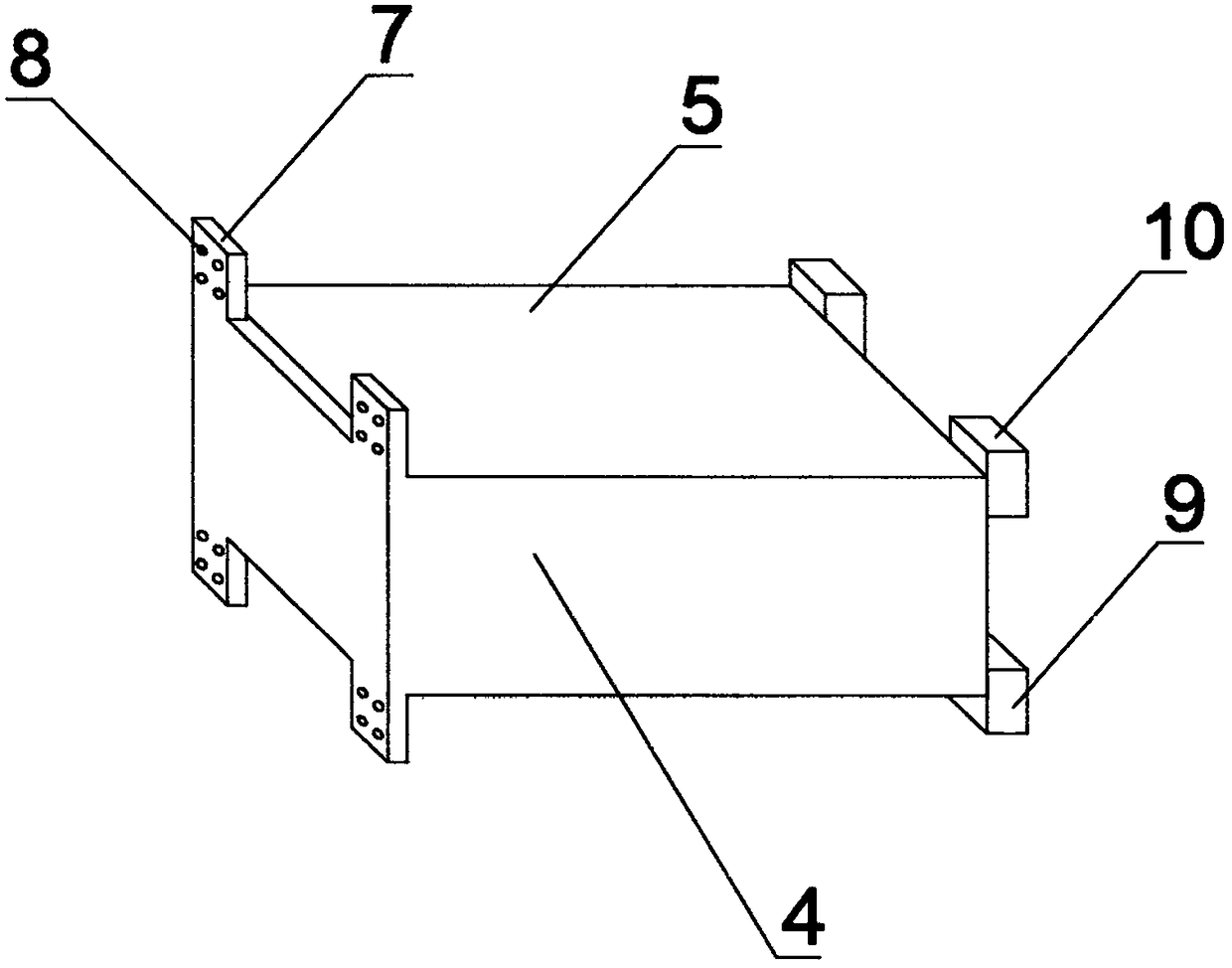

String tripping device

InactiveCN102926680ASimple structurePracticalDrilling rodsDrilling casingsEngineeringMechanical engineering

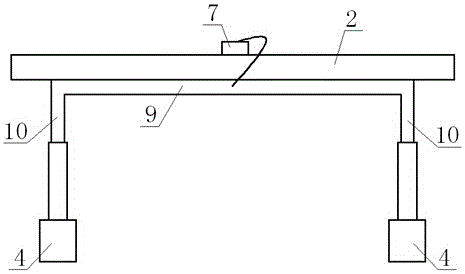

The invention discloses a string tripping device, which relates to a tripping device for tubing strings. The device comprises a supporting seat, a power cylinder is fixedly arranged on the supporting seat, a slip is movably arranged in the supporting seat, the slip is fixedly interconnected with the power cylinder, and the center of the slip is provided with a through hole. According to the string tripping device disclosed by the invention, through carrying out holding on a tubing string, the string can be tripped out of an oil-producing well conveniently. The string tripping device disclosed by the invention is simple in structure and strong in practicability.

Owner:SHAANXI QIYUAN TECH DEV

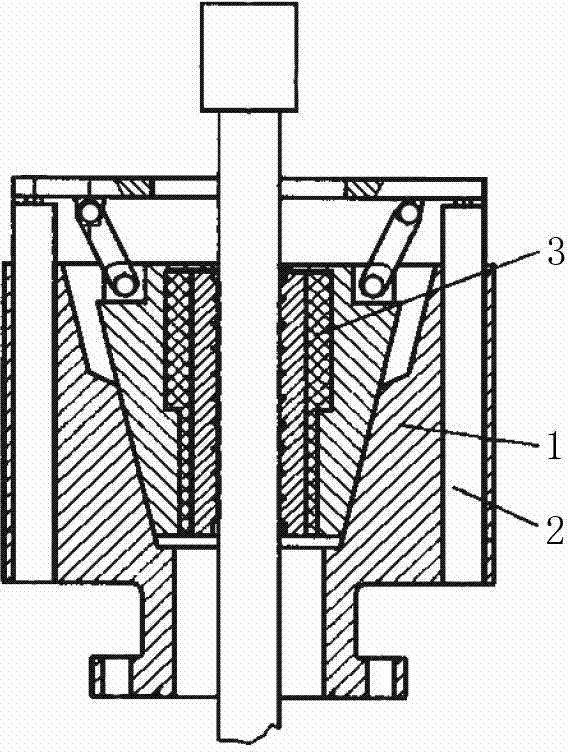

Compressed high-temperature packer with gas propelling

A compressive vapor impellent high-heated packer belongs to packer type of thick oil fill into underground well. This invention is advanced than the existing technologies, which is composed of upper adapter, central tube, tube of rubber, control ring, claw of support, cone, spring, liquid vat, back bonnet etc. When switch-in the underground well filler pipe, gas expand which is in the liquid vat of the outside of the central tube and the rubber tube expand into casing which is impelled by cone and claw of support, then rubber tube expand to the inside wall of the casing to achieve the sealed-off. The technology can avoid accessories drop into the well, save fund etc. The equipment can be used for improving series of packers in diameters of 102-150mm with casing of 5, 7 or 9 inch.

Owner:潘昌德

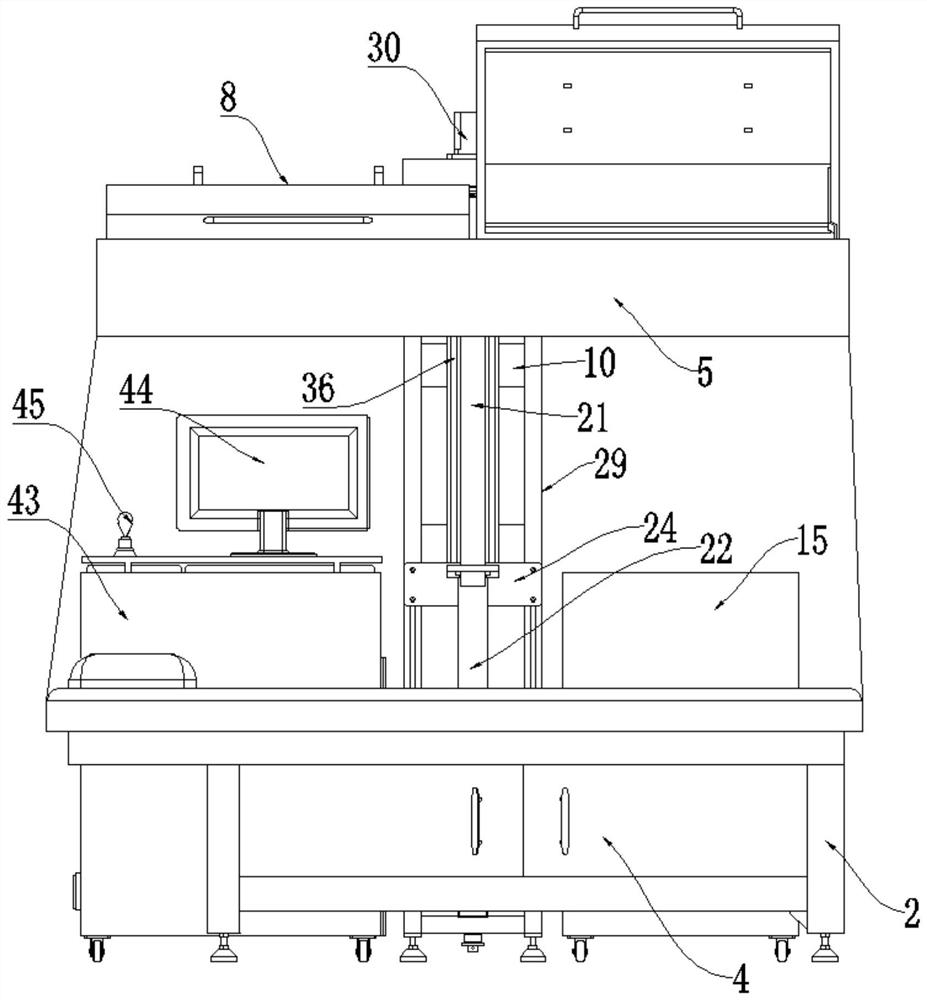

Preparation device of composite metal corrosion-resistant oil pipe for oil and gas field exploitation

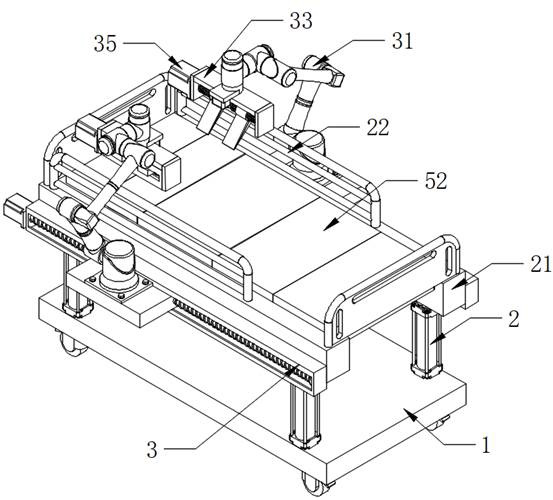

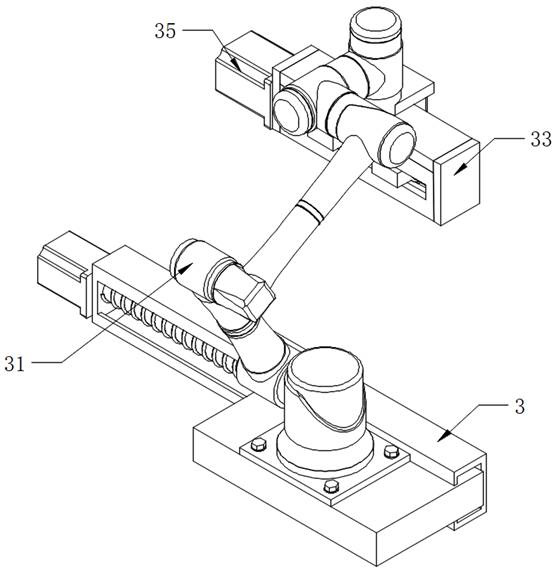

ActiveCN114453915AEasy constructionEasy to trip the drill pipeShaping toolsWelding/cutting auxillary devicesPistonCorrosion resistant

The invention relates to the technical field of oil pipe preparation devices for oil-gas field exploitation, in particular to a preparation device for a composite metal corrosion-resistant oil pipe for oil-gas field exploitation. According to the technical scheme, a power hydraulic cylinder is installed on the upper portion of a fixing support, and a metal sealing piston is installed in an inner cavity of the power hydraulic cylinder; a movable guide rail is installed on one side of a fixed support and provided with a movable support through rolling wheels, a stainless steel lining pipe is installed in an inner cavity of a base pipe, the front end of a metal sealing piston is connected with a sealing liquid conveying pipe, the other end of the sealing liquid conveying pipe is connected to a cooling water spraying head, and a pressurizing cone is installed on the outer side of the cooling water spraying head. A shaping stress application mold is mounted on the outer wall of the pressurizing cone, and the stainless steel lining pipe in the base pipe is extruded through the shaping stress application mold; the composite metal corrosion-resistant oil pipe has the beneficial effects that the composite metal corrosion-resistant oil pipe manufactured by the invention is the same as a traditional oil pipe in field application, engineering construction is facilitated, a drill rod is convenient to lift and drop, and the service life of the oil pipe is prolonged.

Owner:山东永利精工石油装备股份有限公司

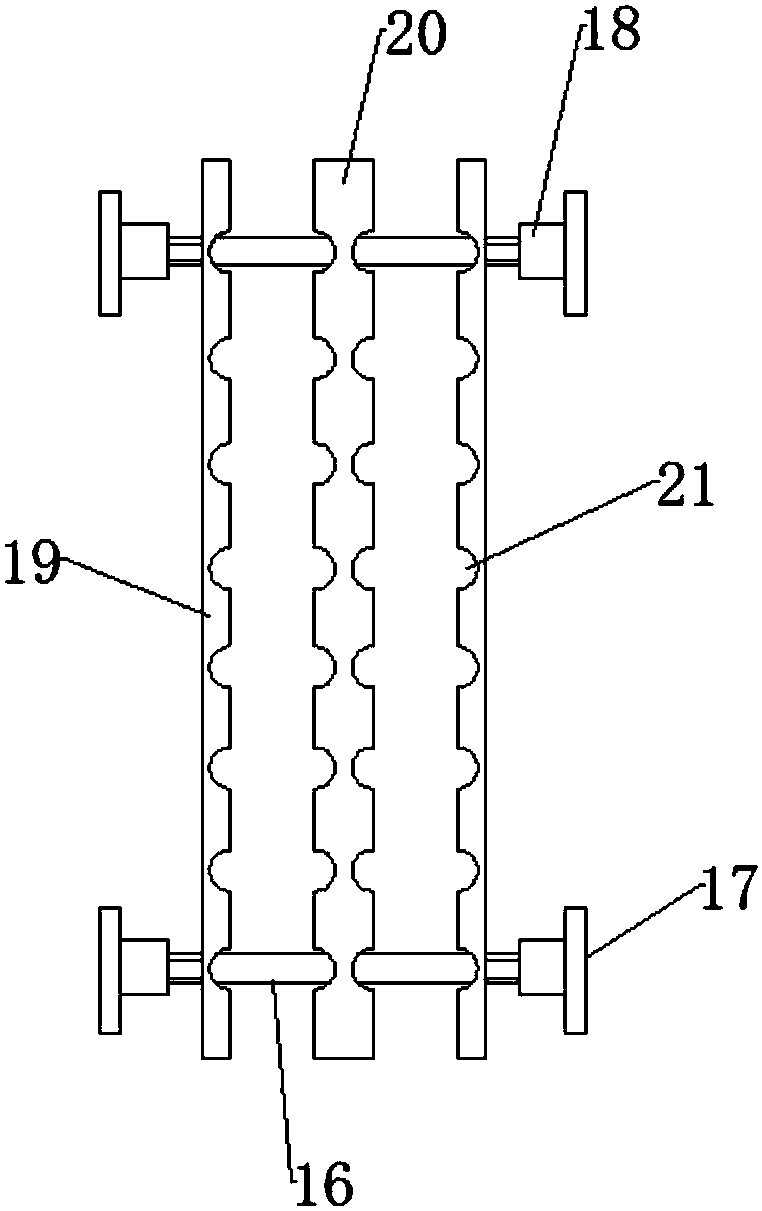

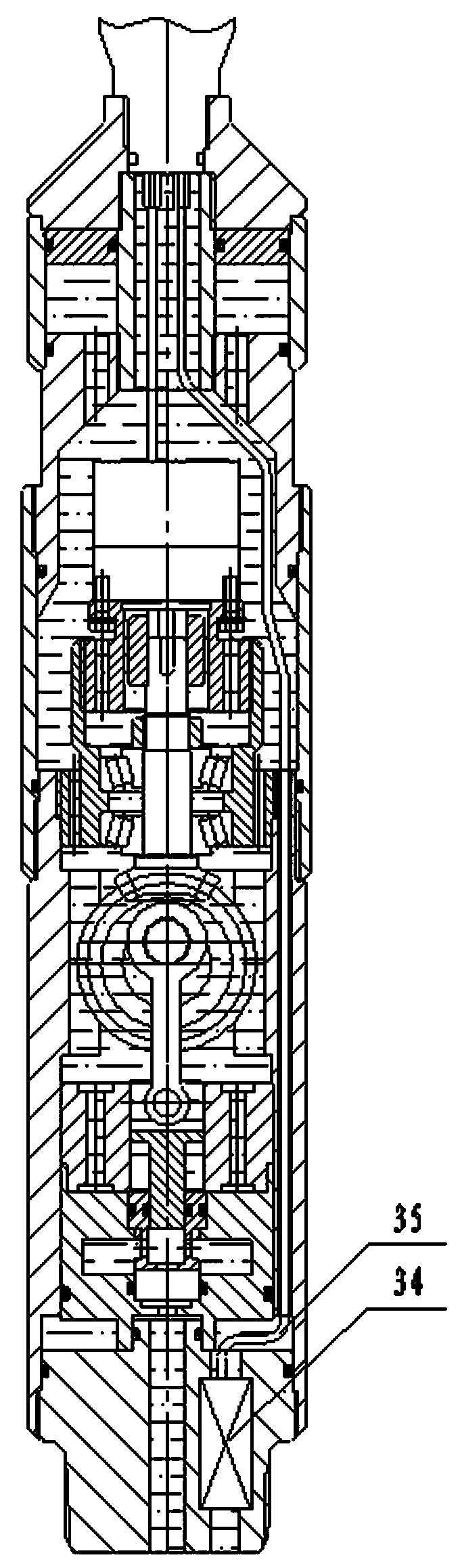

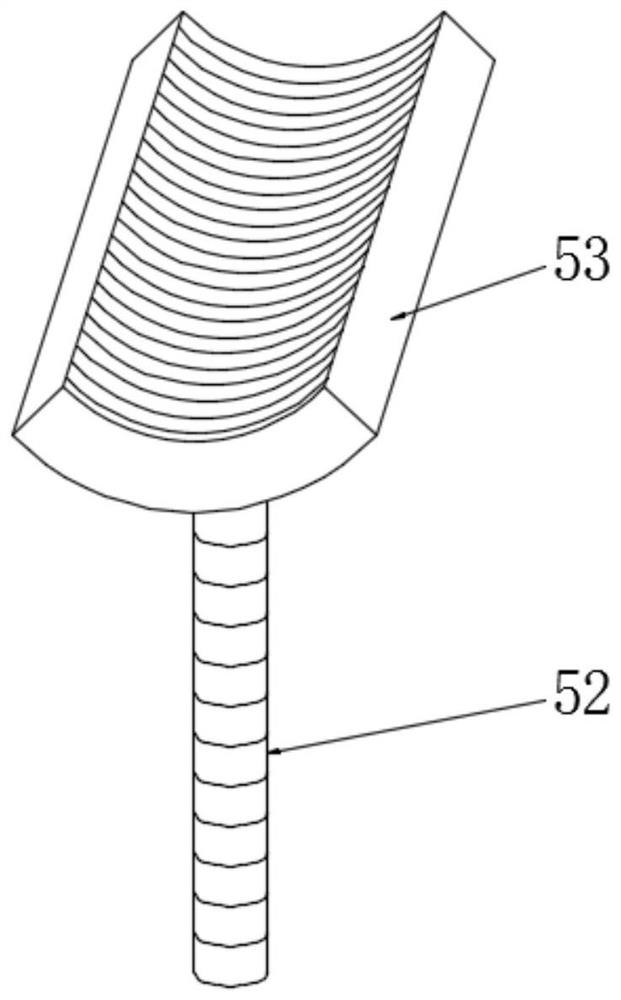

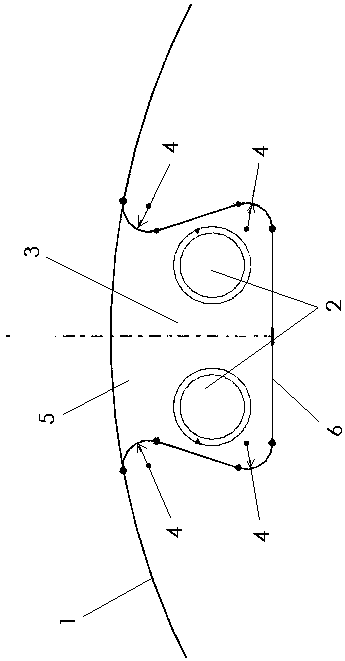

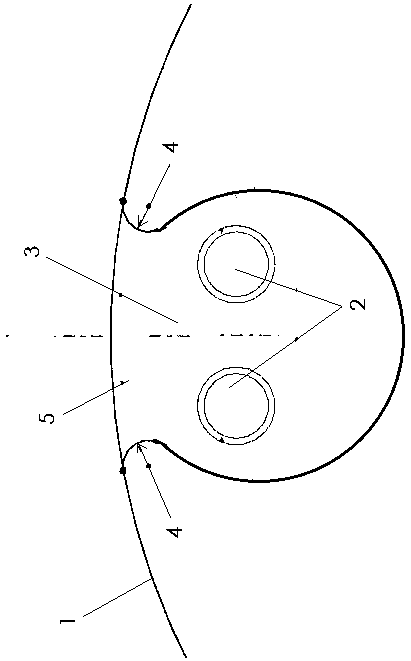

Damping centering guide structure for inclined shaft screw drill

InactiveCN106014286AExtended service lifeImprove oil recovery efficiencyDrilling rodsCleaning apparatusEngineeringBlock match

The invention discloses a damping centering guide structure for an inclined shaft screw drill. The damping centering guide structure for the inclined shaft screw drill comprises a screw drill axial shell and a connector body connected with the upper end of the screw drill axial shell, and a limiting groove is formed in the middle portion of the connector body. The connector body in the limiting groove is slidably sleeved with a nylon centering guide casing pipe. A plurality of buffering cavities are evenly formed in the outer side of the nylon centering guide casing pipe. Limiting cavities are formed in the two sides of each buffering cavity. Convex ribs are slidably arranged in the buffering cavities respectively. Limiting blocks matched with the limiting cavities are arranged on the two sides of one end of each convex rib respectively, and the other end of each convex rib extends out of the nylon centering guide casing pipe. A plurality of spring grooves are evenly formed in the inner side of each convex rib. Springs matched with the spring grooves are arranged in the spring grooves in the radial direction. The inner sides of the springs abut against the nylon centering guide casing pipe, the outer sides of the springs abut against the convex ribs, and the outer surfaces of the convex ribs are higher than the outer surface of the screw drill axial shell and the outer surface of the connector body.

Owner:JIANGSU PROVINCE JINFENG PETROLEUM MACHINERY MFG CO LTD

Slit type 00Cr9MoNi alloy steel sand prevention pipe

InactiveCN104213880AIncrease production capacityExtended service lifeFluid removalSand filterMaterials science

The invention discloses a slit type 00Cr9MoNi alloy steel sand prevention pipe. The slit type 00Cr9MoNi alloy steel sand prevention pipe comprises a sand prevention pipe body and sand filter slits; the slit type 00Cr9MoNi alloy steel sand prevention pipe is characterized in that the sand prevention pipe body is in a round pipe shape and is manufactured by adopting a 00Cr9MoNi alloy steel material, the sand prevention pipe body is provided with trapezoid sand filter slits in sections, the trapezoid sand filter slits have small outer openings and big inner openings which are cut by a laser gun from the outer circumference to the inner circumference, the distance between every two sections is 30-50mm, the width of the outer opening of each section of trapezoid sand filter slit which is 3-5m in length is 0.05-0.30 mm, the thickness of the outer opening of each section of trapezoid sand filter slit is 0.3-0.5mm, and two end parts of the sand prevention pipe body are provided with taper pipe male threads. The slit type 00Cr9MoNi alloy steel sand prevention pipe disclosed by the invention is manufactured by adopting the 00Cr9MoNi alloy steel material, corrosion resistance and scouring resistance are obtained, the service life is long, the well repairing period is prolonged, and the production time rate of an oil well is increased; the outer openings of the sand filter slits are small and thin, the inner openings of the sand filter slits are big, fine sand does not easily enter the sand filter slits, sand is unlikely to store, the blocking is unlikely to cause, the structure of the slit type 00Cr9MoNi alloy steel sand prevention pipe is simplified, the removal is convenient, the operation construction is convenient, and the sand prevention efficiency and the construction efficiency are increased.

Owner:DONGYING RUIZHI YOULIANG PETROLEUM EQUIP

Steam-propelling packer

A vapor impellent packer, which belongs to packer type of thick oil fill into underground well. This invention is advanced than the existing technologies, which compose of central tube, back bonnet, tube of rubber that are connected with upper adapter by buckle, and mover, expander, piston, spacing hat, spring, location-holder, airtight packing and protective holder. When switch-in the underground well filler pipe, rubber tube can glue on the well wall by the mover and expander which achieve the hermetization and sealed-off. The technology can decrease the accident of underground well, and improve the successful ratio and effect of seat-seal.

Owner:潘昌德

Multifunctional neurosurgical intensive care nursing bed

The invention discloses a multifunctional neurosurgical intensive care nursing bed. The bed comprises a bed body. The bed body comprises a front bed body and a rear bed body. The bottoms of the frontbed body and the rear bed body are both provided with supporting legs, and the bottoms of the supporting legs are provided with trundles. An insertion connection plate is arranged at the connection end of the front bed body and the rear bed body, an insertion connection slot is formed in the connection end of the rear bed body and the front bed body, and the insertion connection plate can be inserted into the insertion connection slot and move back and forth in the insertion and connection slot. The bottom of the rear bed body is provided with a vital sign sensor. The top of the front bed bodyis provided with an adjusting plate, one end of the adjusting plate is hinged to the rear portion of the front bed body, and a height adjusting device is arranged between the adjusting plate and theupper surface of the front bed body. The front bed body and the rear bed body are connected through the insertion connection plate, the insertion connection plate can slide in the insertion connectionslot, and the front bed body and the rear bed body can be connected together to facilitate movement and transfer. The distance between the front bed body and the rear bed body is adjustable, and thebed is convenient to move and use.

Owner:张淑霞

Liftable mattress

InactiveCN106263806AReduce work intensityReasonable structureStuffed mattressesSpring mattressesAgricultural engineeringSoft materials

Owner:安徽柒柒塑业有限公司

Auxiliary rising and lying device for nurse in cardiac intensive care unit and using method of auxiliary rising and lying device

The invention belongs to the technical field of intensive care units, and particularly relates to an auxiliary rising and lying device for a cardiac intensive care unit nurse and a using method of the auxiliary rising and lying device. The auxiliary rising and lying device comprises a movable base and further comprises a turning-over device, a rising and lying device body and an auxiliary device, and the turning-over device is located on the upper surface of the movable base and conducts automatic turning-over work on a patient needing to be turned over. According to the auxiliary rising and lying device for the nurse in the cardiac intensive care unit and the using method of the auxiliary rising and lying device, the rising and lying device is arranged, a patient on a bed board is automatically subjected to rising and lying work, a rising and lying electric push rod pushes a rack, so that a rising and lying gear rotates, a connecting block on a supporting shaft is driven to deflect, a head supporting plate and a back supporting plate in a supporting component on the connecting block can deflect at the end hinged to a hip supporting plate, the upper body of the patient is lifted upwards, the patient automatically completes rising and lying work, and therefore the patient can be rapidly and stably assisted to complete rising and lying work, and shaking caused to the patient is reduced.

Owner:THE 7TH PEOPLES HOSPITAL OF ZHENGZHOU

Processing tooling for ceramic cup production line

The invention discloses a processing tooling for a ceramic cup production line. The processing tooling comprises a supporting platform, two sides of the upper portion of the supporting platform are fixedly connected with supporting plates, the upper portion of each supporting plate is fixedly connected with a guide rail, a supporting frame is arranged on the guide rails, the supporting frame comprises supporting vertical beams, one side of each supporting vertical beam is provided with a sliding rail, the bottom end of each supporting vertical beam is movably connected with a sliding wheel, each sliding wheel is slidably connected with the corresponding guide rail, the outer side of the lower end of each supporting vertical beam is fixedly provided with a driving motor, the upper portionsof the supporting vertical beams are fixedly connected with a beam, the upper portion of the beam is fixedly provided with an electric cylinder, the output end at the lower end of the electric cylinder is fixedly connected with a lifting plate, the inner side of each supporting vertical beam is fixedly connected with a guide column, the upper surface of the supporting platform is fixedly connectedwith rails, the upper portions of the rails are slidably connected with moving fixtures, and two sides of each rail are fixedly connected with fixed plates. The processing tooling for the ceramic cupproduction line is reasonable in design, the cups are conveniently clamped, and the cups are conveniently processed.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

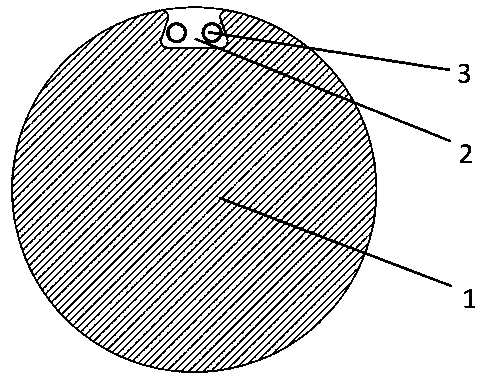

Wear-resistant oil drill pipe

InactiveCN106150398AExtended service lifeReduce shock absorptionDrilling rodsDrilling casingsWear resistantPetroleum engineering

The invention discloses a wear-resistant oil drill pipe long in service life. The oil drill pipe comprises a drill pipe body. An installation groove is formed in the drill pipe body and internally provided with a bearing inner ring through a pressing block and a pressing ring. A plurality of spring grooves are evenly formed in the inner side of the bearing inner ring. Springs matched with the spring grooves are arranged in the spring grooves in the radial direction. The inner sides of the springs abut against the drill pipe body. The outer sides of the springs abut against the bearing inner ring. A bearing outer ring is rotationally arranged outside the bearing inner ring through a rotor. A wear-resistant layer is arranged outside the bearing outer ring. The oil drill pipe has the advantages that when the drill pipe is lifted up and put down in a horizontal well, an inclined well and a measure well, if a sleeve wall is hit, the bearing inner ring with the springs can bear force and automatically retract, buffering and shock absorbing can be effectively achieved, and the drill pipe can be conveniently lifted up and put down and can be protected; meanwhile, the bearing outer ring can drive the wear-resistant layer to continuously rotate along the bearing inner ring under the effect of the rotor after bearing force, the wear resistant effect is good, and the drill pipe is long in service life.

Owner:JIANGSU PROVINCE JINFENG PETROLEUM MACHINERY MFG CO LTD

Special medical bed for new coronary pneumonia treatment

InactiveCN111821122AIncrease the areaAchieving Width AdjustmentNursing bedsMedical equipmentEngineering

The invention discloses a special medical bed for new coronary pneumonia treatment, and relates to the technical field of medical equipment. The special medical bed comprises a bed body, wherein folding plates are rotationally mounted on two sides of the bed body; expansion plates are embedded into the front side and the rear side of the bed body; a driving component is arranged inside the bed body; and the driving component is used for driving the two expansion plates to stretch out or retract at the same time. The special medical bed is reasonable in structure and simple to operate, due to adoption of the expansion plates, the area of the medical bed can be increased, meanwhile a certain protection effect can be achieved, the comfort and the security of operators can be improved, the medical bed can be folded when being not used, the space occupation rate can be reduced, the practicability can be improved, the problems that a conventional medical bed is fixed in width, relatively poor in comfort, relatively large in size and large in space occupation rate can be solved, due to adoption of the driving component, stretching and retraction actions of the expansion plates can be achieved, and width adjustment of the medical bed can be achieved.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

Multifunctional medical bed with pedestal pan

InactiveCN111035514AEasy to get up and downSolving the Meals in Bed ProblemCleaning devicesBedpansGear wheelSurgery

The invention discloses a multifunctional medical bed with a pedestal pan. Wheels are fixedly arranged at the lower ends of L-shaped fixed stand columns, the left and right L-shaped fixed stand columns are fixedly connected through a track plate, a supporting block is arranged in the upper end wall in the track plate, a first gear cavity is formed in the supporting block, a threaded sleeve is rotationally arranged in the first gear cavity, a first gear is fixedly arranged on the threaded sleeve, and the right end of the first gear is engaged with a second gear. According to the invention, lifting of a backrest and change of leg positions are realized electrically, patients can get up and lie down conveniently and are assisted in loosening sclerotin, promoting blood circulation and removingblood stasis, the rotary lifting is arranged to assist the patient in standing, in addition, a slidable small table plate is arranged to solve the problem of dining on the bed of the patient, the pedestal pan which enables the patient to defecate at any time and can reduce the discomfort of defecation of the patient is arranged, and therefore convenience is brought to the patient who does not move properly.

Owner:GUANGZHOU HAOJIA MEDICAL EQUIP CO LTD

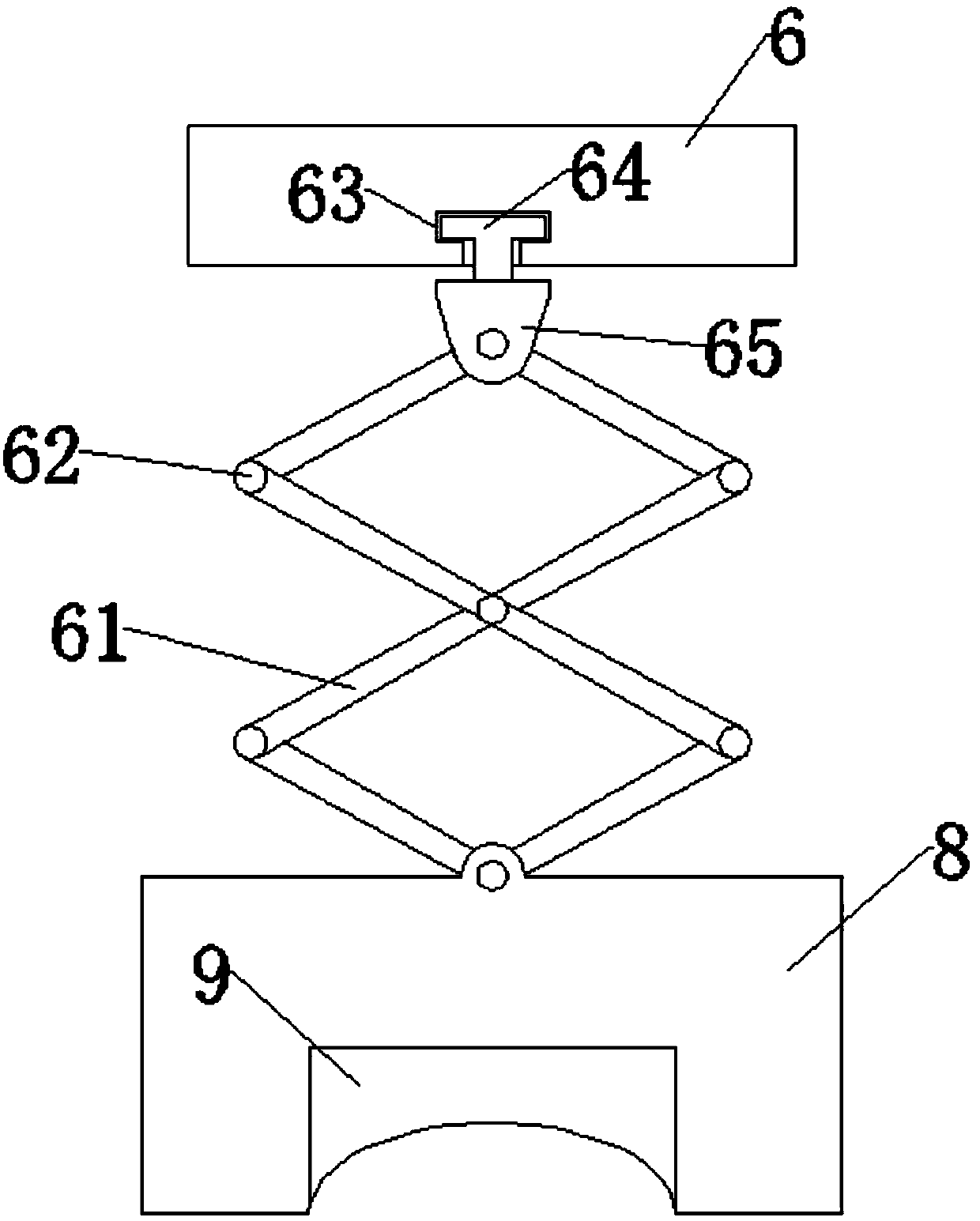

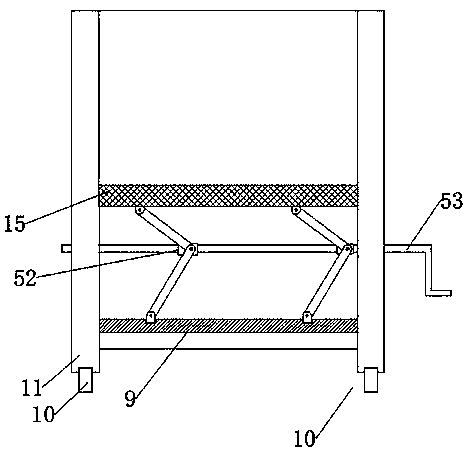

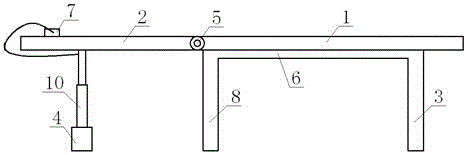

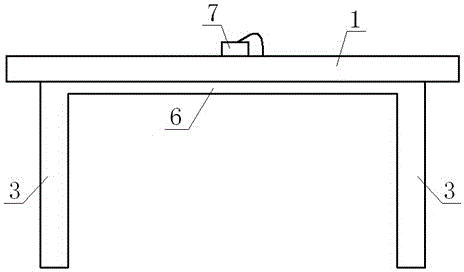

Hospital bed for patient to get up and lie down and with simple structure

The invention discloses a hospital bed for a patient to get up and lie down and with a simple structure. The hospital bed comprises a fixed bed board and a movable bed board, wherein the fixed bed board is connected with the movable bed board by a shaft pin; a supporting device is arranged under the fixed bed board; a jacking device is arranged under the movable bed board; a sliding groove matched with the jacking device is arranged at the bottom part of the movable bed board; the jacking device is connected with the movable bed board by the sliding groove; the supporting device comprises two front bed legs, two rear bed legs and horizontal supporting rods; the two front bed legs are arranged at the end parts under the fixed bed board in parallel; the two rear bed legs are arranged under the shaft pin in parallel; the horizontal supporting rods are respectively connected with the top parts of the front bed legs and the top parts of the rear bed legs to form a whole body. The hospital bed disclosed by the invention has the beneficial effects that the structure is simple, convenience is brought for the patient to get up and lie down, and the operation is convenient.

Owner:成都米娅天歌生物科技有限公司

High-energy penetrating moxibustion instrument for human meridians and collaterals

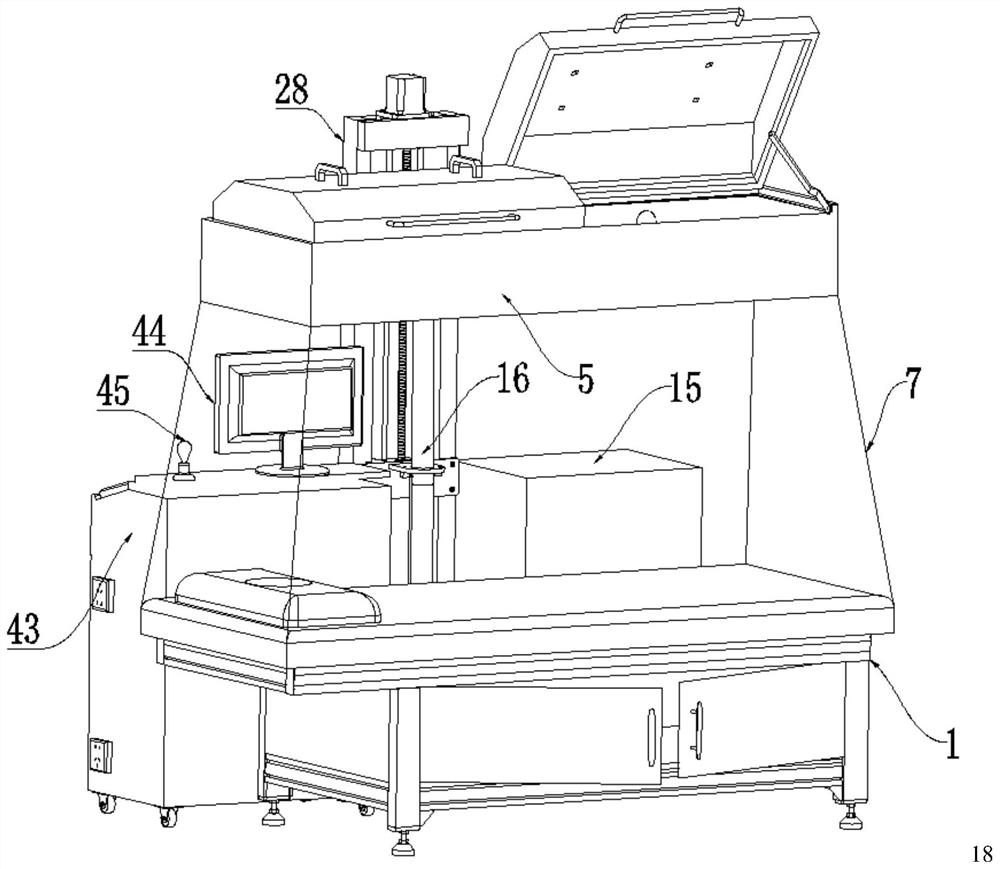

PendingCN113081812AImprove comfortBig spaceDevices for heating/cooling reflex pointsDirt cleaningPhysicsElectrical control

The invention discloses a high-energy penetrating moxibustion instrument for human meridians and collaterals. The instrument comprises a moxibustion bed assembly, an energy chamber, a lifting device, a smoke purification device and an electric control box; a positioning plate is installed in the energy chamber box body, a moxa cone box is installed on the positioning plate, and smoke exhaust holes are formed in the left side and the right side of the inner wall of the rear side of the energy chamber box body; a smoke exhaust hole in the energy chamber is used for being connected with the smoke purification device, and the smoke purification device comprises a smoke conveying device and a smoke purifier; and the smoke conveying device comprises an upper smoke exhaust pipe, a middle smoke exhaust pipe and a lower smoke exhaust pipe, the upper smoke exhaust pipe is connected with the energy chamber, the other end of the upper smoke exhaust pipe is sequentially connected with the middle smoke exhaust pipe and the lower smoke exhaust pipe, a smoke inlet pipe is transversely installed on one side of the lower portion of the lower smoke exhaust pipe, the smoke inlet pipe is connected with the smoke purifier, and the lifting device is connected with the upper smoke exhaust pipe.

Owner:浙江云灸人间生物科技有限公司

Underground hydraulic pump

PendingCN110374533AEasy to get up and downAccelerateBorehole/well accessoriesPistonAgricultural engineering

The invention discloses an underground hydraulic pump. The upper end of an upper connector center hole is inserted in a bridle, and the lower end of the upper connector center hole is inserted into acenter pipe. An oil cylinder is installed between the connecting sleeve and an upper connector. A piston is arranged on the center pipe in a sleeving manner. The upper end of an upper outer sleeve isarranged at the lower end of the connecting sleeve in a sleeving manner, and the lower end of the upper outer sleeve is inserted in a lower outer sleeve. The upper end of the lower outer sleeve is provided with a lower inner sleeve. The upper end of the lower inner sleeve is provided with an upper inner sleeve. A small bevel gear shaft is fixedly installed in inner rings of two first bearings, andthe small bevel gear shaft is sleeved with a nut. The upper end of the upper inner sleeve is in bolt connection with a planetary gearbox and a motor, and the outer side of the lower outer sleeve is in threaded connection with a bearing end cover. A second bearing, a gear shaft, a large bevel gear and a crank are arranged, and a bevel gear transmission mechanism is composed of the large bevel gearand the small bevel gear shaft. A plunger outer sleeve and a tee joint are installed in the lower outer sleeve, and the lower end of the lower outer sleeve is in threaded connection with a lower connector. The lower end of the underground hydraulic pump is connected with a hydraulic releasing type packer, the hydraulic releasing type packer can be screwed off conveniently, the speed is high, andno use risk exists.

Owner:FUXIN CITY GASOLINEEUM TOOL FACTORY

Sickbed with rising-lying and turnover function

PendingCN106309046ASmooth rotationRotation is convenient for patients to control according to their own needsNursing bedsBed loadEngineering

The invention discloses a sickbed with a rising-lying and turnover function. The sickbed comprises a fixed bed board, a rising-lying bed board, turnover bed boards a and turnover bed boards b, wherein two sides of the fixed bed board in the length direction are respectively connected with the turnover bed boards a by virtue of shaft pins b, two sides of the rising-lying bed board in the length direction are respectively connected with the turnover bed boards b by virtue of the shaft pins b, and the side surface of the fixed bed board in the width direction is connected with the side surface of the rising-lying bed board in the width direction by virtue of a shaft pin a; and four bed legs are arranged below the fixed bed board, and a jacking apparatus is respectively arranged below the rising-lying bed board, the turnover bed boards a and the turnover bed boards b. The sickbed has the beneficial effects that the rising and lying of a patient are facilitated, the patient is also convenient to turn over, the use is convenient, and the operation is simple.

Owner:成都米娅天歌生物科技有限公司

A device for preparing composite metal corrosion-resistant tubing for oil and gas field development

ActiveCN114453915BExtended service lifeEasy to get up and downShaping toolsWelding/cutting auxillary devicesHydraulic cylinderThermodynamics

The invention relates to the technical field of an oil pipe preparation device for oil and gas field development, in particular to a preparation device for a composite metal corrosion-resistant oil pipe for oil and gas field development. The technical solution is: a power hydraulic cylinder is installed on the upper part of the fixed bracket, and a metal sealing piston is installed in the inner cavity of the power fluid cylinder; Install the stainless steel lining pipe, the front end of the metal sealing piston is connected to the sealed infusion tube, the other end of the sealed infusion tube is connected to the cooling water spray head, and the pressurized cone is installed on the outside of the cooling water spray head, and the outer wall of the pressurized cone is installed and shaped The booster die squeezes the stainless steel liner in the base pipe through the stereotyped booster die; the beneficial effect is that the composite metal corrosion-resistant oil pipe made by the present invention is the same as the traditional oil pipe in field application, which is convenient for engineering construction and convenient starting. Lower the drill pipe and prolong the service life of the tubing.

Owner:山东永利精工石油装备股份有限公司

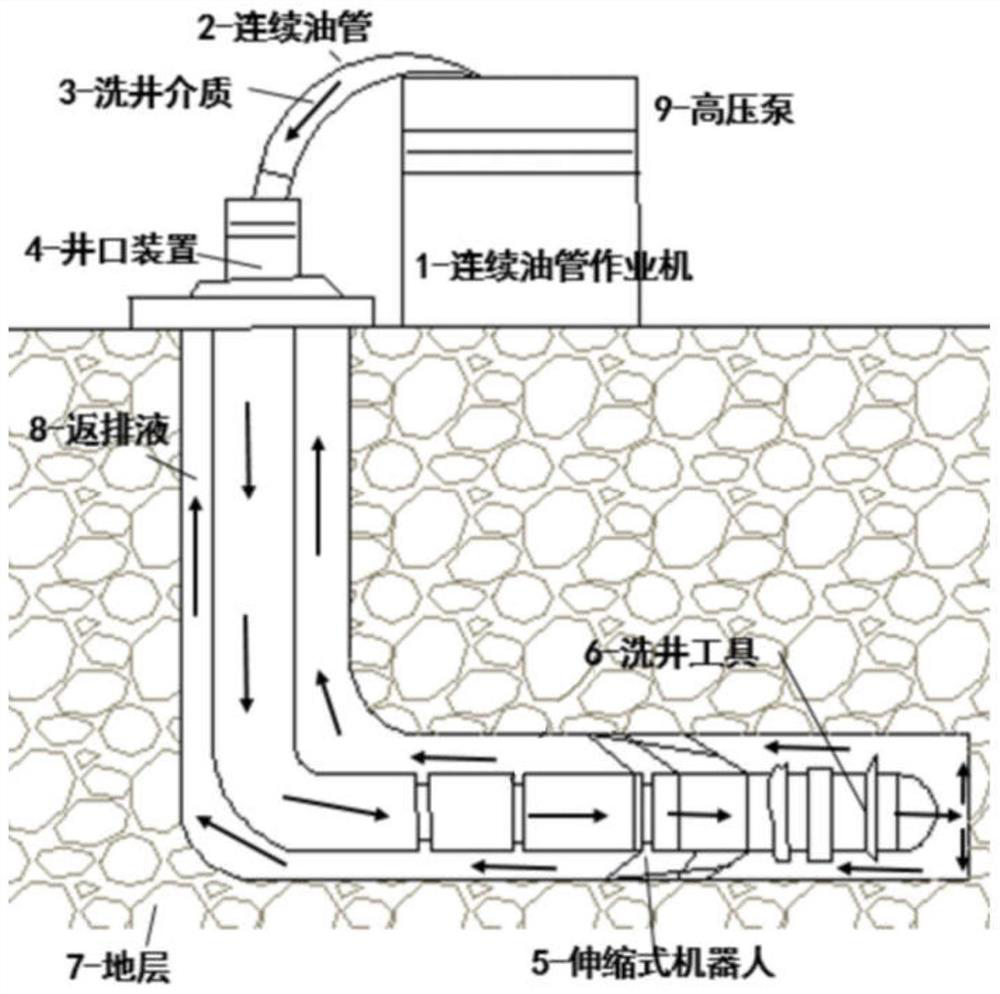

Closed-loop well washing method based on coiled tubing and telescopic robot

PendingCN113482556AReduce operating costsSave money and material resourcesFlushingHorizontal wellsControl engineering

The invention discloses a closed-loop well washing method based on a coiled tubing and a telescopic robot. The closed-loop well washing method comprises the following steps that the two ends of the coiled tubing are connected with a coiled tubing operation machine and a downhole tool respectively, and the downhole tool comprises the telescopic robot and a well washing tool which are connected; the coiled tubing operation machine is started, and the coiled tubing is lowered; a well washing medium is pumped into the coiled tubing at high pressure, mechanical-electric-hydraulic three-phase coupling is carried out with the telescopic robot, traction force is generated, and the coiled tubing reaches a well bottom working section in combination with ground power; meanwhile, the well washing medium continues to flow along the coiled tubing and is injected out of the downhole tool, and sand washing and well washing are conducted on the well bottom working section; the medium after well washing flows back to the ground along with an annulus between a well wall and the coiled tubing; and the closed-loop well washing operation is completed by continuously pumping the well washing medium and repeatedly washing the well. The closed-loop well washing method can solve the problems of deflection section oil pipe buckling and horizontal section blocking during horizontal well washing through the coiled tubing, the tool is lowered in place, and the operation efficiency is improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Raw material batching device for dust suppressant production

PendingCN112871013AEasy to adjustEasy loading and unloadingTransportation and packagingRotary stirring mixersEngineeringMechanical engineering

A disclosed raw material batching device for dust suppressant production comprises a base, a shaft barrel, a supporting shaft and a carrying plate, an open groove is formed in one side edge of the base and penetrates the middle, a plurality of rotating rollers are rotationally installed between two opposite inner groove walls of the open groove, and the plurality of rotating rollers are consistent in specification and are distributed in an equidistant linear array mode. The shaft barrel is vertically and fixedly installed at the top end of the base, a shaft cavity is formed in the top end of the shaft barrel, a shaft hole penetrating through the outer barrel wall of the shaft barrel is formed in an upper cavity opening of the shaft cavity, a supporting shaft matched with the shaft cavity is movably sucked into the shaft cavity, a carrying plate is vertically and fixedly installed at the top end of the supporting shaft, and an extrusion positioning mechanism is fixedly installed on the outer barrel wall of the upper barrel opening of the shaft barrel. The extrusion positioning mechanism comprises a fixing block, and the fixing block is fixedly installed on the outer barrel wall of an upper barrel opening of the shaft barrel. The dust suppressant production raw material batching device has the beneficial effects that feeding and discharging are convenient, and the height of a stirring paddle is convenient to adjust.

Owner:上海鼎臣环保科技有限公司

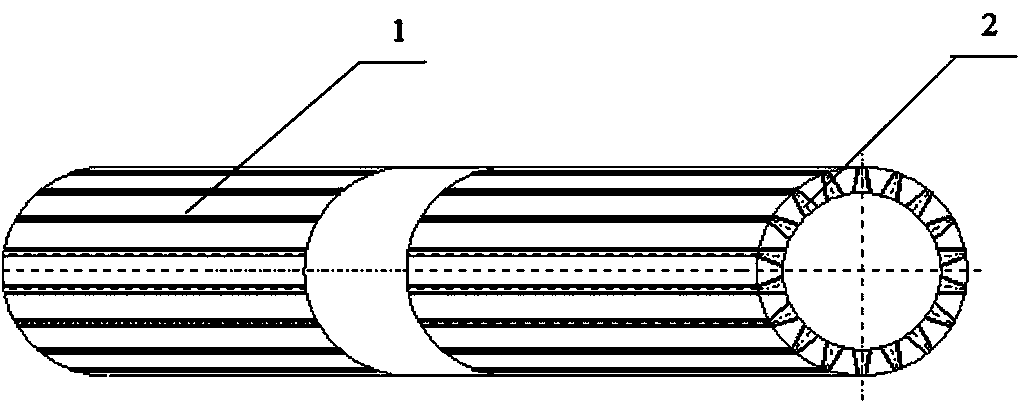

Intelligent well testing steel wire for distributive optical fiber detection

The invention discloses an intelligent well testing wire for a distributive optical fiber detection. The intelligent well testing wire comprises a steel wire body, an optical fiber unit and sealing adhesives; the steel wire body is a steel wire provided with a groove; the optical fiber unit is located in the groove of the steel wire; the groove is filled with the sealing adhesives; the optical fiber unit is fixed in the groove by the sealing adhesives; and the internal maximum width of the groove of the steel wire body is larger than the width of an opening. The intelligent well testing wire has the beneficial effects that under-well data can be acquired in real time by the intelligent well testing steel wire; the intelligent well testing wire can not only be used for descending length correction of the steel wire, but also can be used for acquiring under-well tension, well deviation and shocking data. The optical fiber unit can used for transmitting data in real time, so that duplex communication is realized; under-well pressure, flow and other well testing data are transmitted in real time; the intelligent well testing wire can also serve as a distributive sensor for sound wave / vibration and temperature; the full-thread environment parameters of the steel wire are monitored; a conventional well testing instrument is replaced, and distributive physical parameters which are difficult to monitor in the prior art are provided; and the purchasing cost of the well testing instrument and equipment is greatly lowered.

Owner:山东希尔电缆有限公司

Preset production fluid section plane test method of mechanical mining horizontal well and special shaft mouth test apparatus

ActiveCN101403291BEasy to get up and downSo as not to damageSurveyConstructionsSection planeTubing hanger

The invention relates to a mechanical recovery horizontal well preset produced fluid profile testing method and a special wellhead testing device thereof, mainly aiming at solving the problem of the downhole testing of a mechanical recovery horizontal well. The invention is characterized in that: the special wellhead testing device comprises an eccentric type tubing hanger body connected with a tubing string, wherein, the side wall of the tubing hanger body is divided into a body and splits which are completely matched with each other, and the splits are fixed on a locking arm which is fixed on the body though bolts; and a corresponding matched cable penetrating a channel is arranged at the splitting seam of the body and the splits, the channel is internally provided with a cable gasket, a spacer and a pressing cap. By being matched with a special wellhead support, under the condition that a testing cable and a tester are pre-arranged in the horizontal well to test a target layer, an oil pipe does not touch the cable during the up and down process of the oil pipe. The method and the special wellhead testing device can realize the produced fluid profile testing of the mechanical recovery horizontal well, and ensure the accuracy of normal testing and data of the mechanical recovery horizontal well with simple and reliable operation method.

Owner:DAQING OILFIELD CO LTD +1

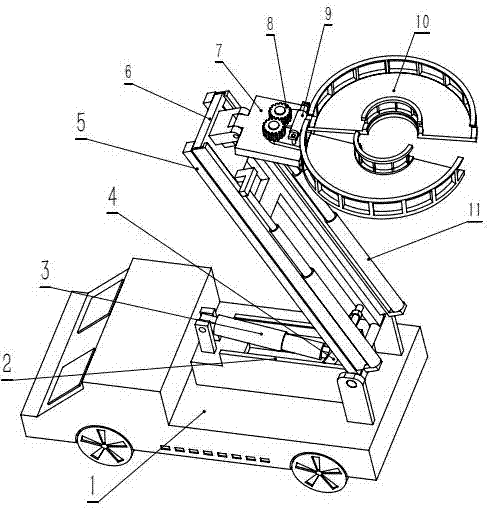

An all-round electric work vehicle

The invention provides an all-round power working vehicle which comprises an automobile chassis, an erection sliding table and an erection hydraulic cylinder, wherein the erection sliding table is arranged at the upper part of the automobile chassis; roller slots are formed in both sides of the upper part of the erection sliding table; a first bracket is arranged at a position, close to an automobile cab, at the front part of the erection sliding table. Two semicircular split type working tables of the all-round power working vehicle form an integrally circular working table after being combined, and a small circle in the middle can accommodate a pole; a worker can do activities without any dead corner around the pole by 360 degrees, and the working range of the worker is expanded.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com