Closed-loop well washing method based on coiled tubing and telescopic robot

A telescopic and robotic technology, which is applied in wellbore flushing, earthwork drilling, wellbore/well components, etc., can solve the problem of incomplete running of downhole tools, time-consuming and labor-intensive washing of drill pipes, and insufficient power at the working end, etc. problems, achieve high operating efficiency, solve buckling and horizontal section blocking, and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the technical features in the embodiments can be combined with each other. It should be noted that, unless otherwise specified, all technical and scientific terms used in this application have the same meaning as commonly understood by those of ordinary skill in the art to which this application belongs. The disclosure of the present invention uses "comprises" or "comprises" and other similar words to mean that the elements or objects appearing before the words include the elements or objects listed after the words and their equivalents, without excluding other elements or objects.

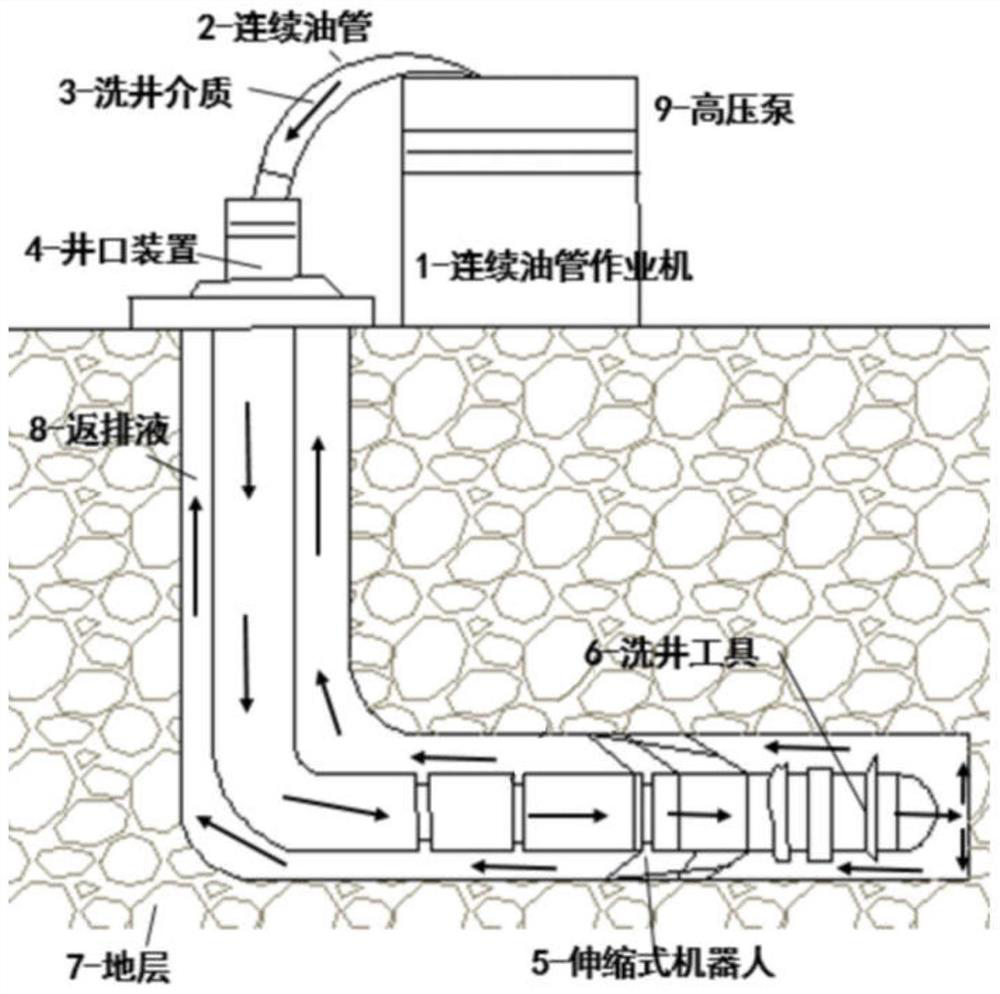

[0028] Such as figure 1 As shown, the present invention provides a kind of closed-loop flushing method based on coiled tubing and telescopic robot, comprising the following st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com