A device for preparing composite metal corrosion-resistant tubing for oil and gas field development

A composite metal and preparation device technology, applied in metal processing equipment, metal processing, auxiliary devices, etc., can solve problems such as production tubing corrosion, oil production plant loss, tubing corrosion and perforation, etc., to facilitate engineering construction and tripping of drill pipes , The effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

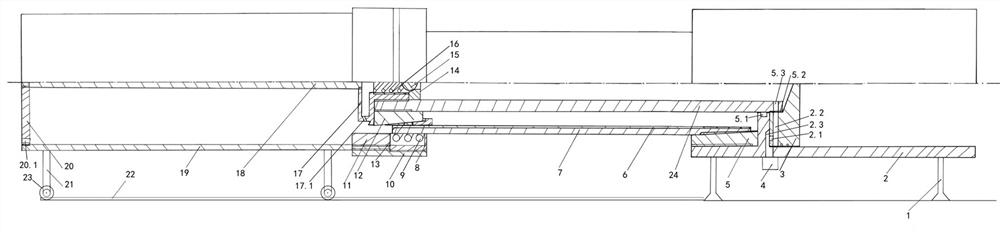

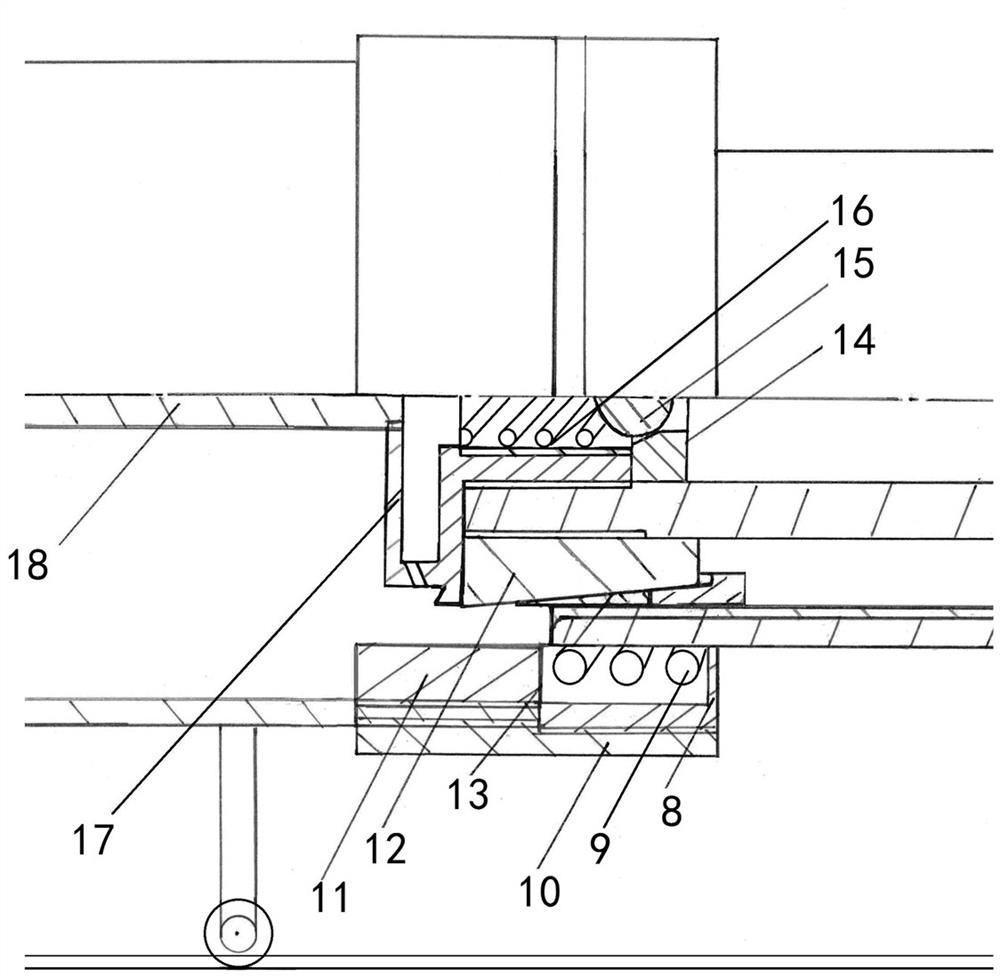

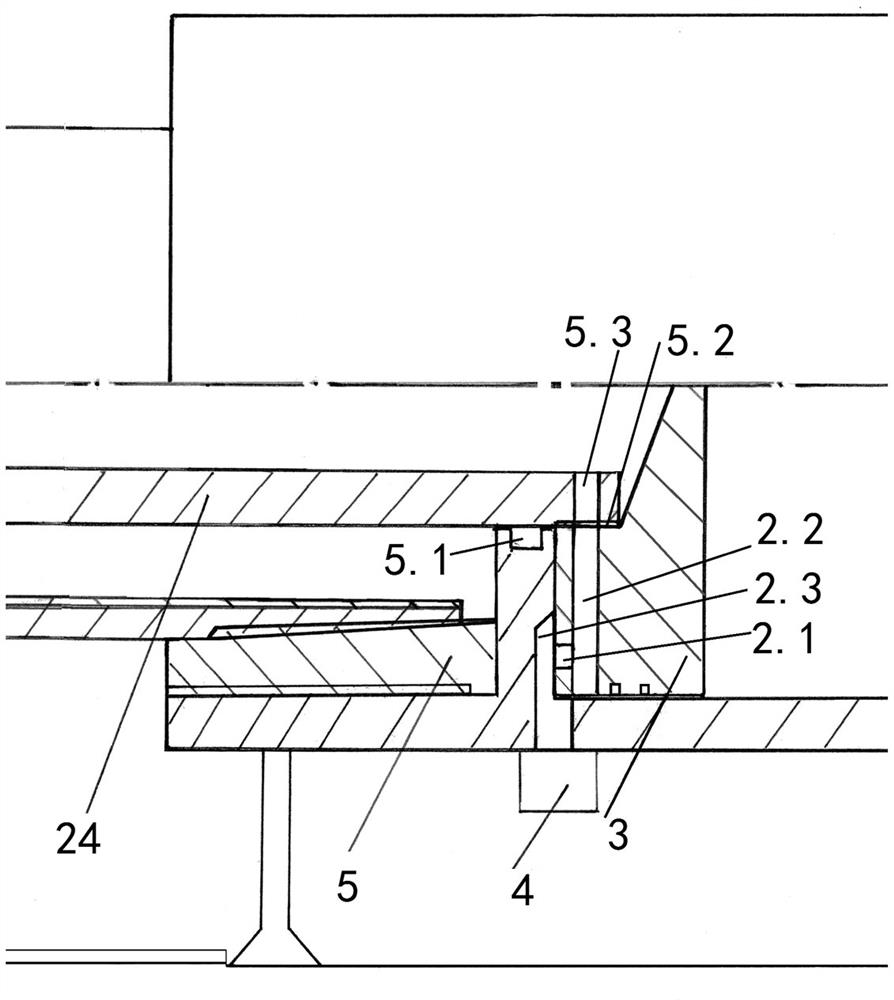

[0024] Example 1, refer to figure 1 , an oil and gas field development device mentioned in the present invention adopts a composite metal corrosion-resistant oil pipe preparation device, including a fixed bracket 1, a power hydraulic cylinder 2, a metal sealing piston 3, a movable bracket 21, a movable guide rail 22, and a rolling wheel 23. The fixed bracket A power hydraulic cylinder 2 is installed on the upper part of the 1, and a metal sealing piston 3 is installed in the inner cavity of the power hydraulic cylinder 2; a moving guide rail 22 is installed on one side of the fixed bracket 1, and the moving guide rail 22 installs the moving support 21 through the rolling wheel 23, wherein all the The front end of the power hydraulic cylinder 2 is provided with an oil pipe connection head 5, the outer wall of the oil pipe connection head 5 is fixed on a set of fixed brackets 1, the inner wall of the oil pipe connection head 5 is connected to the base pipe 7 by threads, and the i...

Embodiment 2

[0039] Example 2, a kind of oil and gas field development mentioned in the present invention adopts a composite metal corrosion-resistant oil pipe preparation device, including a fixed bracket 1, a power hydraulic cylinder 2, a metal sealing piston 3, a movable bracket 21, a movable guide rail 22, and a rolling wheel 23. A power hydraulic cylinder 2 is installed on the upper part of the fixed bracket 1, and a metal sealing piston 3 is installed in the inner cavity of the power hydraulic cylinder 2; a moving guide rail 22 is installed on one side of the fixed support 1, and the moving guide rail 22 installs the moving support 21 through the rolling wheel 23, The front end of the power cylinder 2 is provided with an oil pipe connector 5, the outer wall of the oil pipe connector 5 is fixed on a set of fixed brackets 1, the inner wall of the oil pipe connector 5 is connected to the base pipe 7 through threads, and the inner wall of the base pipe 7 A stainless steel lining pipe 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com