Blowout-prevention tool string of belt pressure energy storage well repairing machine

A technology for blowout prevention tools and workover rigs, which is applied in wellbore/well components, earthwork drilling, sealing/package, etc. It can solve problems such as difficulty in installation and positioning of blowout prevention tool strings, and difficulty in replacing blowout preventer seals , to achieve the effect of convenient maintenance operation, convenient operation and reasonable matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further disclose the technical solution of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

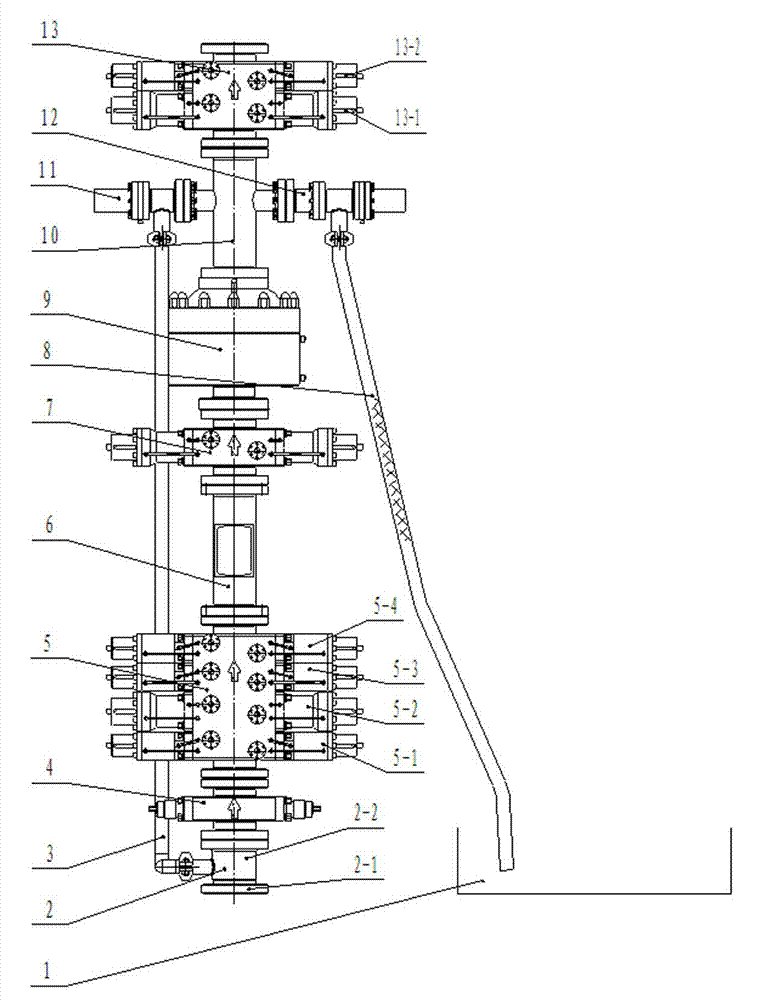

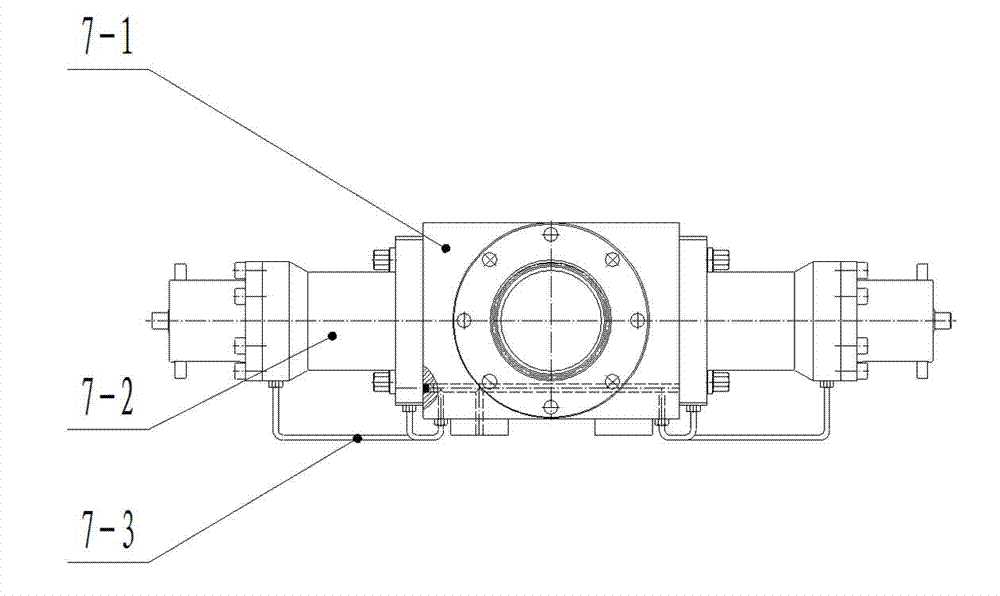

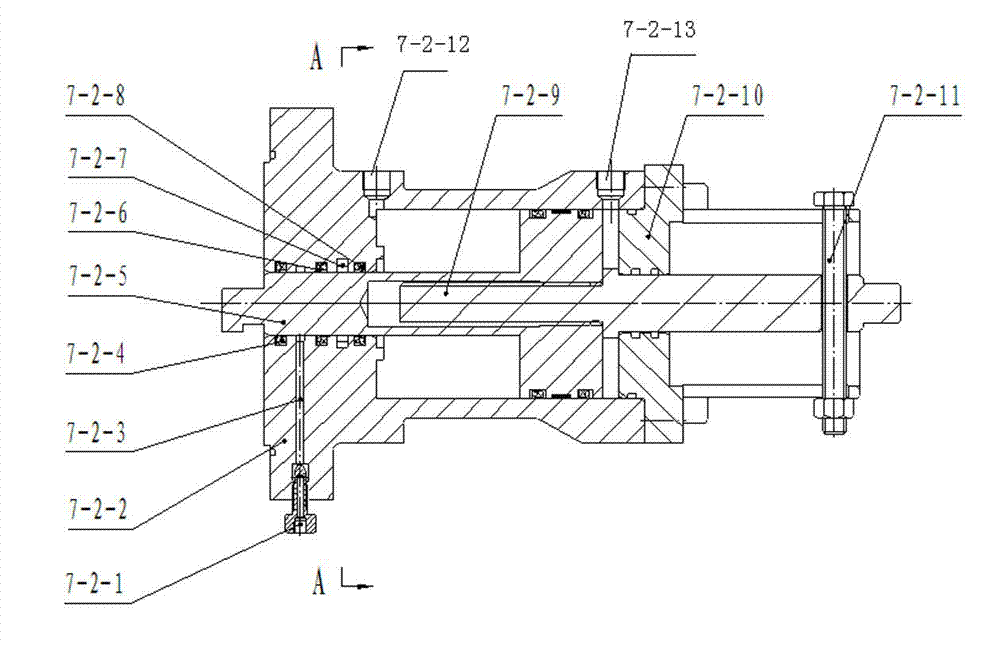

[0017] A blowout preventer tool string for a pressurized energy storage workover rig includes a four-ram blowout preventer 5, a shear blowout preventer 7, a balance device 11 and a double ram blowout preventer 13, and the tool string is connected sequentially from bottom to top Rotary mechanism 2, manual centralizer 4, four-ram blowout preventer 5, connecting platform nipple 6, shearing blowout preventer 7, annular blowout preventer 9, raising nipple 10, balancing device 11, venting device 12 and Double ram blowout preventer 13, one end of the balance pipeline 3 is connected to the balance device 11, and the other end is connected to the rotating mechanism 2; the four ram blowout preventer 5, the shear blowout preventer 7 and the double ram blowout preventer 13 are all provided There is a secondary seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com