Intelligent well testing steel wire for distributive optical fiber detection

A distributed optical fiber and steel wire technology, applied in the directions of measurement, measurement device, wellbore/well components, etc., can solve the problems of optical fiber sensing sensitivity and measurement accuracy, inaccurate steel wire depth calibration, complicated manufacturing process, etc., to avoid problems such as The effect of blind operation and construction, reducing procurement costs and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Accompanying drawing is a kind of specific embodiment of the present invention.

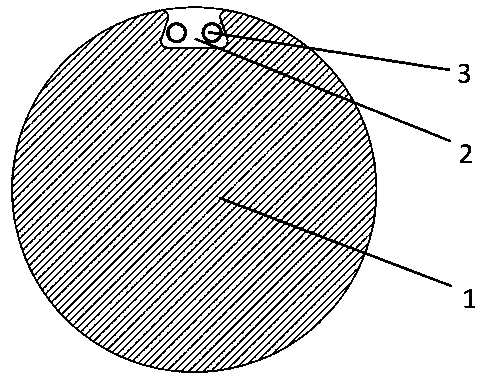

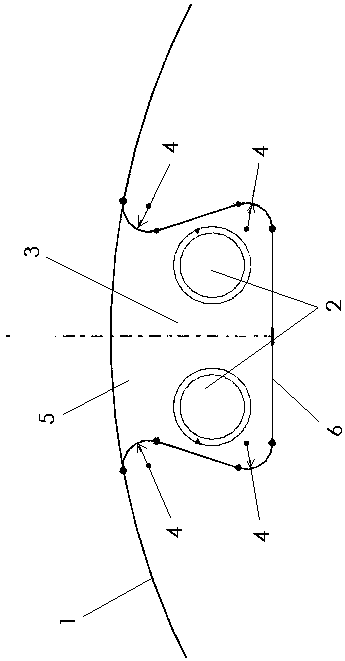

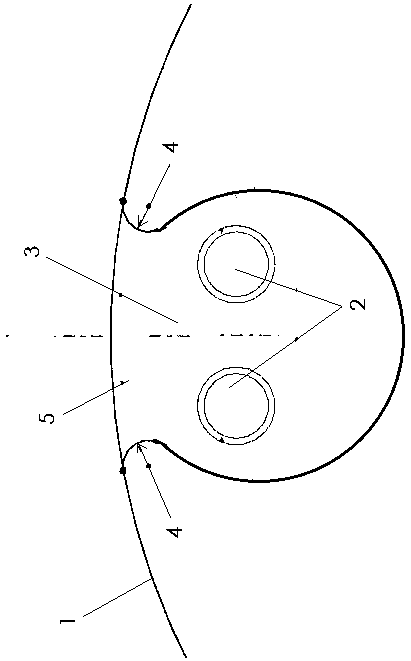

[0027] The intelligent well testing steel wire for distributed optical fiber detection of the present invention comprises a steel wire main body 1, an optical fiber unit 2 and a sealant 3, the steel wire main body is a steel wire with a groove; the optical fiber unit is located in the groove of the steel wire, and the groove is filled with Sealant, the optical fiber unit is fixed in the groove by the sealant; the maximum inner width of the groove of the steel wire body is greater than the width of the opening.

[0028] The optical fiber unit is composed of a single or multiple detection optical fibers laid in a mosaic type.

[0029] The diameter of the steel wire main body is 2-5mm. Specifically, 2.0mm, 2.3mm, 2.5mm, 2.8mm, 3.0mm, 3.4mm, 3.8mm, 4.0mm, 4.3mm, 4.7mm or 5.0mm can be used.

[0030] The sealant is a temperature-resistant, oil-resistant and pressure-bearing sealant.

[0031] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com