Steam-propelling packer

A packer and push-type technology, which is applied in the field of steam-push packers, can solve the problems of long time required for sealing, long telescopic tubes, inconvenient operation, etc., to improve the success rate of setting seal, good sealing effect, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

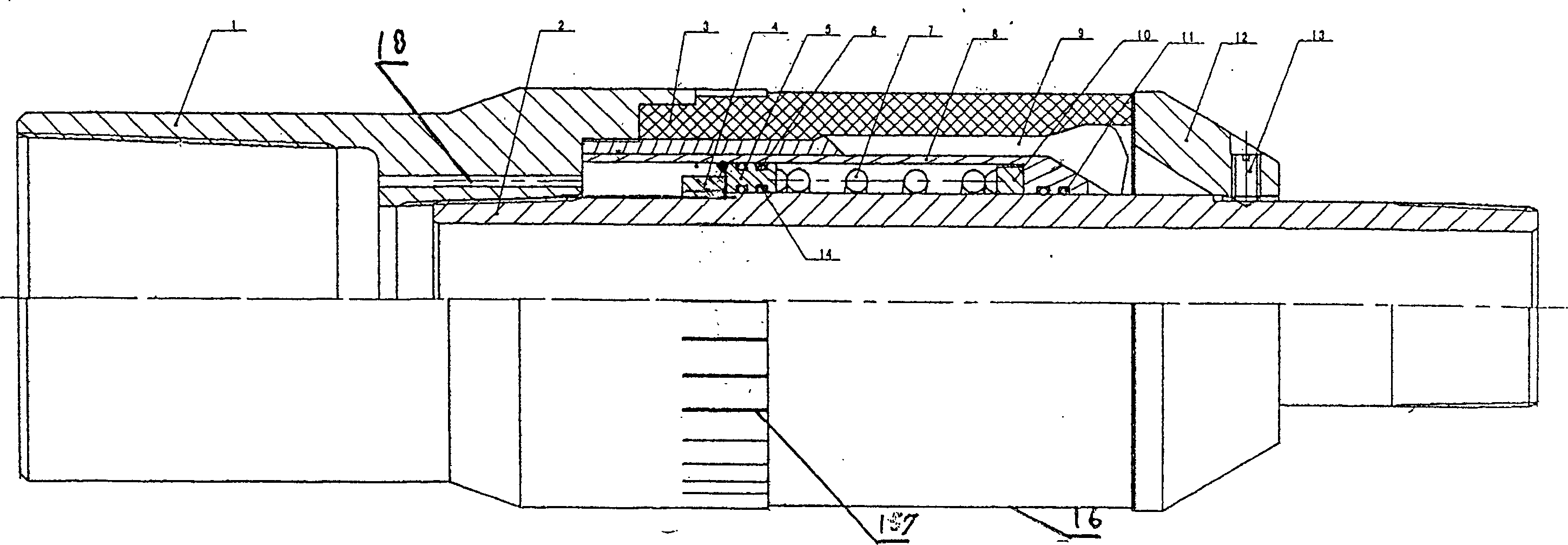

[0014] The present invention is provided by the following embodiments, and the present invention will be further described below in conjunction with the accompanying drawings.

[0015] In the figure, the upper joint is connected with it through the upper threaded buckle of the central tube. The material of the upper joint 1 is 35CrMo, and the upper inner circle is provided with a 4" partial ladder buckle, and the inner circle of the lower part is 2 7 / 8 "TBG buckle, with 15-20° arc on the outer edge, the central tube 2 is made of 35CrMo, and its upper and lower ends are respectively equipped with 2 7 / 8 "TBG buckle, two groups of seal seats 11,14 are respectively used to seal the pusher 8 on the side wall of the middle part. 7 / 8 "Oil pipe or tailpipe are connected, and the material of rubber tube 3 is a hollow cylinder made of polytetrafluororubber, which is packed into the cavity of protection seat 16. Limit cap 4 and positioning seat 10 are all made of 35CrMo Made o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com