Underground hydraulic pump

A technology of hydraulic pumps and jackets, applied in the field of downhole hydraulic pumps, can solve the problems of long operation time, high risk, high operation cost, etc., and achieve the effect of fast speed and convenient lifting and lowering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

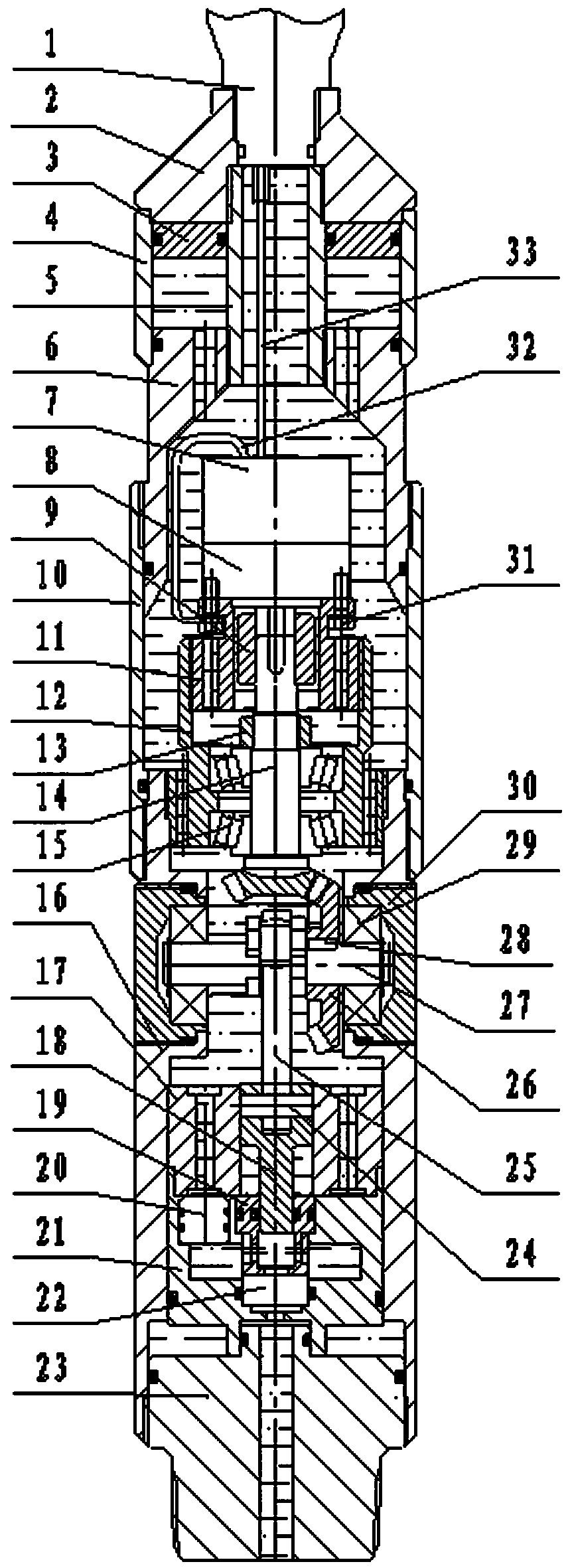

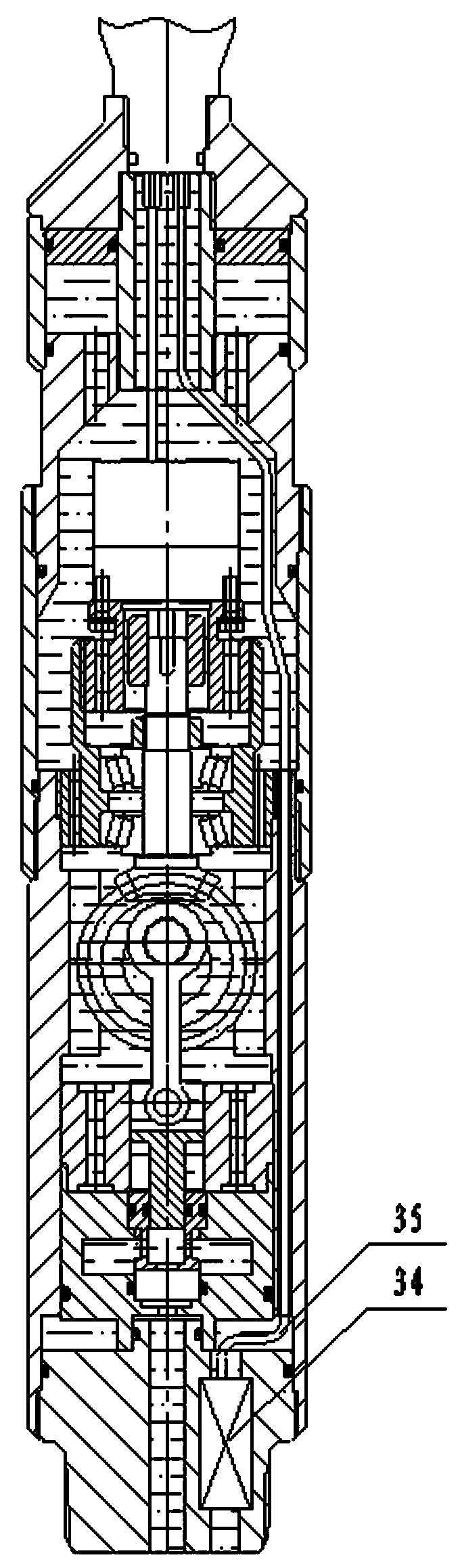

[0012] A downhole hydraulic pump, comprising a tap 1, an upper joint 2, an oil cylinder 4, a central pipe 5, a connecting sleeve 6, an upper outer sleeve 10, an upper inner sleeve 11, a lower inner sleeve 12, a small bevel gear shaft 14, a lower outer sleeve 16, The plunger jacket 17, the tee 21, the lower joint 23, the large bevel gear 26, the gear shaft 27, and the bearing end cover 30 are characterized in that:

[0013] The upper end of the center hole of the upper joint 2 is inserted and threaded with a horse tap 1, the lower end is inserted and threaded with a center pipe 5, the lower end of the center pipe 5 is sleeved and threaded with a connecting sleeve 6, and an oil cylinder is installed between the connecting sleeve 6 and the upper joint 2 4. Oil cylinder 4 is set on the outside of central tube 5 . A piston 3 is installed between the upper joint 2, the connecting sleeve 6, the oil cylinder 4 and the center pipe 5. The piston 3 is sleeved on the central tube 5 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com