String tripping device

A technology for pipe strings and support seats, which is applied in the direction of drilling pipes, casings, drilling equipment, etc., can solve the problems of high operation risk, low work efficiency, discomfort, etc., and achieve the effect of strong practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

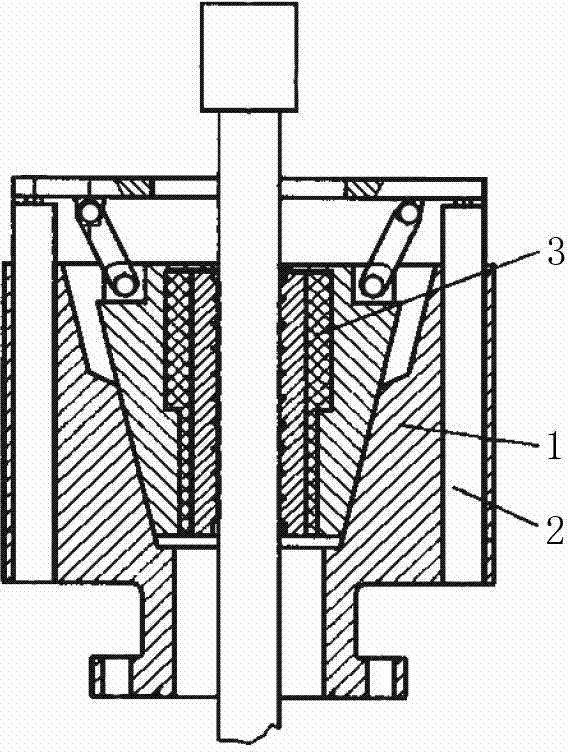

[0010] The pipe string lifting device described in this embodiment includes a support base 1, on which a power cylinder 2 is fixed, and a slip 3 is movably provided inside the support base 1, and the center of the slip 3 is provided with a hole for the oil pipe to enter and exit. Through holes, the slips 3 are fixedly connected with the power cylinder 2, the slips 3 in the present invention are in the shape of an inverted cone, and the support seat 1 is matched with the slips 3

[0011] When in use, insert the tubing into the center of the slip 3, and when the coupling is encountered, start the power cylinder 2, so that the power cylinder 2 drives the slip 3 to move upward, the circle at the center of the slip 3 expands, and when the pipe string needs to be lifted, After the slip 3 is moved onto the pipe string, the power cylinder 2 moves downward, the circle at the center of the slip 3 shrinks, and the slip 3 clamps the pipe string to pull the pipe string out from the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com