Electroplating device for plastic automobile ornaments

A technology for electroplating equipment and automobiles, applied in plating baths, electrolytic processes, electrolytic components, etc., can solve problems such as unfavorable use, inability to use electrolyte, and unfavorable environmental users, to ensure operating efficiency, improve tightness, and recover costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

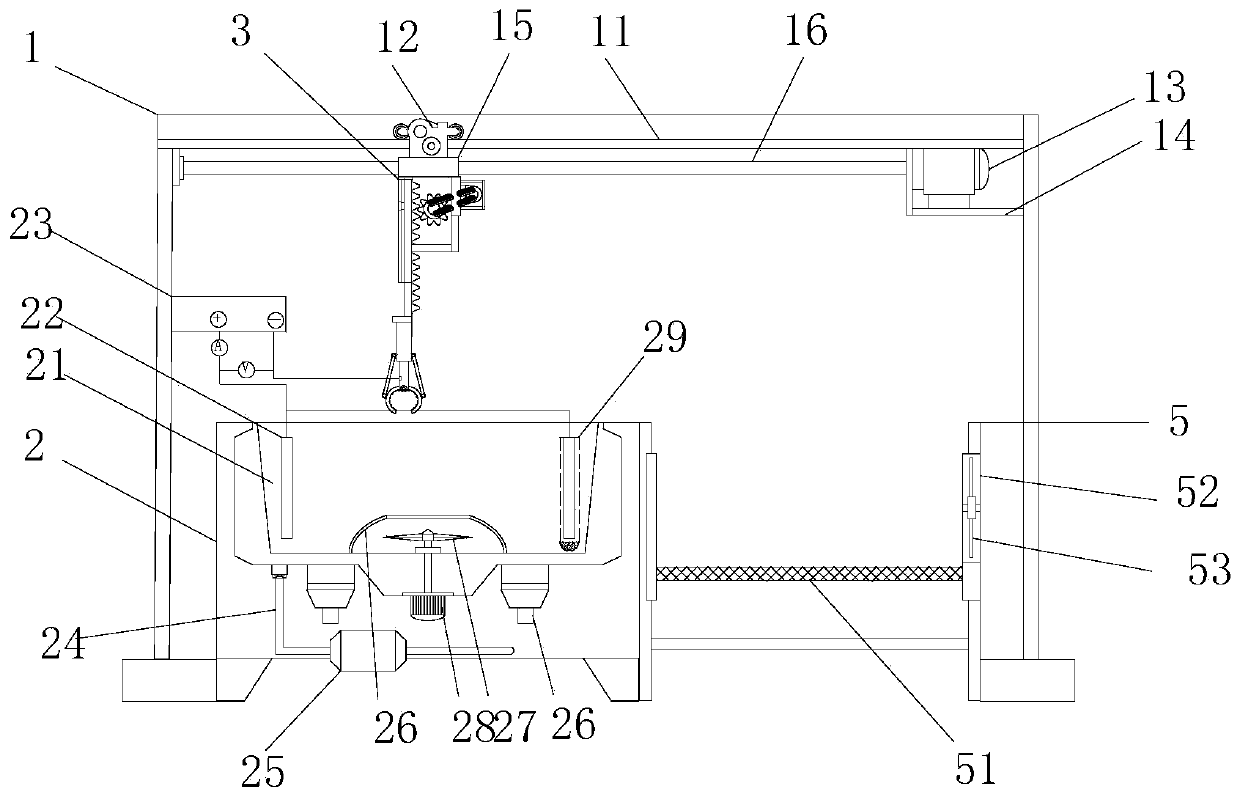

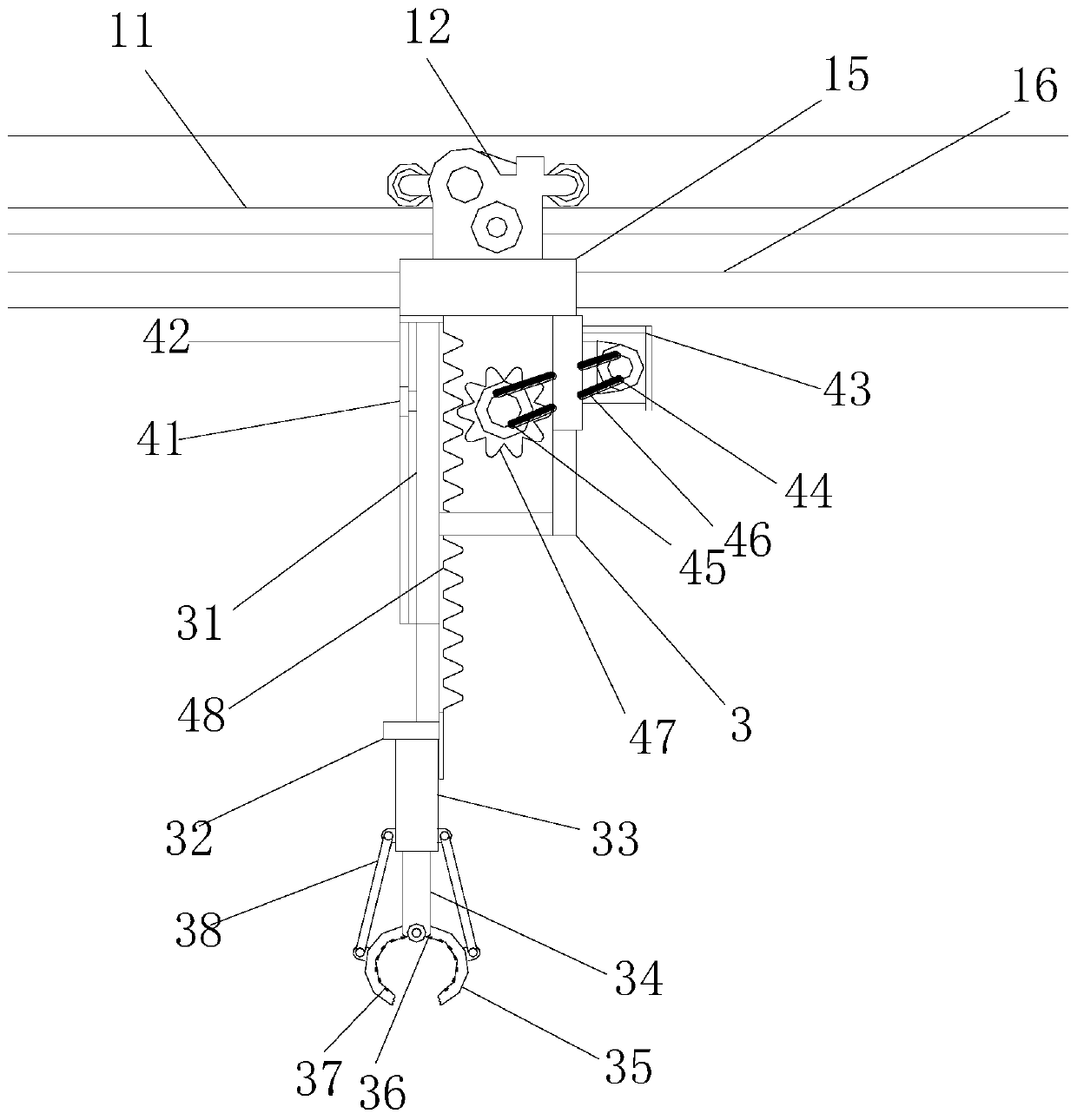

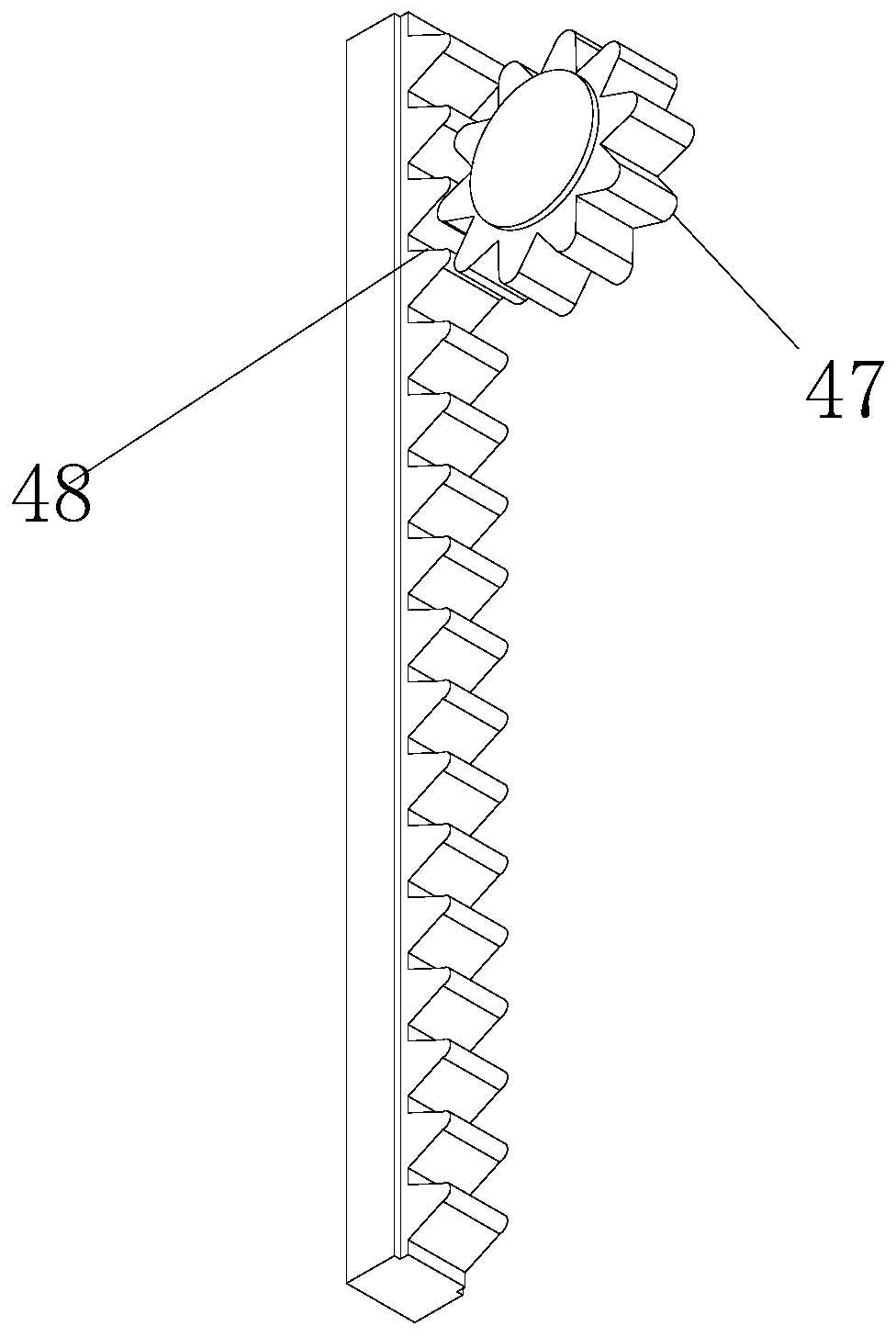

[0033] see figure 1 , an electroplating equipment for plastic automotive accessories, comprising a frame 1, the bottom of the frame 1 is respectively provided with an electroplating box 2 and a storage cavity 5, the electroplating box 2 is used for electroplating treatment, and the storage cavity 5 is used for electroplating. Temporary artifacts. The frame 1 is movably equipped with a lifting frame 3, and the lifting frame 3 is used for clamping workpieces. The electroplating box 2 is provided with an electroplating pool 21, the electroplating pool 21 has a built-in electroplating solution, the bottom of the electroplating pool 21 is externally connected with an infusion conduit 24, and a booster pump 25 is installed on the infusion conduit 24, and the frame 1 A power supply 23 is installed on the side of the power supply 23, and the positive electrodes of the power supply 23 are respectively connected to metal parts 22 (anodes) through several electrical connection lines. T...

Embodiment 2

[0045] see figure 1 , this embodiment serves as a further optimization of the first embodiment, on the basis of which, the storage chamber 5 is built with a loading net plate 51, and the bottom of the loading net plate 51 is provided with a liquid contact chamber. A blowing cavity 52 is provided on the side of the storage cavity 5, and a blower 53 is installed in the blowing cavity 52.

[0046] For the workpiece that has been electroplated, the application uses the above-mentioned lifting and horizontal displacement mechanism to place the workpiece on the loading net plate 51, and the liquid on the surface of the workpiece passes through the loading net plate 51 and flows into the liquid receiving chamber for recycling. Blowing cavity 52 is arranged on the side, further carries out air-drying to workpiece, improves its blow-drying speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com