Fast adjustment trifurcate synchronous telescopic rotation clamp

A telescoping, rotating and fast technology, which is applied in the direction of grinding workpiece supports, etc., can solve problems such as deformation, reference hole deformation, loss of function, etc., and achieve the effect of accurate hole position, convenient installation and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

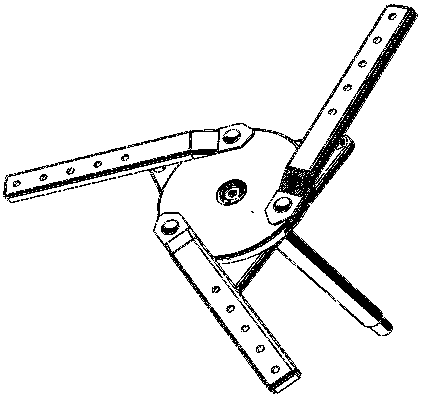

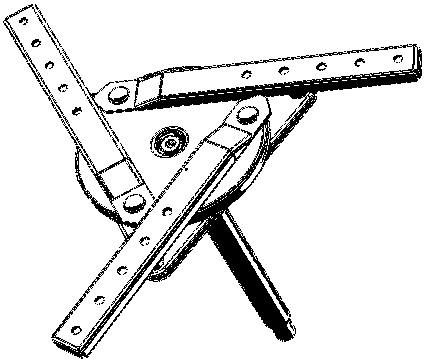

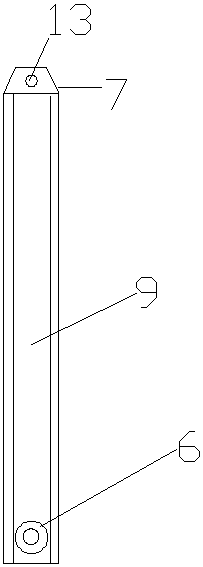

[0031] Implementation method: such as figure 2 The device shown in the figure can drive the rotating disk to rotate during the rotation of the drive shaft. When rotating, the supporting arm of the fast chute is pulled, such as our current square rotation. At the same time, the supporting arm of the fast chute is pulled by the pulling of the rotating disk. It will gradually rotate counterclockwise, because the bottom of the support arm of the quick chute is provided with a chute, and the chute is locked by the guide positioning sheath. to move so that at the end the quick chute support arms are fully extended into figure 1 state shown, whereas conversely, we start from figure 1 Rotating counterclockwise in the fast chute support arm, the guide positioning sheath fitted in the support arm of the fast chute will move from the position closest to the center of the circle to the outside of the center of the circle, and finally reach the outermost side of the support arm of the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com