Turning hole making device

A hole processing and flipping technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of increasing manufacturing costs, wasting man-hours, and blurring positioning, achieving easy operation, cost saving, and reliable positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

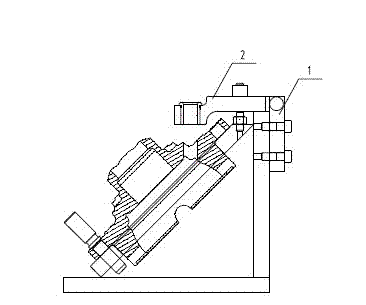

[0008] The present invention is a reversible hole processing device, which includes a drilling device 1 and a pressing device 2. The positioning part of the drilling device is realized by means of two pins on one side, that is, a positioning notch plus a positioning hole, so as to achieve the purpose of precise positioning. Design a stop that fits the workpiece at a specified position on the bottom plate, and design three positioning holes on the bottom plate according to the hole position requirements of the workpiece. The three holes are used in conjunction with the stop in turn to achieve precise hole positions while rotating the workpiece. position. The drilling part of the drilling device is fixed on the device, and the template is moved by connecting and turning the rotating shaft, so as to achieve the purpose of non-disassembly, convenient workpiece clamping and non-interference. The pressing device is fixed on the main body and the drilling part through the stud connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com