Method and device for punching multiple holes on square tube, and aerator manufactured therefor

A technology of aerator and punch, applied in the field of aerator, fishery and aquaculture machinery, namely aerator, can solve the problems of difficult hole position control, many burrs on the reverse side, slow drilling efficiency, etc. Bit accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

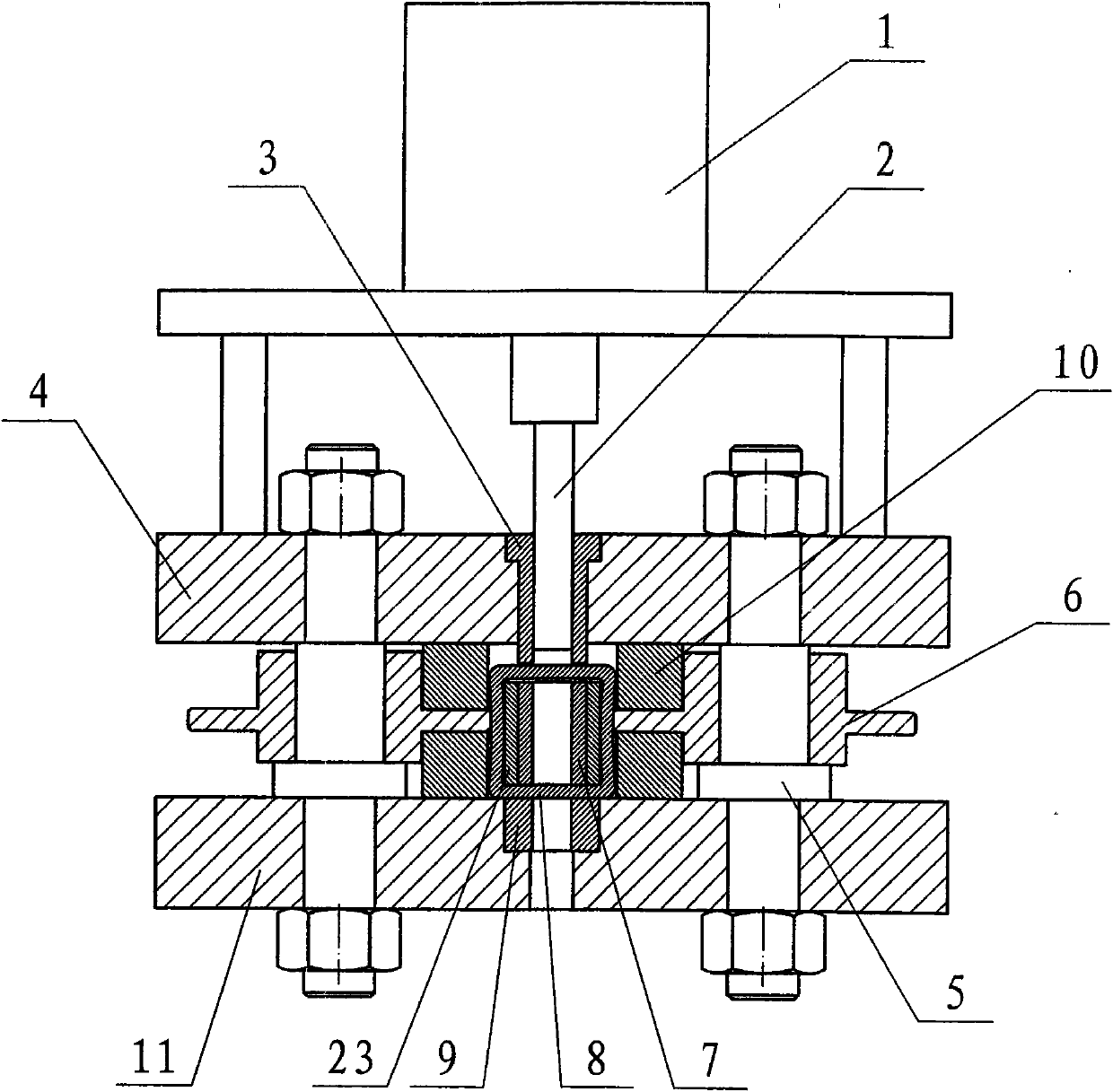

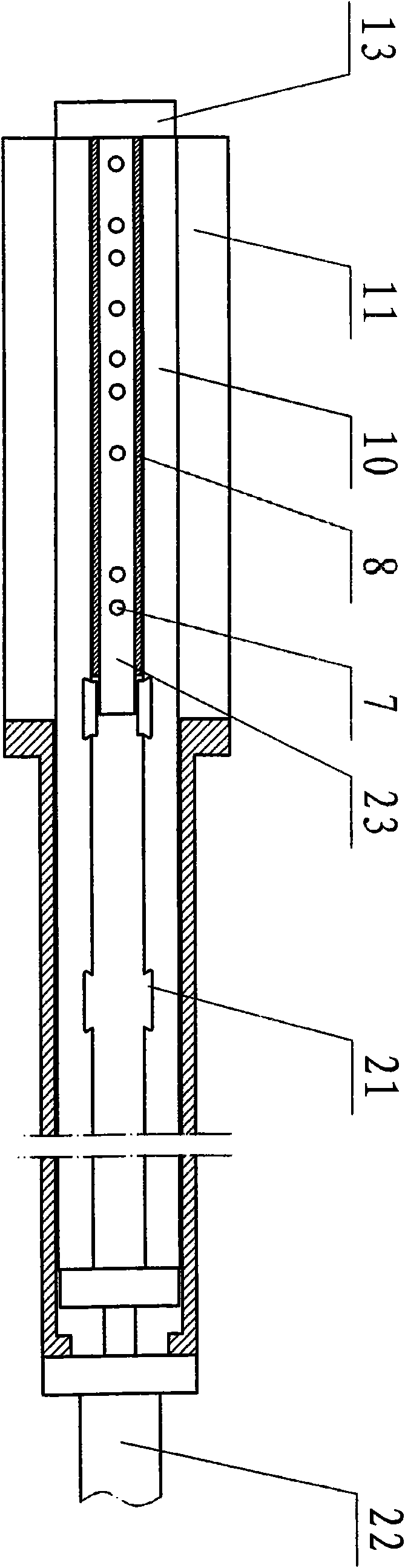

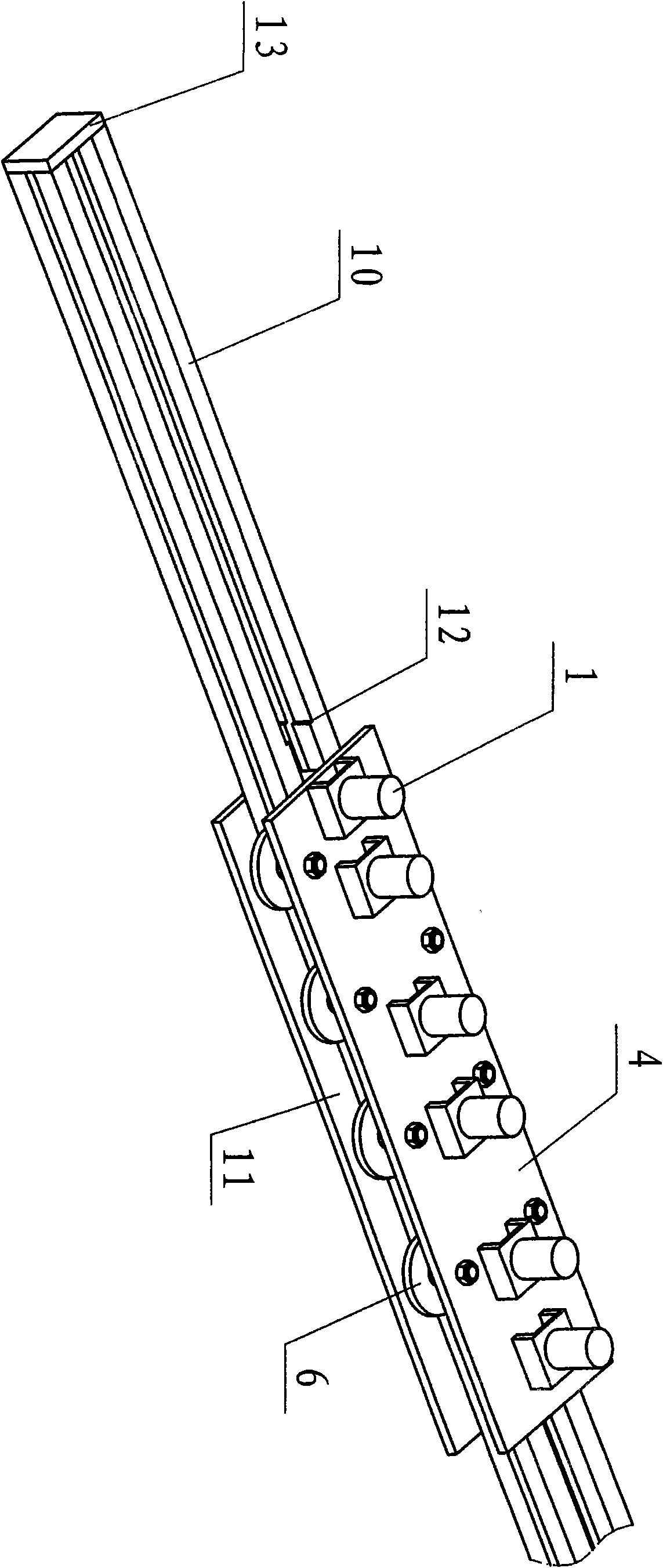

[0025] The present invention will be further described below with specific examples, see Figure 1-7 :

[0026] A method for punching holes in a square tube. Put the square tube (workpiece) into the mold. After the punch goes down to punch the upper hole, continue to punch the lower hole. When punch 2 goes down, the waste in the upper hole is punching The front of the head 2 in the advancing direction is pressed against the outer die 9 by the punch 2 and separated from the workpiece 8 with the waste material below.

[0027] A device for punching holes in a square tube, which is mainly composed of punch 2, inner die 7, outer die 9, upper template 4, lower template 11, support member 5, positioning member, etc., upper template 4 is equipped with guide sleeve 3 , The punch 2 corresponds to the inner die 7 and the outer die 9 through the guide sleeve 3, the inner die 7 is mounted on the square bar 23, the square bar 23 and the inner die 7 can be made into one body, and the outer die 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com