Process for drilling side of furniture plate and special processing device thereof

A processing device and plate technology, applied to wood processing equipment, drilling machines, manufacturing tools, etc., can solve the problems of cumbersome processing, inaccurate positioning, complex equipment, etc., and achieve the effect of simple processing technology, convenient operation, and accurate hole positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

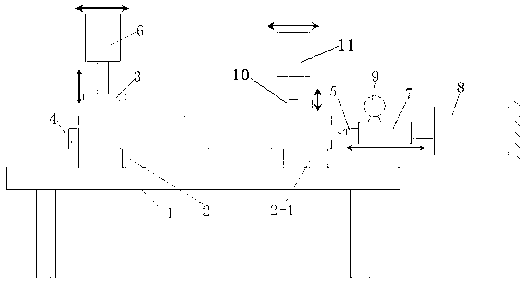

[0018] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0019] The invention relates to a side drilling process of furniture boards, which is carried out according to the following process:

[0020] a) Place the plate flat on a horizontal platform, and the unprocessed end leans against an L-shaped positioning block set on the horizontal platform;

[0021] b) Drive a vertical lifting main pressing block and auxiliary pressing block to press against the upper surface of the unprocessed end and the processed end to prevent the unprocessed end from jumping during processing;

[0022] c) Drive a number of drill bits located on the processing end side of the plate to feed towards the end of the plate to complete drilling on the side of the plate;

[0023] d) After the drilling process is completed, the drill bit returns,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com