Columnar plug-in screw turning machine

A screw machine and plug-in technology, applied in the field of plug-in processing equipment, can solve the problems of long time consumption, waste of manpower, low work efficiency, etc., achieve the effect of accurate hole position and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

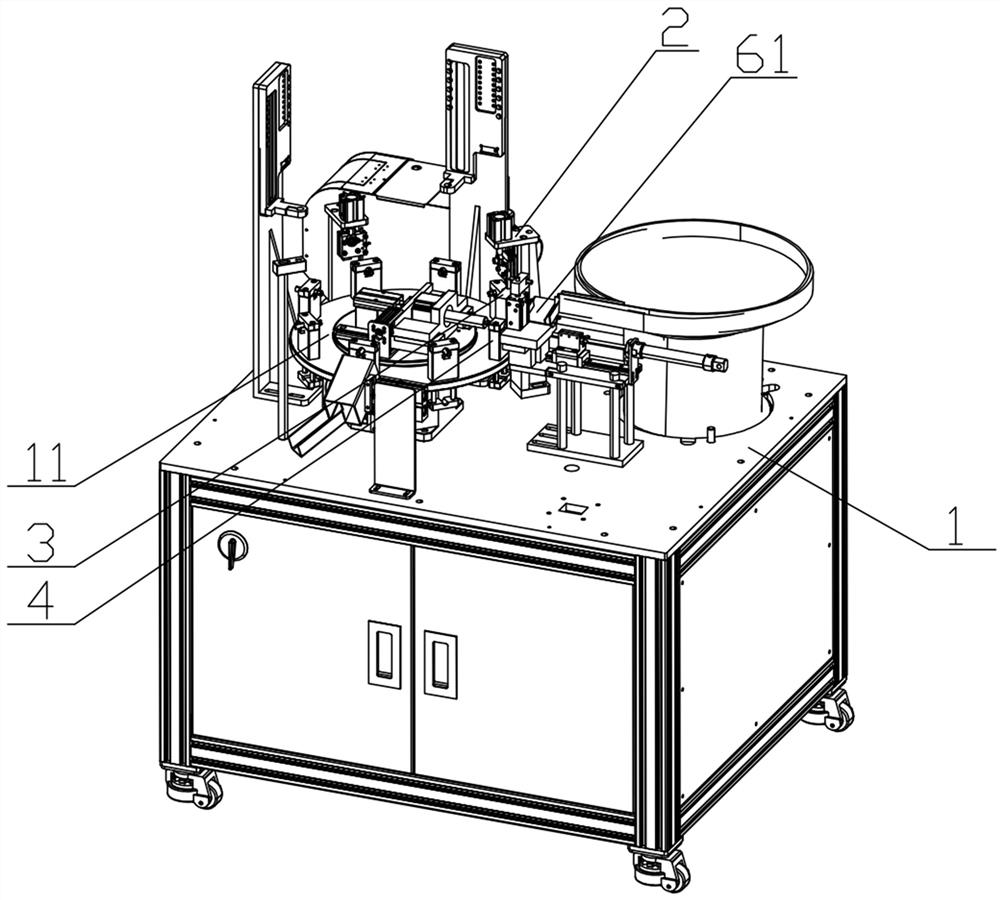

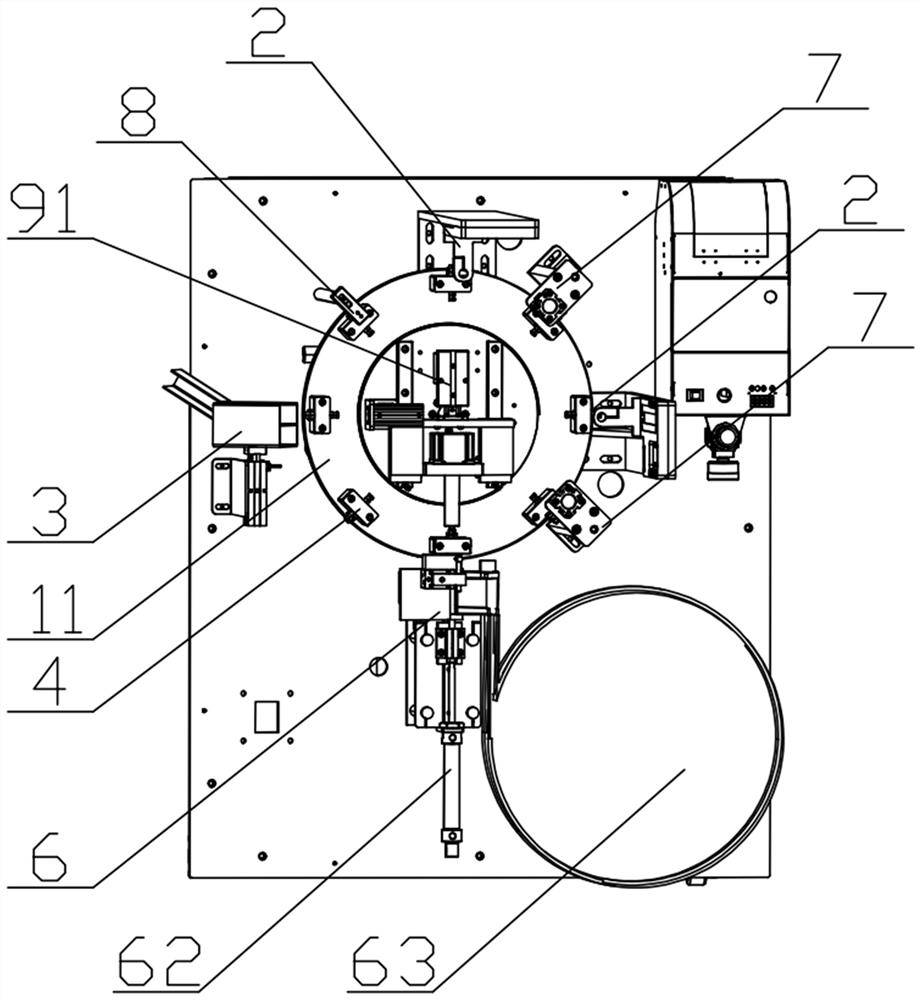

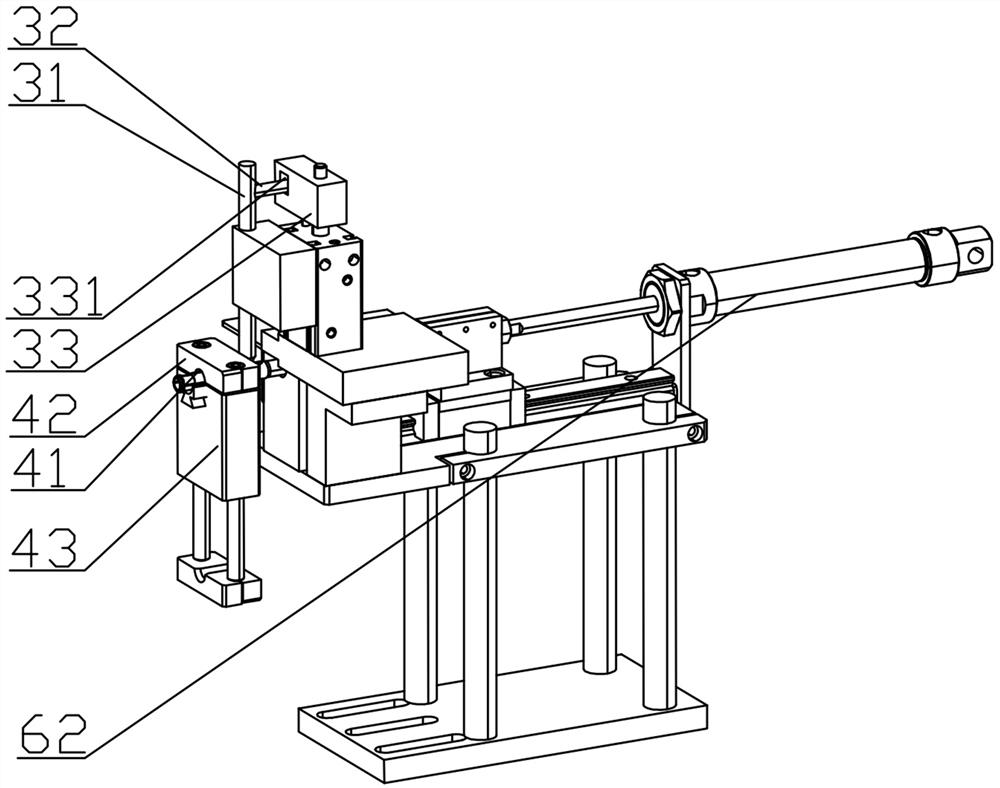

[0025] Screwdrivers with columnar inserts, such as Figure 1-4 As shown, it includes a frame 1, and the frame 1 is provided with a delivery platform 11, a screw device 2 and a plug-in adjustment device. The delivery platform 11 can be linear or turntable, such as figure 1 As shown, in this embodiment, taking the conveying platform 11 as a turntable as an example, the conveying platform 11 is an annular turntable, the screw-in device and the plug-in adjustment device are arranged on the outer peripheral side of the turntable, and the rotating power source 51 and the ejection cylinder 91 are arranged On the inner peripheral side of the turntable, the rotating power source 51 and the ejection cylinder 91 do not rotate together with the turntable, so that its working position is fixed, and the turntable only plays the movement of the plug-in fixing device transferred thereon. Screwing in the screw device 2 belongs to the equipment known to those skilled in the art, and its specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com