Punching die with opposite-punching mechanism

A punching die and elastic mechanism technology, which is used in punching tools, manufacturing tools, metal processing equipment, etc., can solve the problems of unreasonable punching die structure design, inability to meet modern production, and unusable round pipe workpieces. The effect of improving workpiece accuracy, improving service life and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

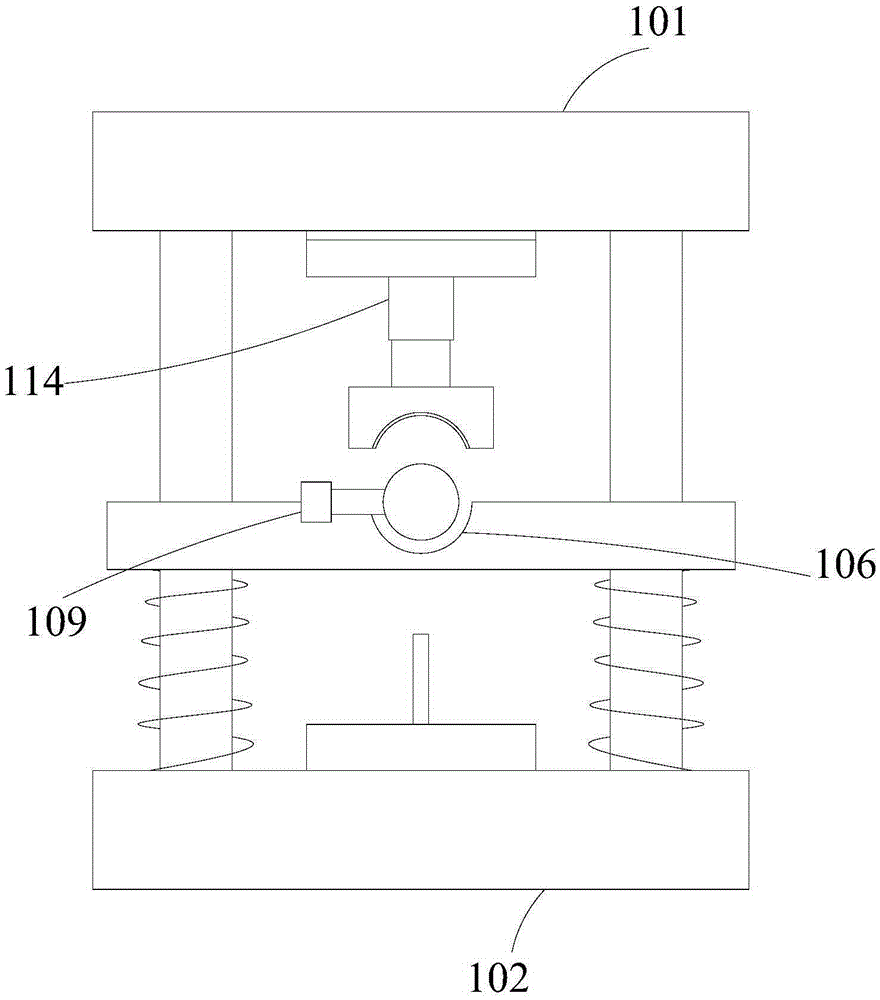

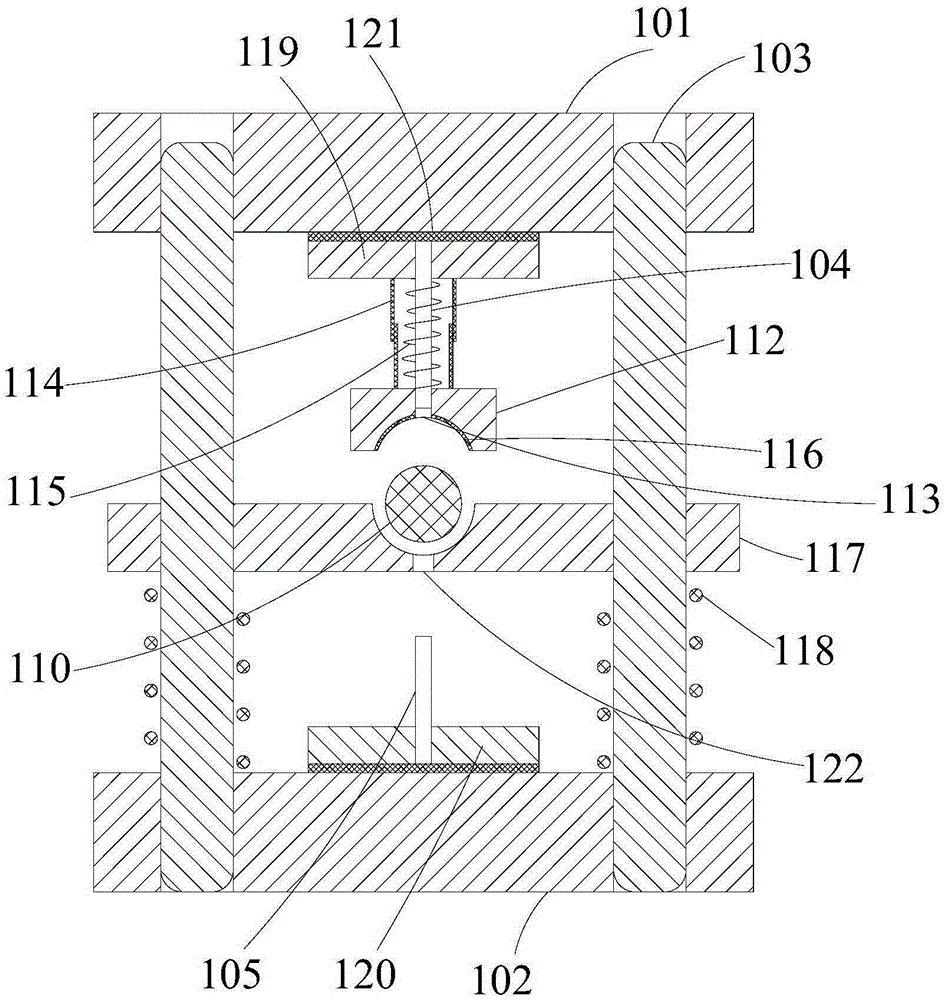

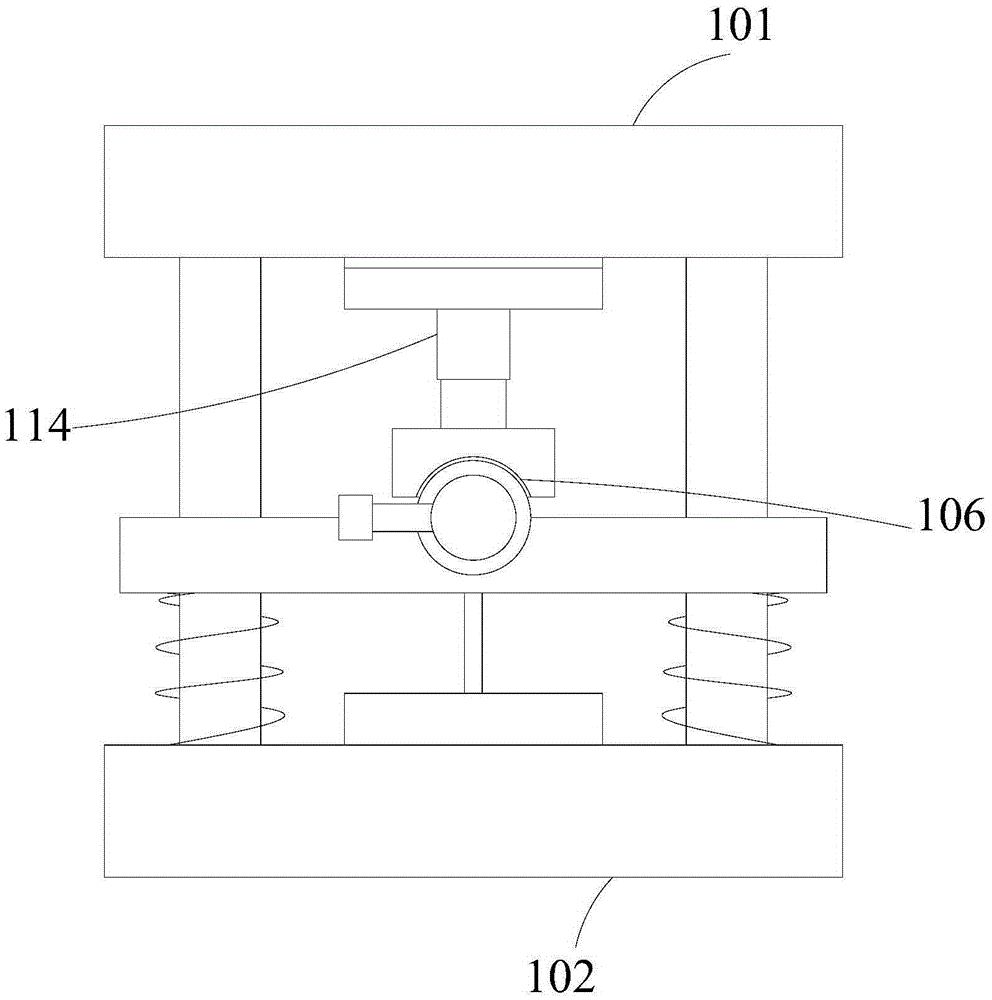

[0077] A punching die with a hedging mechanism, comprising an upper die base 101 and a lower die base 102, the upper die base 101 and the lower die base 102 are connected by a guide post 103, and an upper punch 104 is connected to the bottom of the upper die base 101; The top of the lower mold base 102 is also connected with the lower punch 105, between the upper mold base 101 and the lower mold base 102 is provided with an intermediate mold base 117, the intermediate mold base 117 is connected with the lower mold base 102 by a return spring 118, and the return spring 118 Sleeved on the outside of the guide post 103; the middle mold base 117 is provided with a round tube placement part 106, and the round tube placement part 106 is an arc-shaped sinker structure, and the bottom of the arc-shaped sinker is provided with the bottom of the middle mold base 117. The circular hole 122.

[0078] Upper punch 104 is connected with upper die base 101 through upper fixing seat 119, and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com