Leather carving closestool cover process

A technology of toilet lid and leather carving, which is applied in the crafts used to produce decorative surface effects, decorative art, seat or lid for toilet, etc. It can solve the problems that glue is not easy to wipe off, the retention effect is not long, and the visual effect is affected. , to achieve the effect of various colors, smooth surface and high paint hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

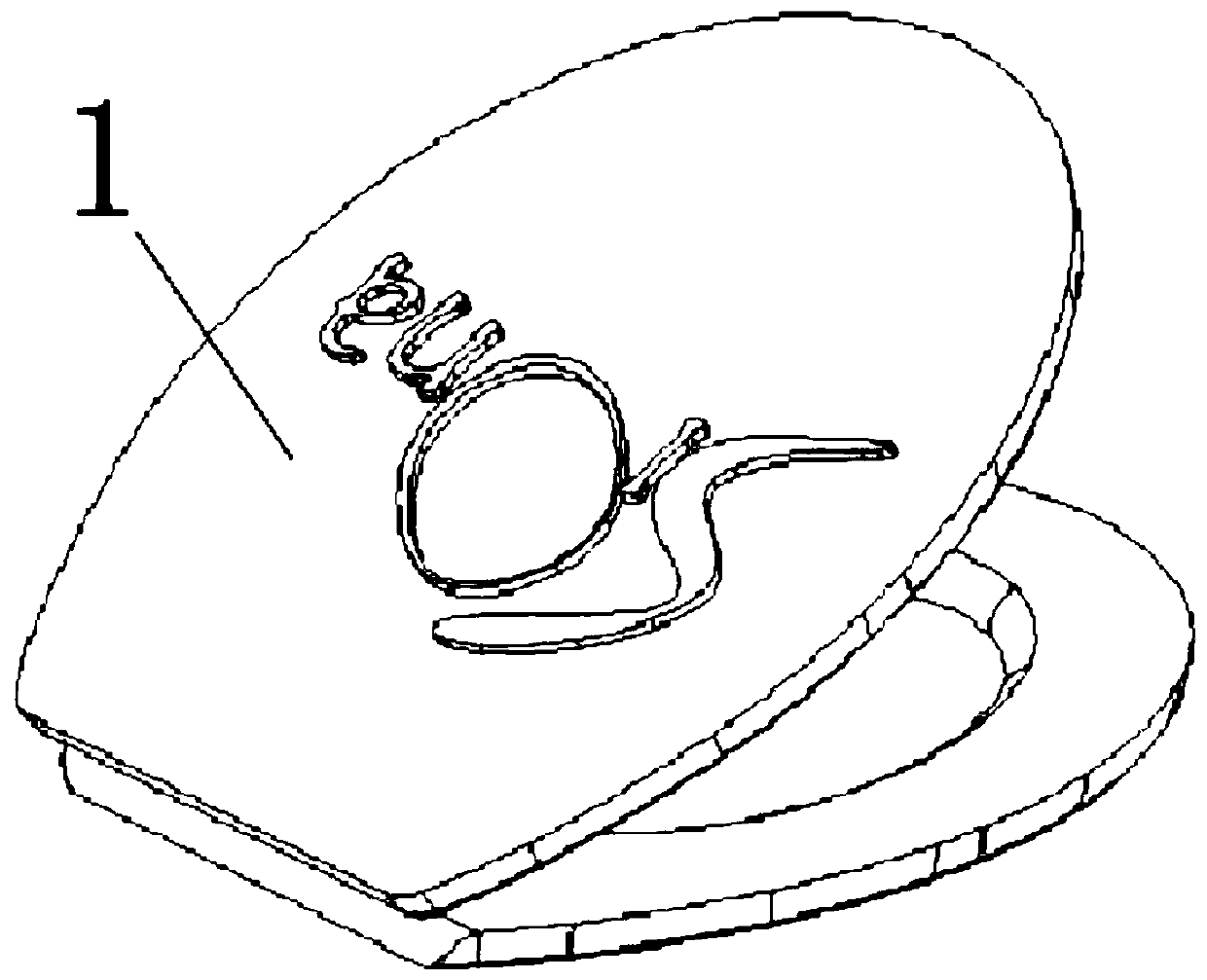

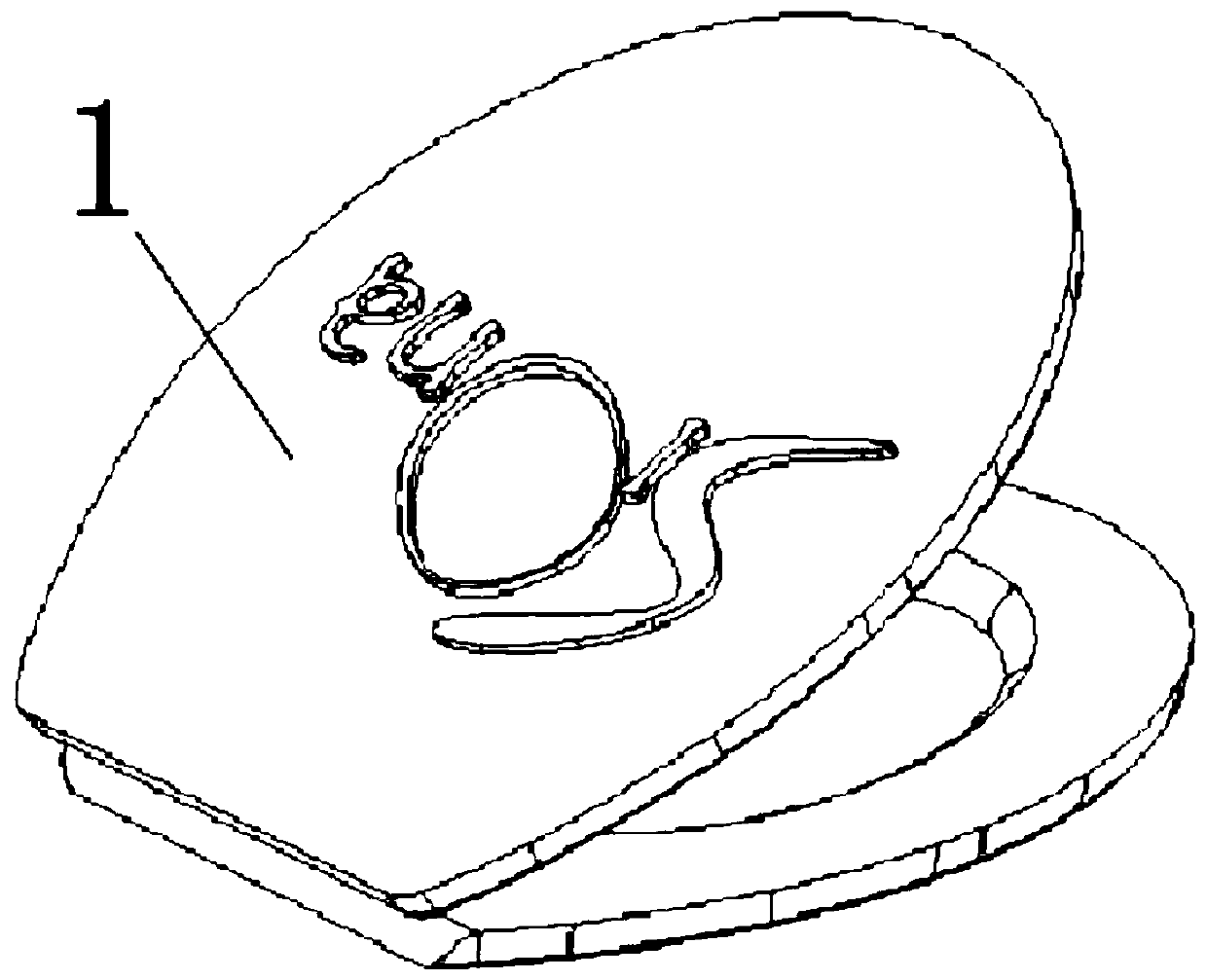

[0031] A leather carving toilet cover process, comprising the following steps:

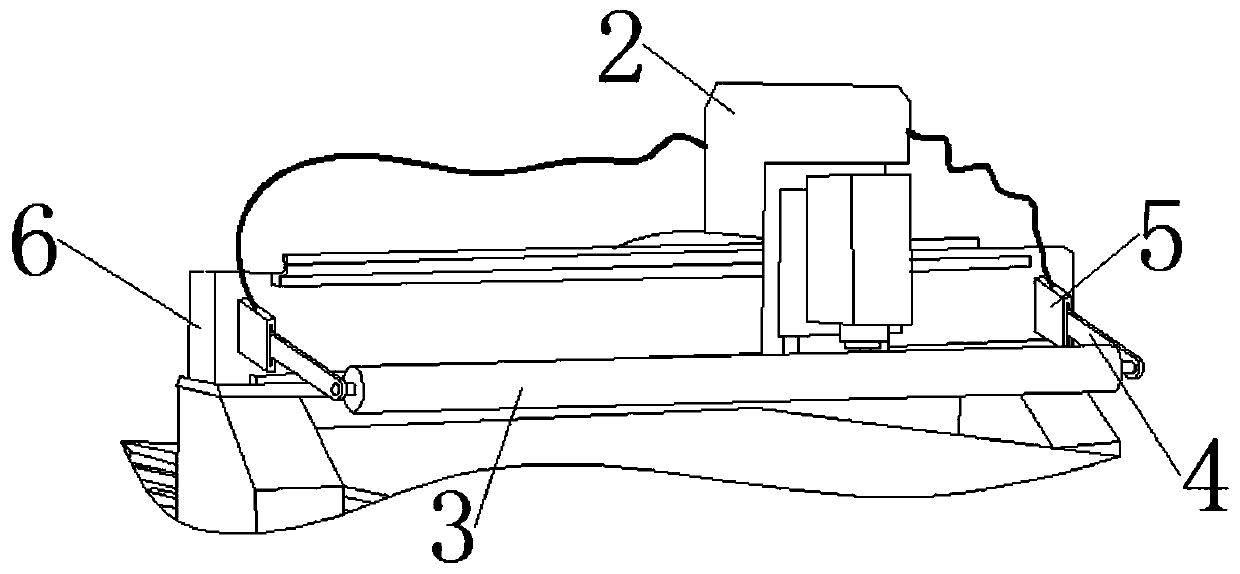

[0032] (1) Engraving: Pre-install the lowering component on the beam 6 of the CNC engraving machine, put the density board with white melamine film on the surface on the engraving machine workbench, and then create the drill bit and milling cutter on the CNC computer according to the drawing, That is, input processing parameters. Then start to load the tool and create the tool path. After the commissioning is completed, start the equipment, and start drilling 3.0 holes, then 5.8 holes according to the programmed procedures, and finally carve the inner and outer contours to form the toilet seat cover blank. Among them, when the CNC engraving machine starts to engrave, the pressing component will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com