Automobile frame assembly

A technology of automobile frame and assembly, which is applied in the direction of vehicle parts, substructure, transportation and packaging, etc. It can solve the problems of affecting the strength of the beam, the single shape, and increasing the cost, so as to improve the appearance, good consistency, and The effect of precise hole position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

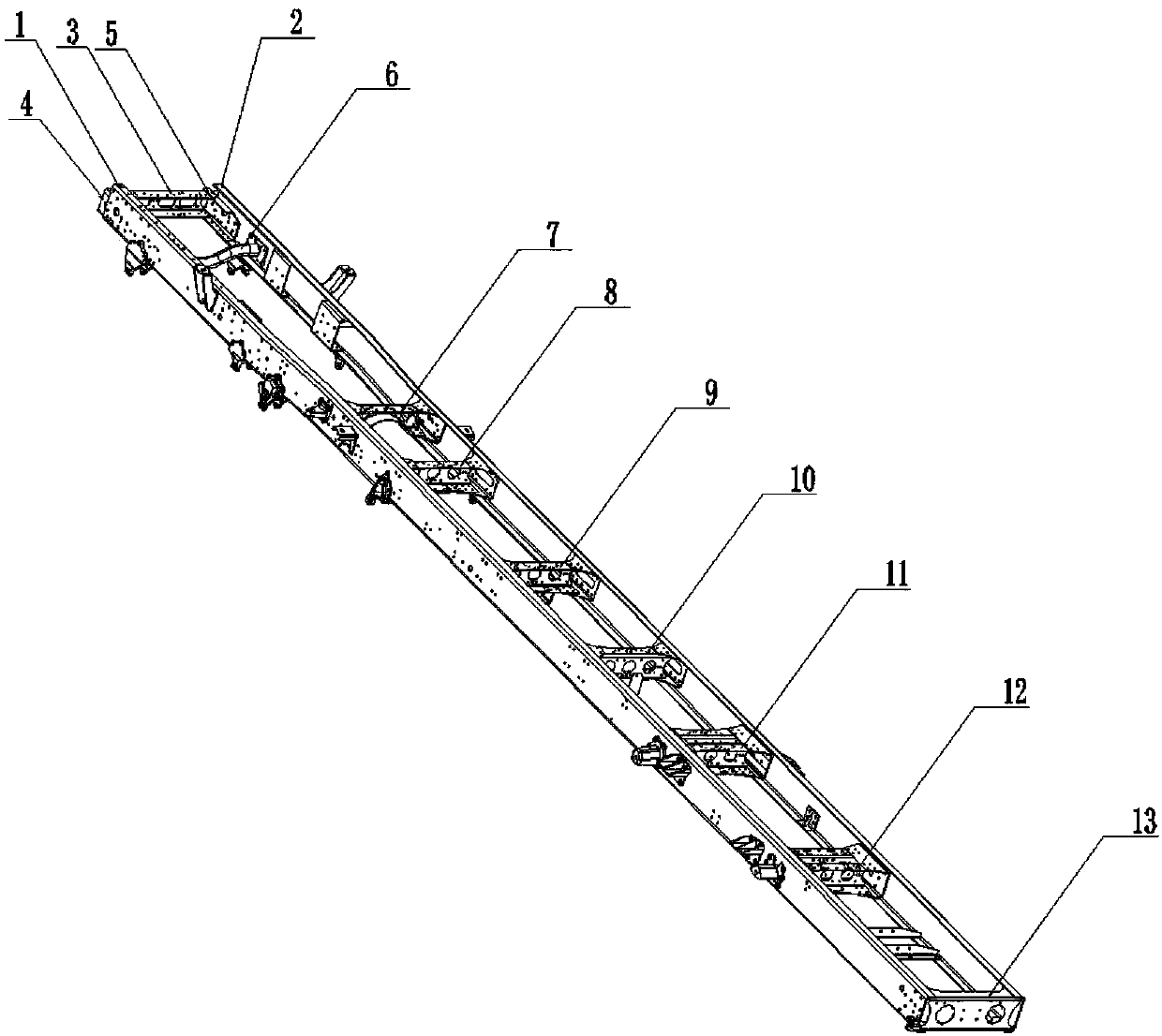

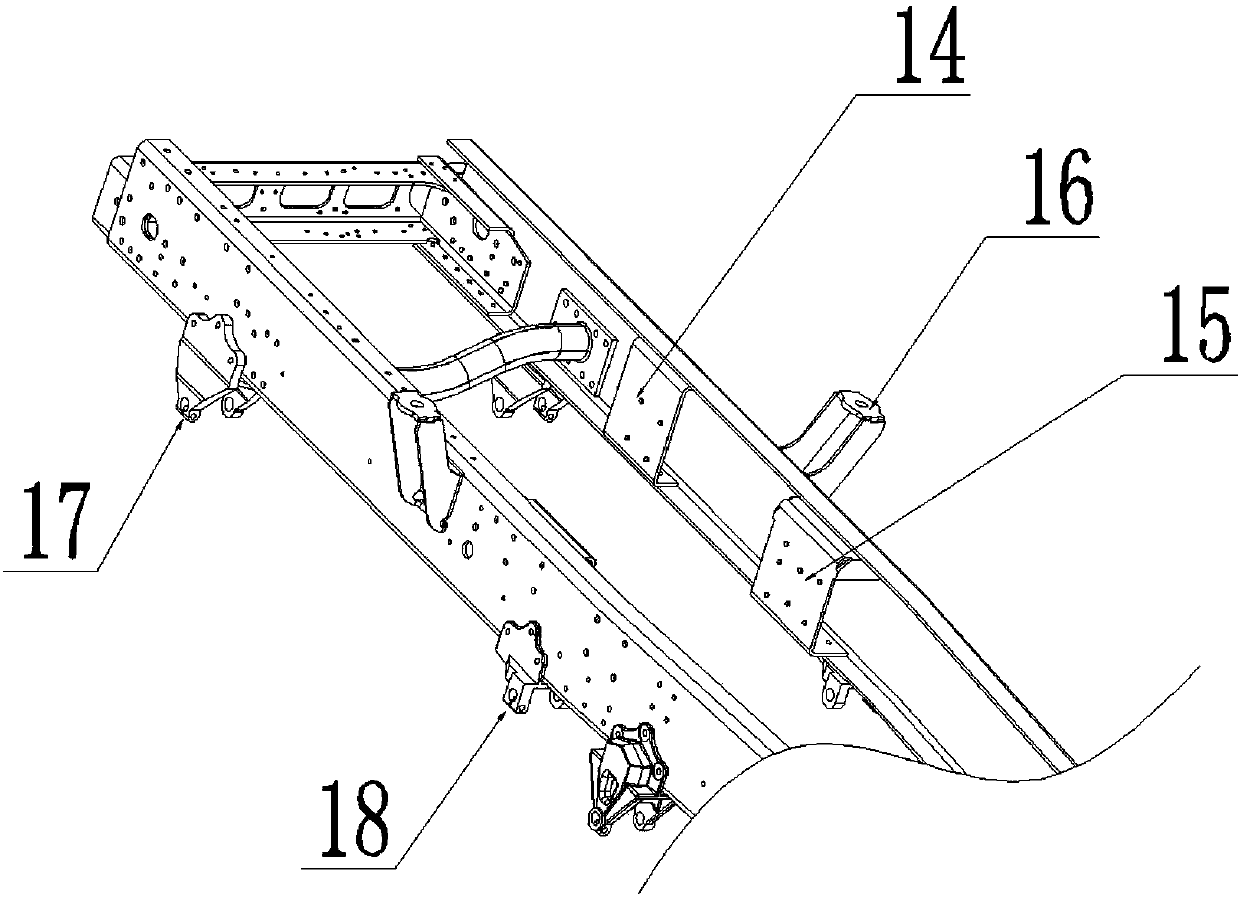

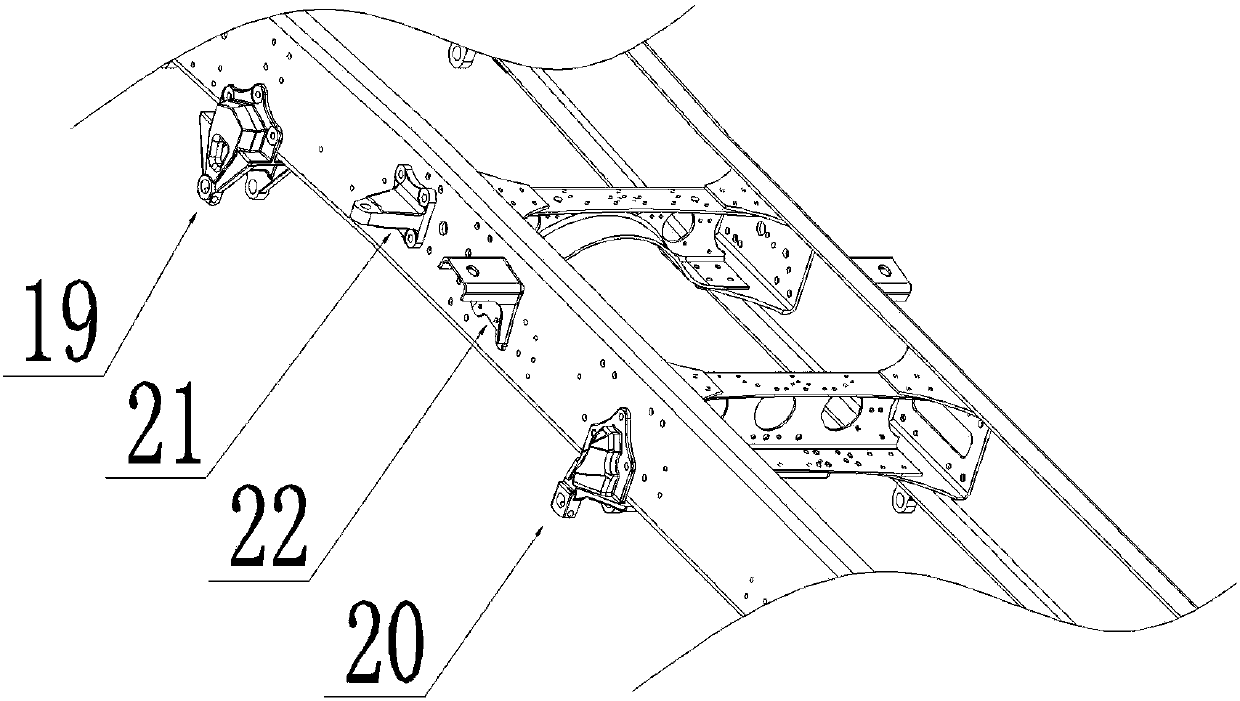

[0023] Such as Figure 1-Figure 5 The automobile frame assembly shown in the figure has a left longitudinal beam 1 and a right longitudinal beam 2. The left and right longitudinal beams adopt a U-shaped design and adopt domestic advanced roll forming-three-side punching-plasma cutting-bending forming The frame assembly adopts a symmetrical layout, and the U-shaped opening of the longitudinal beam is arranged inward. The developed left and right longitudinal beams are made of QSTE650 high-strength girder plates, which have high rigidity and strength and play a greater role. carrying capacity.

[0024] Set up the first crossbeam 3, the connecting piece 4 of the front section of the left longitudinal beam, and the connecting piece 5 of the front section of the right longitudinal beam. After the three are fastened with 10.9-grade bolts, they are installed on the left longitudinal beam 1 and the right longitudinal beam 2 with 10.9-grade bolts. Fasten, install on the riveting line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com