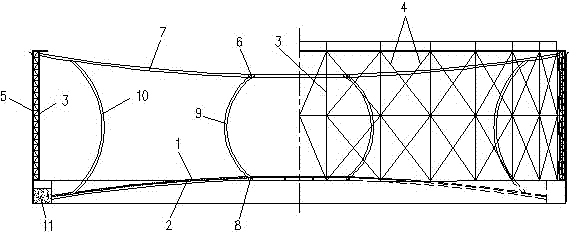

Gasholder pillow type piston

A gas tank and piston technology, which is applied to the piston field of the gas tank, can solve the problems of yield instability, low work safety and stability on the side of the piston, and achieve the effects of enhancing rigidity and strength, strong force bearing capacity and increasing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

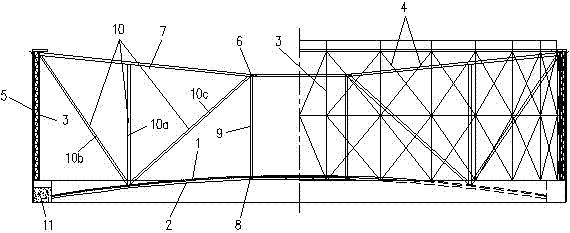

Embodiment 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the cross-bracing beam 7 is an oblique straight beam whose end connected to the upper ring beam is lower than the end connected to the column, and the first intermediate truss 9 is a straight support rod I; The second intermediate truss 10 includes the straight support bar II10a connecting the cross brace beam 7 and the lower support truss 2, the inclined support bar I10b connecting the upright column 3 and the straight support bar II10a, and the inclined support bar II10a connecting the straight support bar II10a and the upper ring beam 6 Rod II 10c; a straight rod-shaped truss is adopted, which is simple to manufacture and can reduce the manufacturing cost of the truss. Other structures in the pillow type piston of the gas cabinet of the present embodiment are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com