Automatic cleaning device for sliding plate combined assembly trolley track

An automatic cleaning and driving device technology, applied in cleaning devices, transportation and packaging, conveyor objects, etc., can solve problems such as high cleanliness requirements, unqualified, affecting production efficiency, etc., to avoid manual removal and automation High degree, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

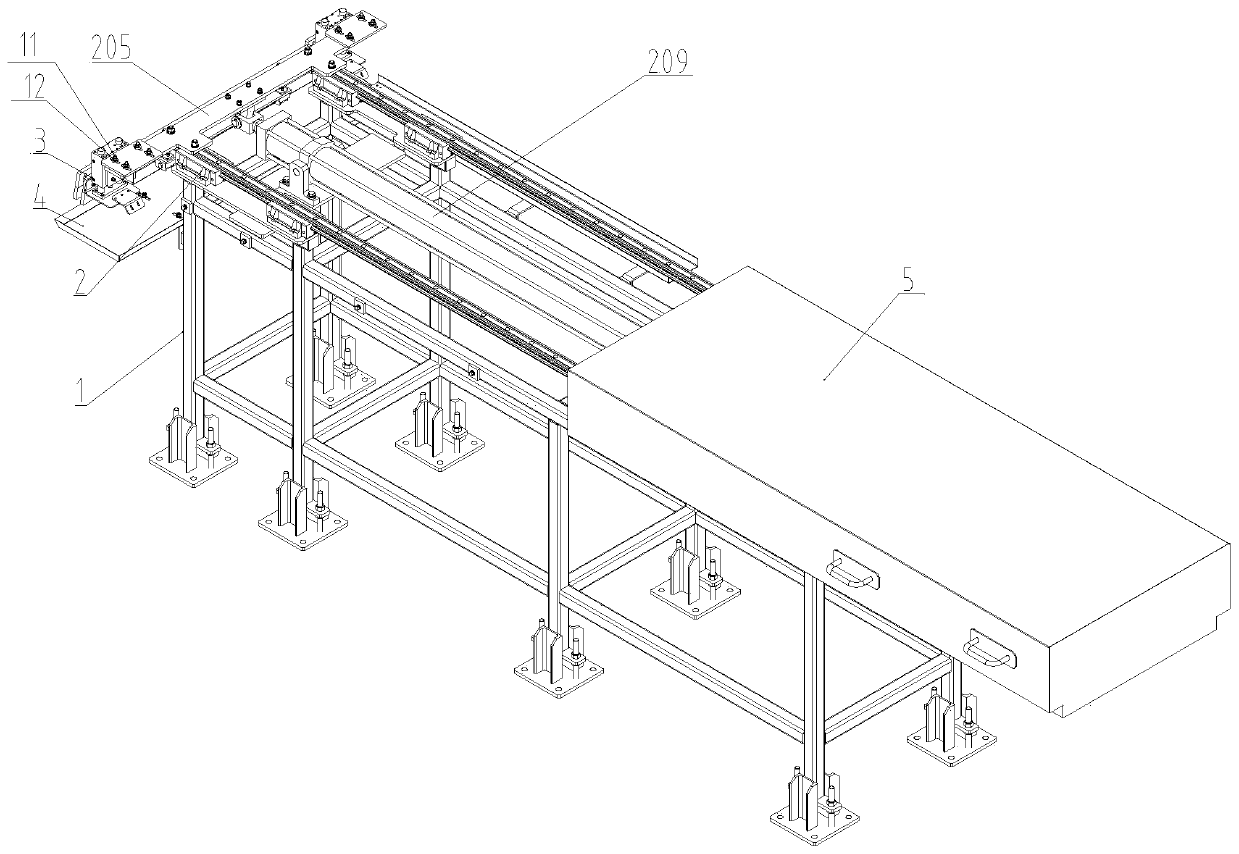

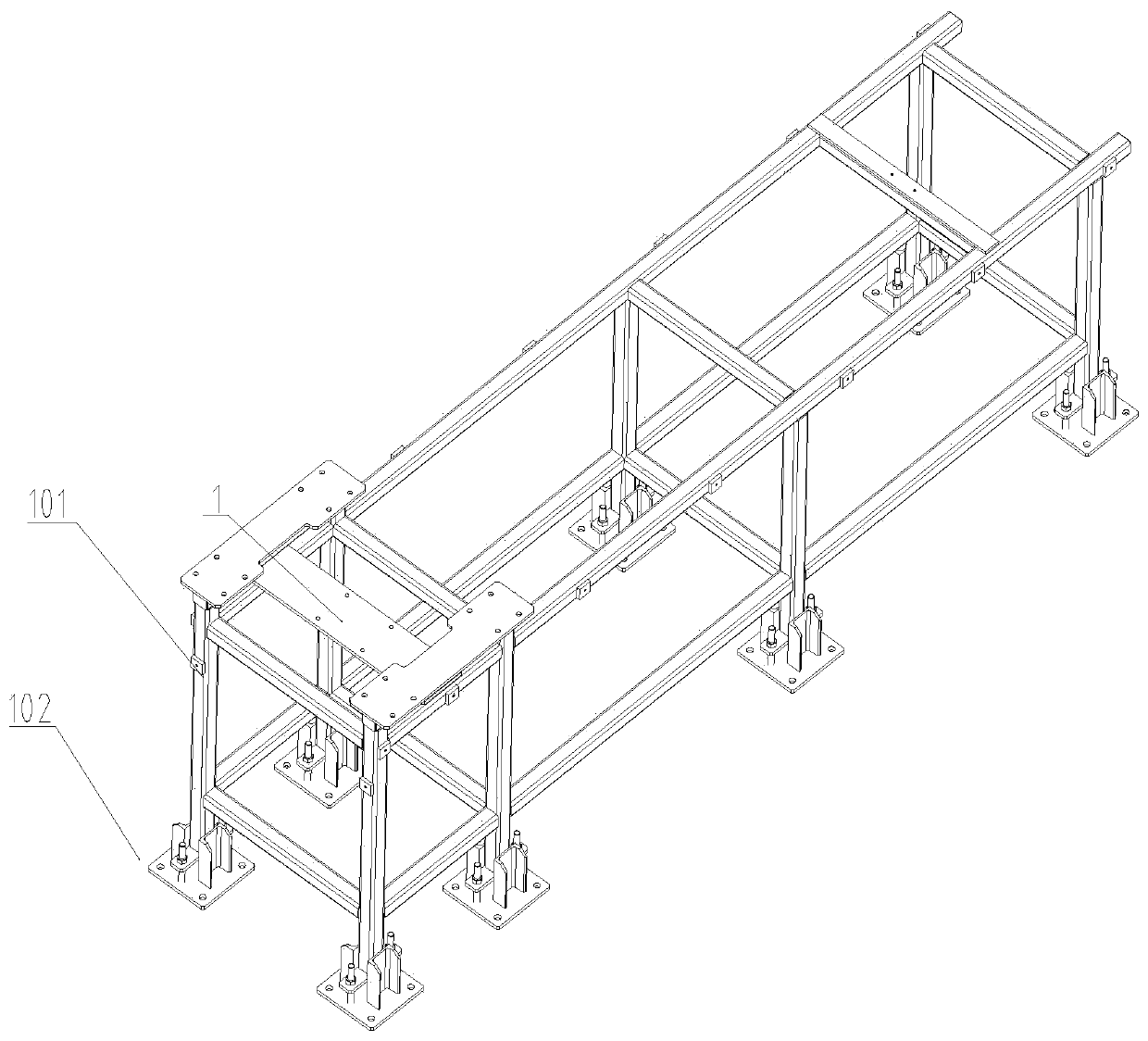

[0026] Such as figure 1 The automatic cleaning device shown in —9 includes device support 1 (comprising main frame 101 and anchor 102, each component adopts modular design, and each component adopts bolt connection), linear telescopic drive device 2, cleaning head assembly 3, material tray 4 and the dust cover 5, used in conjunction with the lifting slide 6 and the sliding plate assembly trolley track 7, each part adopts a modular design, and each part is connected by bolts.

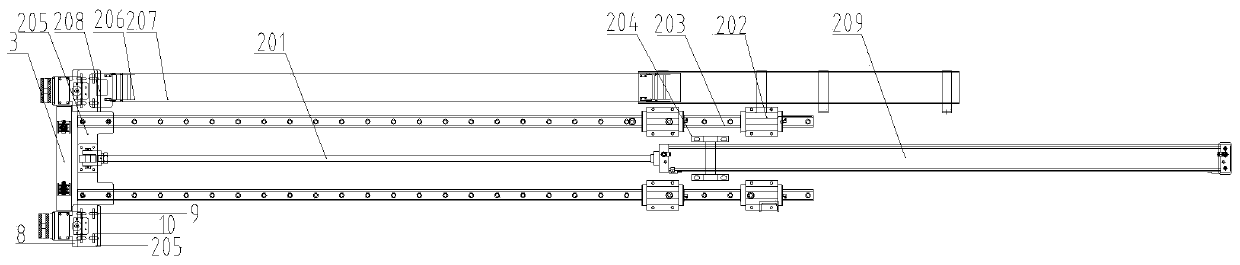

[0027] Such as image 3 As shown, the linear telescopic drive device 2 includes a telescopic drive cylinder 209 arranged horizontally and linear slide rails 203 arranged in parallel on both sides of the telescopic drive cylinder 209. The two sides of the telescopic drive cylinder 209 are also provided with slide rails that cooperate with the linear slide rails ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com