Flexible decorative sheet and manufacturing method thereof

A manufacturing method and a decorative sheet technology, applied in the field of building materials, can solve the problems of aging resistance of flexible face tiles, difficult to meet market requirements for stain resistance, fire resistance can not reach Class A, and the effect is not particularly good, and achieve aging resistance. Excellent, good glaze adsorption, reducing the effect of the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

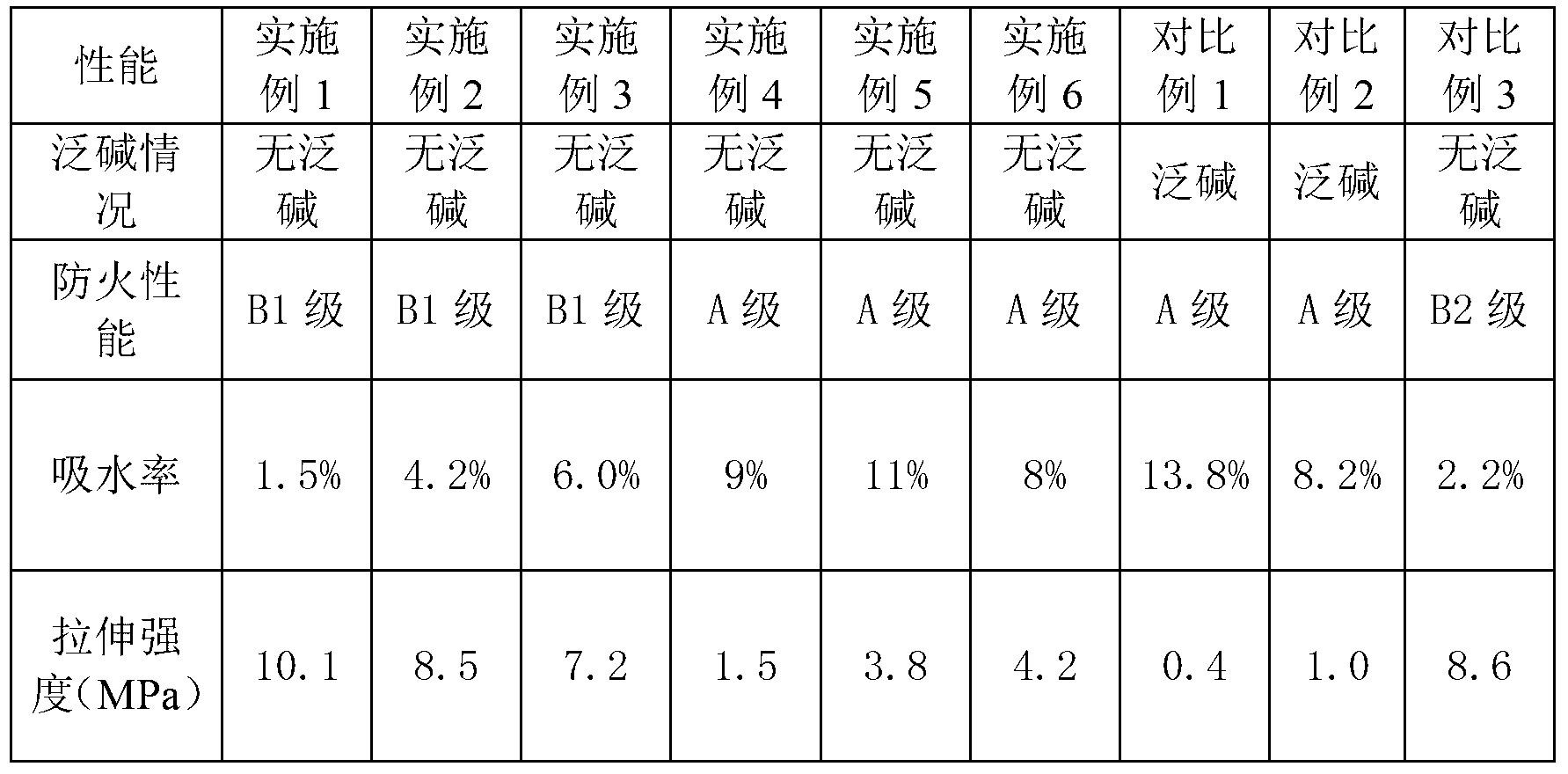

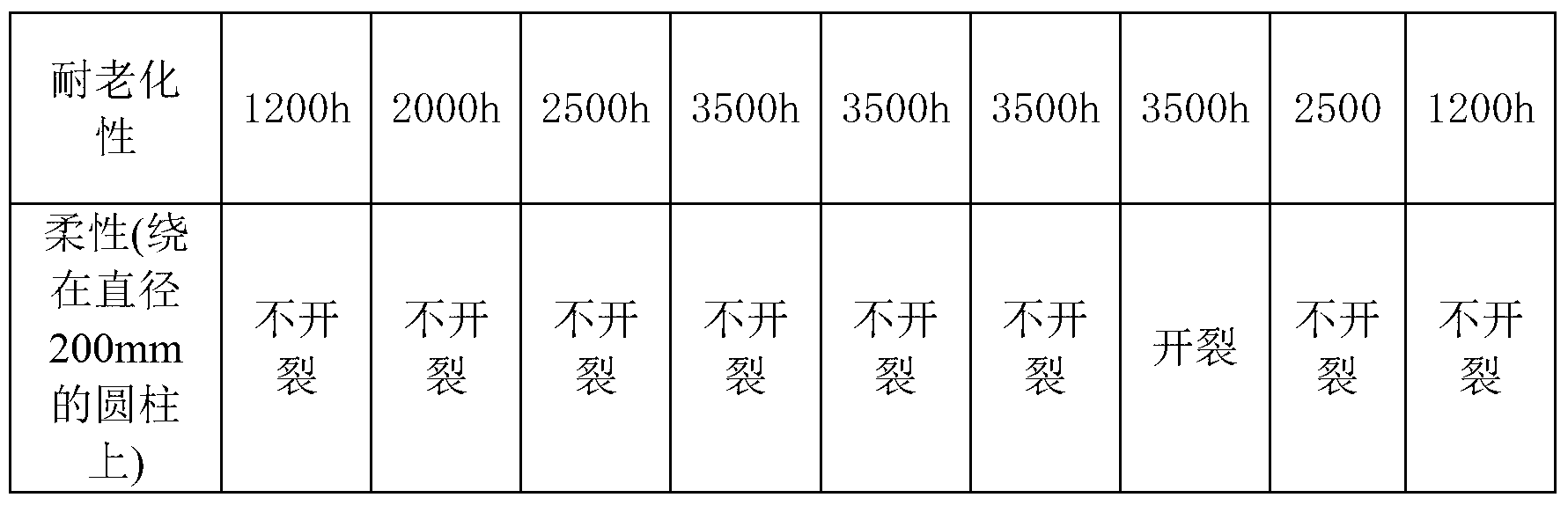

Examples

Embodiment 1

[0030] A flexible decorative sheet, its raw materials are composed of the following mass percentage components: S95 mineral powder 30%, acrylic polymer emulsion (solid content 45%) 20%, water-repellent agent (water-repellent agent produced by Dongguan Aoda Chemical Factory) B5) 0.1%, glass fiber 0.1%, and the balance is quartz sand.

[0031] The manufacturing method of the above-mentioned flexible decorative sheet comprises the following steps:

[0032] 1) Crushing the quartz sand to 100-200 meshes, mixing the pulverized quartz sand with S95 mineral powder and glass fiber to obtain a dry material;

[0033] 2) Add the water-repellent agent into water with 10% of the total weight of the raw materials, stir evenly to form a suspension, add the dry material to it, stir evenly, then add the acrylic polymer emulsion, and stir to form a uniform slurry;

[0034] 3) The slurry is extruded on a mold with wood grain, with a thickness of 3 mm, cured at 60° C. and then stripped to obtain ...

Embodiment 2

[0036] A flexible decorative sheet, its raw materials are composed of the following mass percentage components: S95 mineral powder 35%, acrylic polymer emulsion (solid content 48%) 16%, polyvinyl alcohol fiber 0.5%, water repellent (Wacker company The produced silicone water repellent 1042) is 0.2%, and the balance is stone powder.

[0037] The manufacturing method of the above-mentioned flexible decorative sheet comprises the following steps:

[0038] 1) Grinding the stone powder to 100-200 meshes, mixing the crushed stone powder with S95 mineral powder and polyvinyl alcohol fiber to obtain a dry material;

[0039] 2) Add the water-repellent agent into water with 15% of the total weight of the raw materials, stir evenly to form a suspension, add the dry material to it, stir evenly, then add the acrylic polymer emulsion, and stir to form a uniform slurry;

[0040] 3) extruding the slurry on a mold with wood grain, with a thickness of 4 mm, and removing the film after curing a...

Embodiment 3

[0042] A flexible decorative sheet, its raw materials are composed of the following mass percentage components: S105 mineral powder 40%, acrylic polymer emulsion (solid content 48%) 14%, glass fiber 1%, iron oxide red 0.5%, water repellent (Organosilicon water repellent 1042 produced by Wacker Company) 0.5%, and the balance is porcelain slag. The manufacturing method of the above-mentioned flexible decorative sheet comprises the following steps:

[0043] 1) Crush the porcelain slag to 100-200 meshes, mix the crushed porcelain slag with S105 mineral powder and glass fiber to obtain a dry material;

[0044] 2) Add the water-repellent agent into water with 20% of the total weight of the raw materials, stir evenly to form a suspension, add the dry material to it, stir evenly, then add the acrylic acid polymer emulsion, and stir to form a uniform slurry;

[0045] 3) Extrude the slurry on a mold with a cowhide texture, with a thickness of 3 mm, and release the film after curing at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com