Patents

Literature

45results about How to "Reduce ubiquitination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

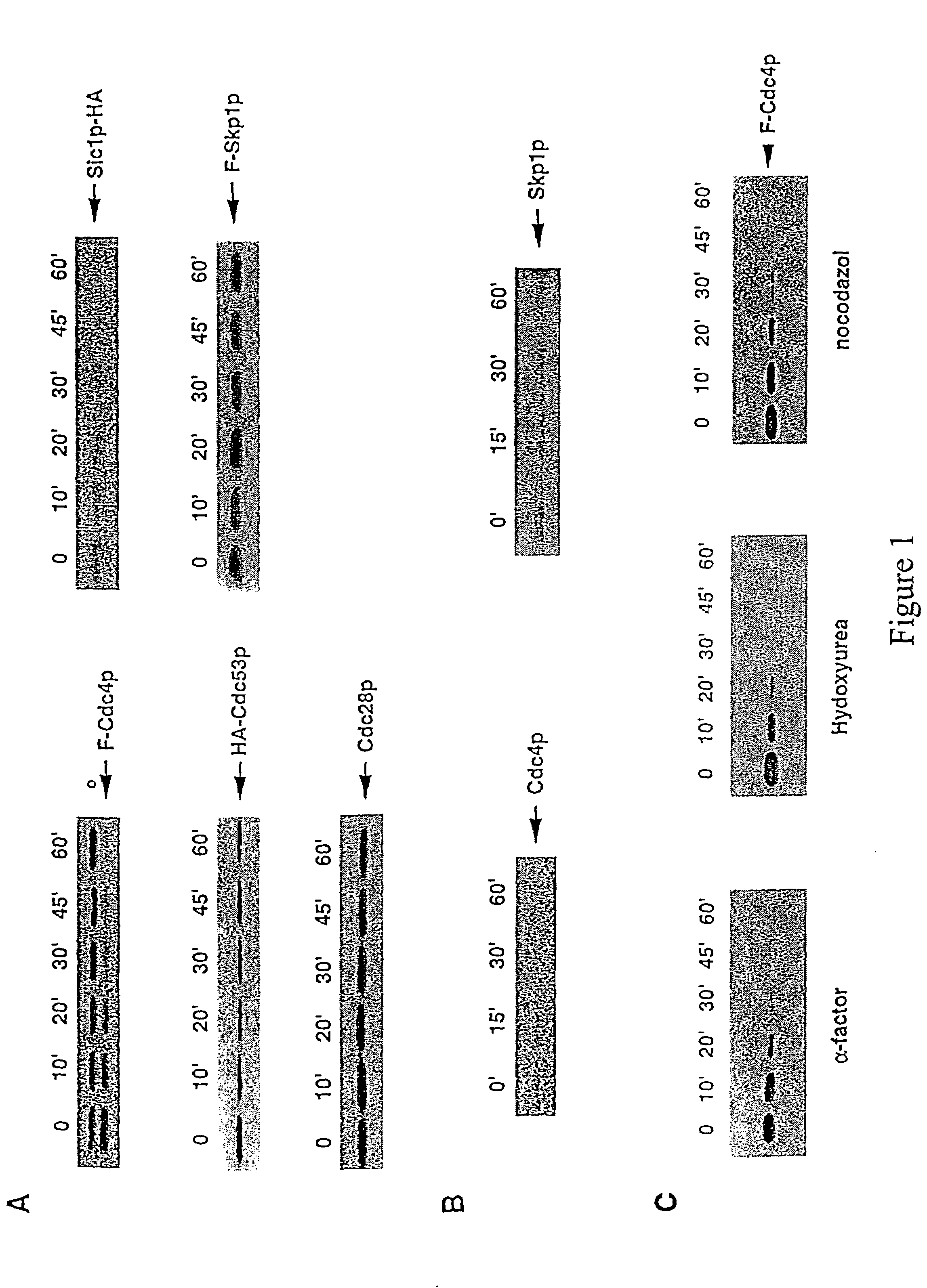

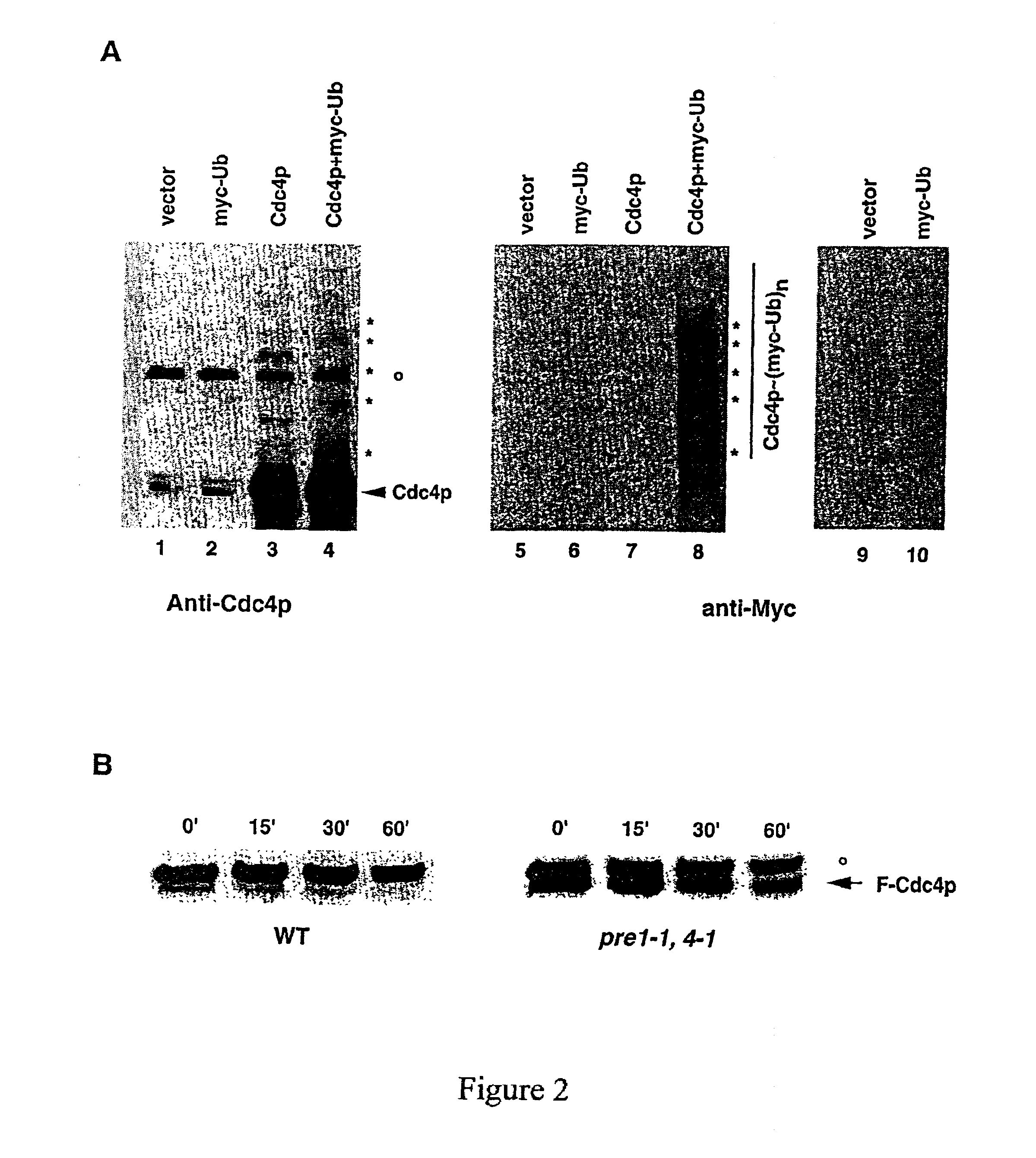

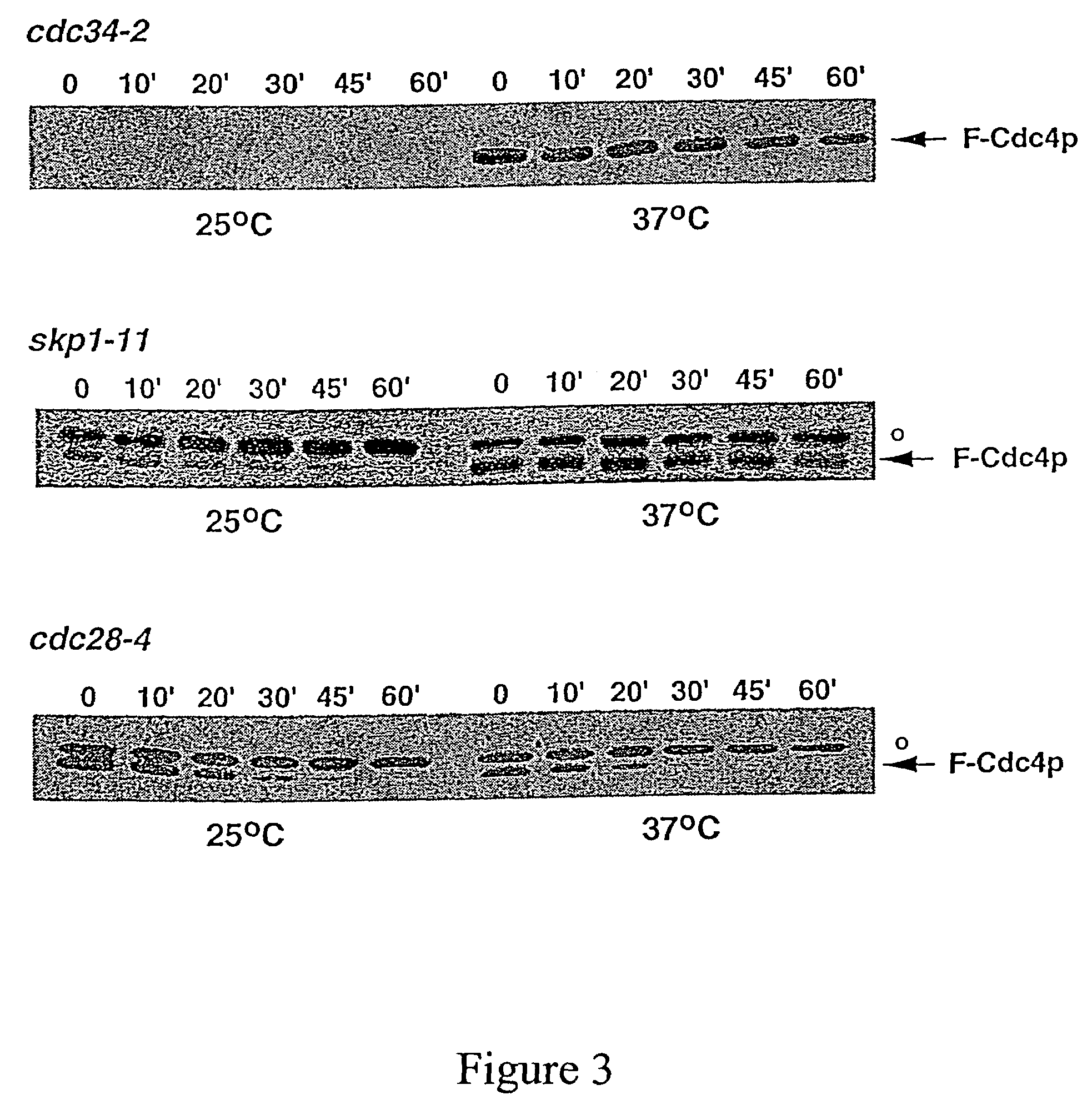

Targeted proteolysis by recruitment to ubiquitin protein ligases

InactiveUS7223556B1Decrease and increases activityReduce ubiquitinationAntibody mimetics/scaffoldsFusion with degradation motifUbiquitin-Protein LigasesProteolysis

The present invention relates to methods and reagents for targeting proteolysis of a polypeptide by cis or trans association with a ubiquitin protein ligase, and further provides methods and reagents for inhibiting the ubiquitination and proteolysis of cellular proteins which are recognized by a ubiquitin protein ligase.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

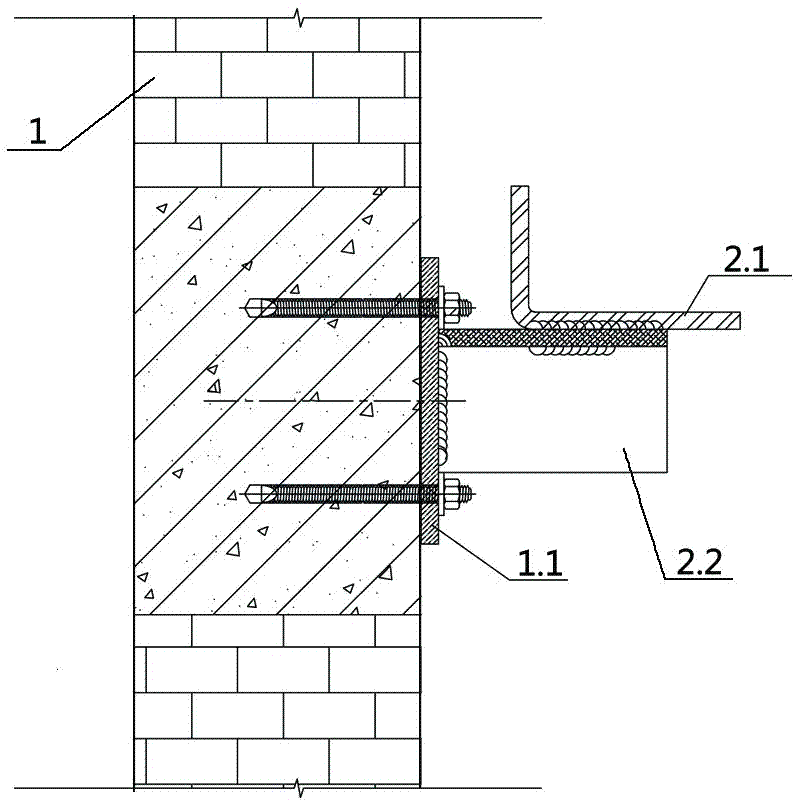

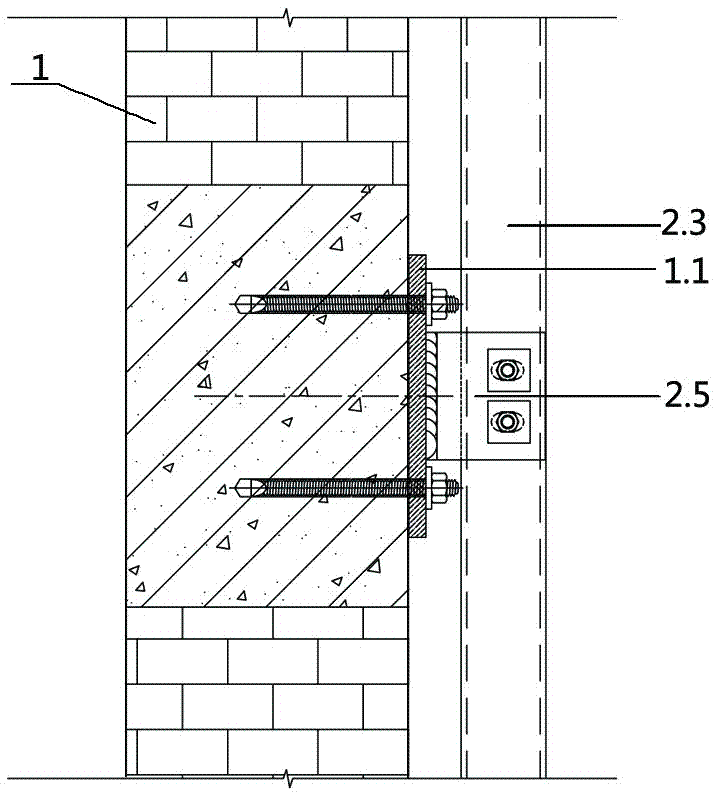

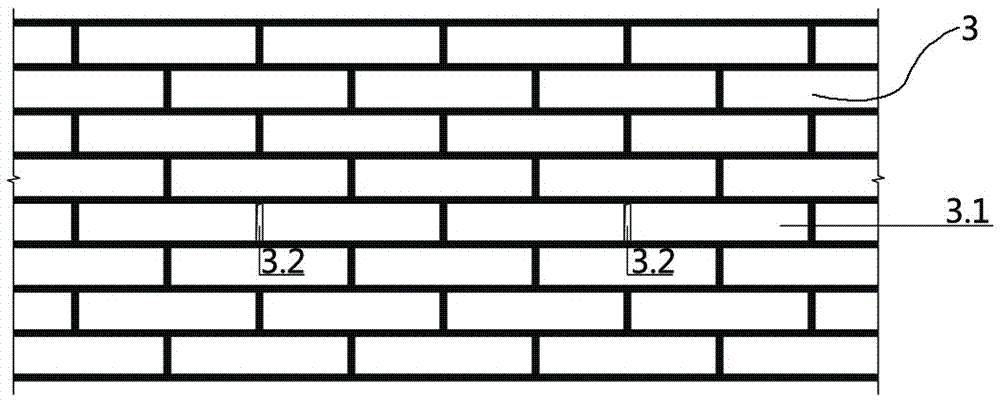

Steel structure keel masonry brick outer curtain wall system and its construction method

ActiveCN107227813ASolve the height-thickness ratioAddressing Structural StabilityWallsBrickBuilding energy

The invention provides a steel structure keel masonry brick outer curtain wall system and its construction method, wherein a curtain wall keel of the curtain wall system comprises a cross supporting angle steel arranged in a full length, and main and secondary keels; the curtain wall is a ganged brick curtain wall, and the part of the wall of which bottom part is located beneath the bottommost cross supporting angle steel is built above a main structure plate or a main structure bracket; the rest part is paved on the cross supporting angle steel; position closing to the bottom part of the curtain wall is provided with an apron flashing board with high inside and low outside; horizontal binding reinforcement meshes are staggered in the curtain wall at intervals; an air interlayer forms between the curtain wall and the main structure outer wall; part of the bottom part of the air interlayer beneath the apron flashing board is grouted by cement mortar. The masonry brick is combined with the curtain wall keel system, thus the ratio of height to thickness and the structure stability are effectively solved; the air interlayer plays the heat insulation and ventilation effects, thus the purpose of building energy-saving is saved; multiple waterproof structures are arranged so that the saltpetering of the ganged brick curtain wall and the water seepage of the main structure outer wall are reduced.

Owner:BEIJING LIUJIAN CONSTR GRP

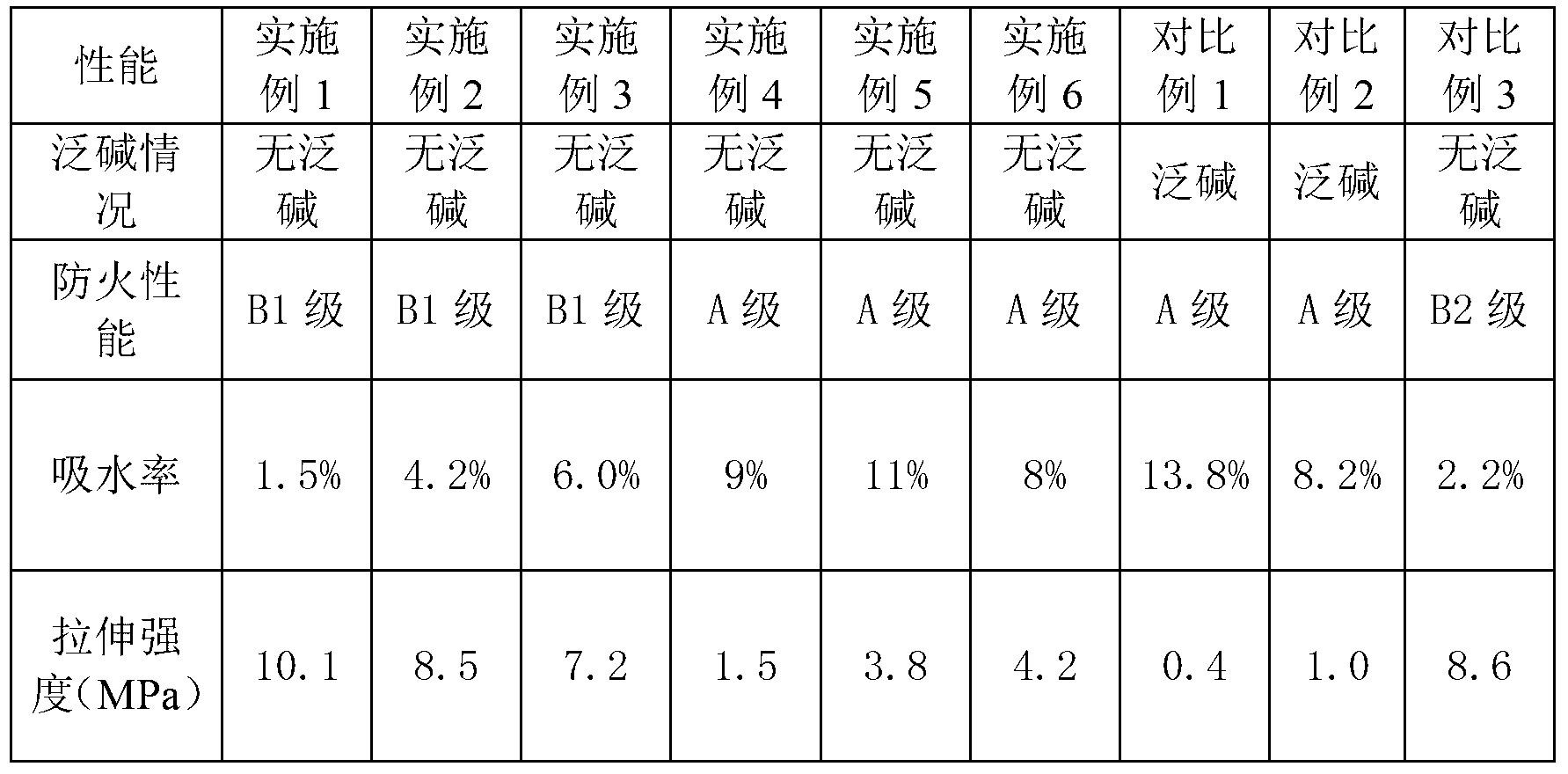

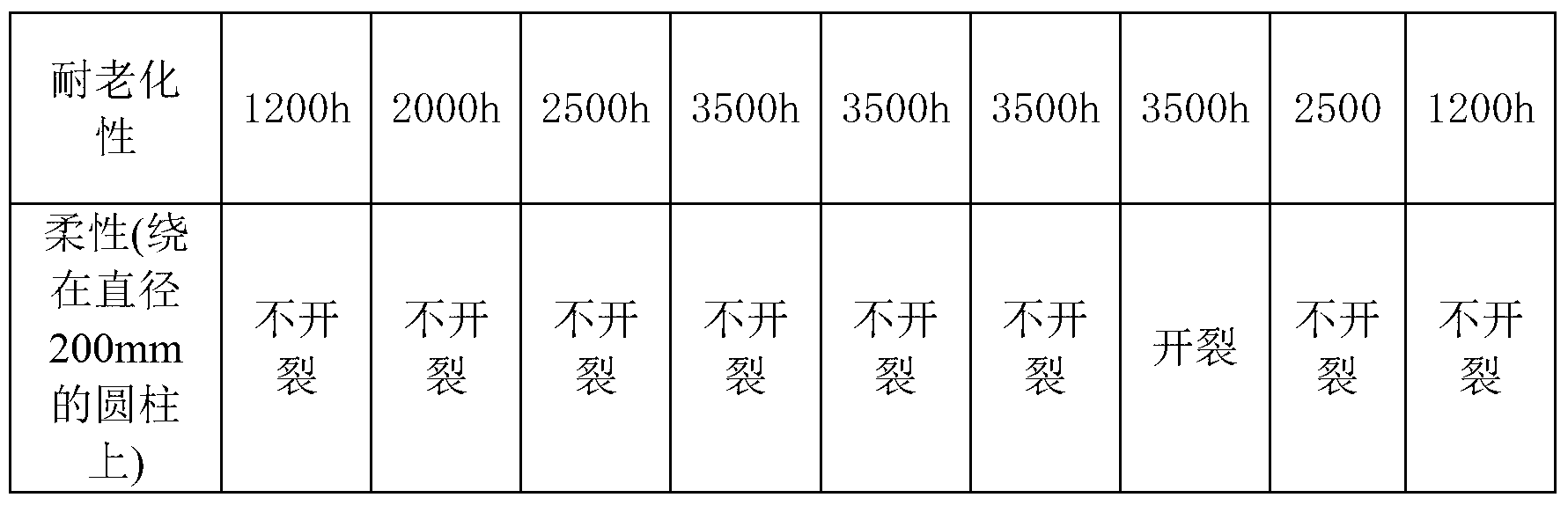

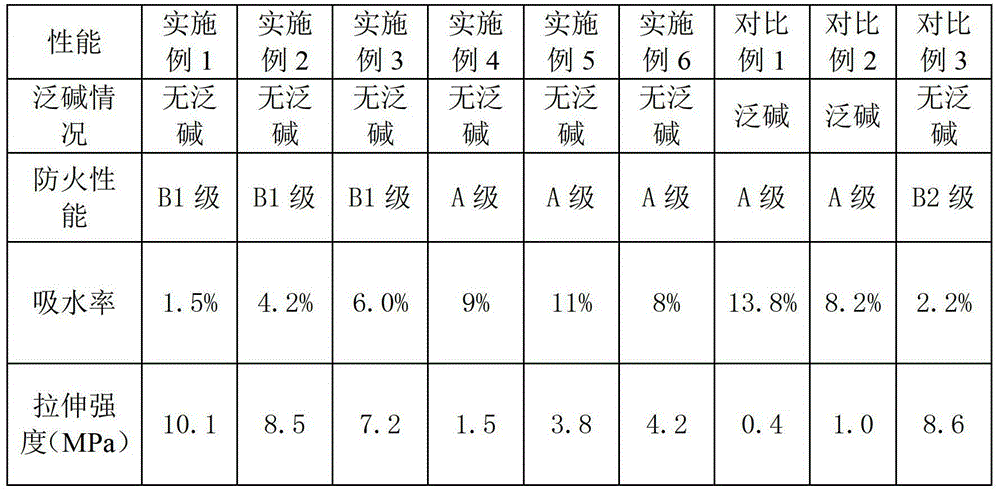

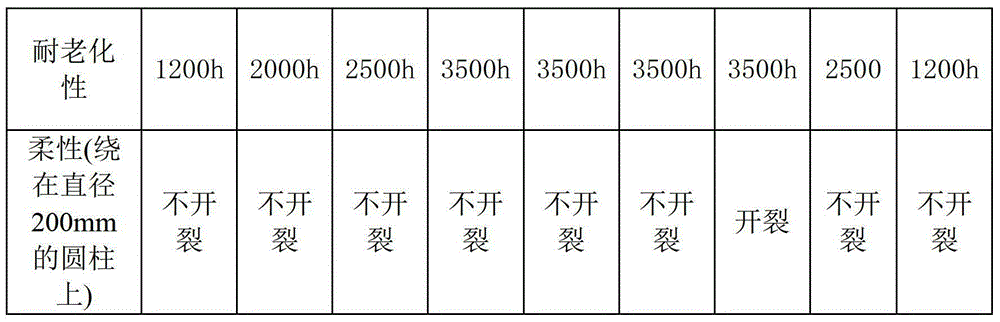

Flexible decorative sheet and manufacturing method thereof

ActiveCN103288405AHigh surface hardnessReduce the degree of polymerizationPolymer scienceAcrylic polymer

The invention discloses a flexible decorative sheet and a manufacturing method thereof. The flexible decorative sheet disclosed by the invention is composed of the following raw materials by mass percent: 30-60% of blast furnace mineral powder, 7-20% of acrylic polymer emulsion, 0.1-2% of fibre, 0.1-5% of water repellent, 0-3% of pigment, and the balance of filling material. According to the invention, the use amounts of cement and polymer emulsion are greatly reduced, so that the cost is greatly reduced; and the flexible decorative sheet disclosed by the invention has the characteristics of being excellent in ageing-resistant performance, good in fireproof performance and saltpetering-resistant.

Owner:GUANGXI PHOMI MCM CO LTD

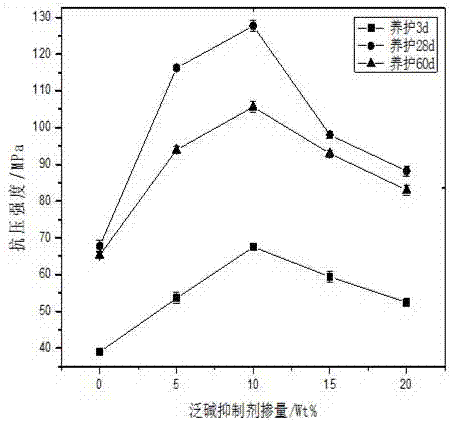

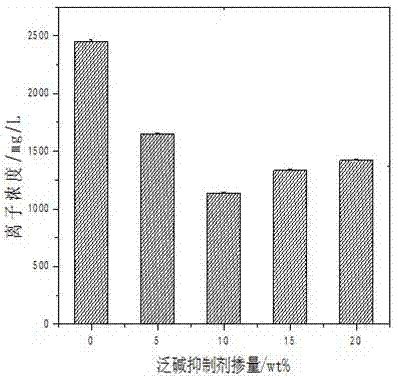

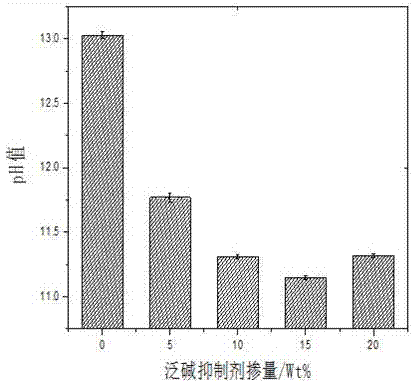

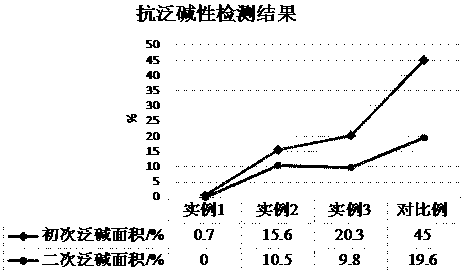

Alkali-activated slag cement efflorescence inhibitor and preparation method thereof

The invention relates to the technical field of building materials, in particular to an inhibitor capable of inhibiting efflorescence of alkali-activated slag cement and adjusting the performance of the alkali-activated slag cement, and a preparation method of the inhibitor. The alkali-activated slag cement efflorescence inhibitor is characterized by being prepared from the following raw materials by mass percent: 10-30% of zeolite, 10-20% of silica fume, 20-30% of pulverized fuel ash, 5-15% of boric acid and 5-55% of superfine slag powder. The alkali-activated slag cement efflorescence inhibitor provided by the invention is simple to prepare and use, and has a certain retarding effect; after the efflorescence inhibitor is added into alkali-activated slag cement concrete and mortar, the working performance of the alkali-activated slag cement concrete and mortar can be improved, the engineering quality is improved after construction, the early strength and later strength of the alkali-activated slag cement concrete can be increased by 15-20%, the efflorescence probability of the alkali-activated slag cement concrete is greatly reduced, and the reduction magnitude reaches up to 80%; the alkali-activated slag cement efflorescence inhibitor can inhibit the efflorescence phenomenon of the alkali-activated slag cement after construction, and has an inhibiting effect on the efflorescence phenomenon of the building materials after construction.

Owner:UNIV OF JINAN

Weather-resistant high-strength environment-friendly antique-imitation brick and preparation method thereof

The invention discloses a weather-resistant high-strength environment-friendly antique-imitation brick. The weather-resistant high-strength environment-friendly antique-imitation brick is prepared from the following raw materials in parts by weight: 10-20 parts of blue stone powder, 3-7 parts of antique-imitation auxiliaries, 7-9 parts of blast-furnace slag, 5-7 parts of steel slag, 4-8 parts of coal gangue, 10-14 parts of purified landfill, 8-12 parts of waterproof latex, 6-8 parts of tackifying additives, 13-15 parts of ore powder, 10-14 parts of fine sand and 7-11 parts of silicate cement. The environment-friendly antique-imitation brick disclosed by the invention has excellent performance in imperviousness, corrosion resistance and freeze-thaw resistance, the compression strength is relatively high, the appearance is pure in color and full in antique tone, and the environment-friendly antique-imitation brick has a realistic effect when the environment-friendly antique-imitation brick is applied to the repair or imitation of antique buildings; meanwhile, by adopting a large amount of industrial and agricultural wastes, the resources are saved, the cost is reduced, the raw materials are readily available, the process is simple, and the environmental hazards are effectively reduced, so that the preparation method disclosed by the invention has a relatively high practical value and a good application prospect.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

Parapet construction method

PendingCN109914645AReduces instances of leaky efflorescenceIncreased durabilityWallsRoof covering insulationsBrickWater leakage

The invention relates to the field of building construction, and provides a parapet construction method aiming at the problem that water seepage and saltpetering easily occur at the joint of a parapetand a roof. The method comprises the following steps: S1, reserving a groove: reserving the groove for building a parapet at the top of a house; S2, constructing a injecting waterproof concreteinto the groove reserved in the step S1, and piling up wall bricks at the bottommost layer of the parapet before the concrete begins to solidify, so as to enable the wall bricks arranged in the groove to be partially soaked in the waterproof concrete; S3, piling up the parapet: piling up residual wall bricks of the parapet; S4, painting an exterior wall: painting a layer of waterproof concrete outside the wall body; and S5, smearing a waterproof layer: applying a waterproof layer outside the waterproof concrete layer through coating. The waterproof concrete is poured into the groove reservedin the roof at first, and then the base layer of the parapet is built in the waterproof concrete, so that a gap is not likely to exist between the base layer of the parapet and the roof, and the situation that water leakage and salfpetering are likely to happen at the joint of the parapet and a house is reduced.

Owner:GUANGZHOU NO 4 DECORATION CO LTD

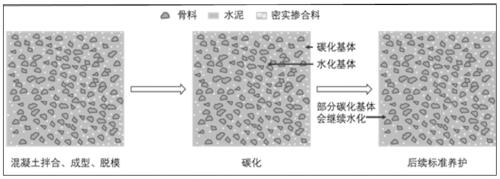

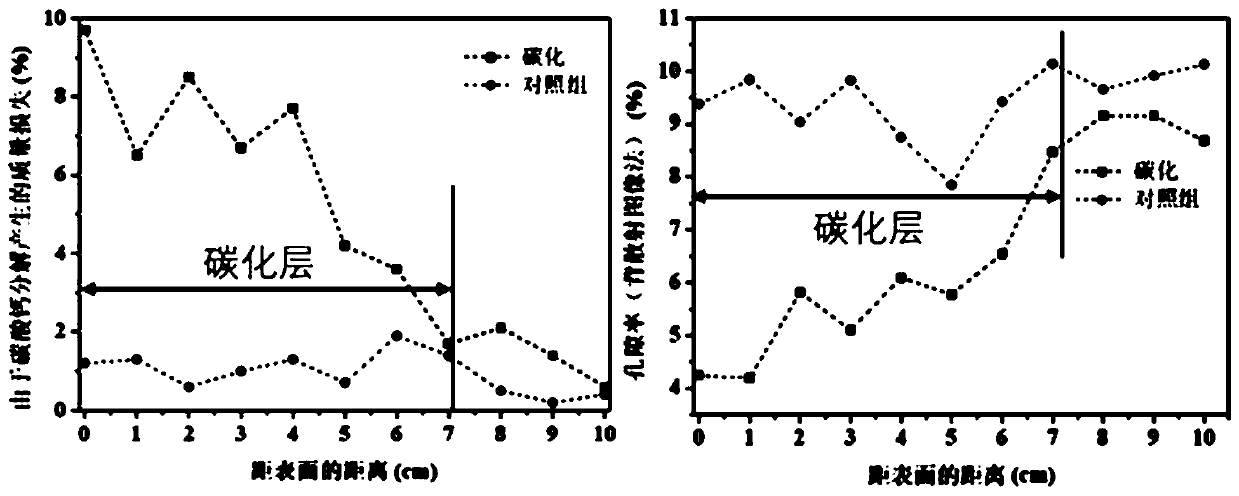

High-durability concrete product with gradient structure, and preparation method thereof

ActiveCN109694224AImprove ion erosion resistanceReduce ubiquitinationCarbonizationUltimate tensile strength

The invention relates to a high-durability concrete product with a gradient structure, and a preparation method thereof. The preparation method comprises the following steps: 1) mixing for obtaining concrete: mixing a dense admixture for substituting a part of a cementing material to obtain the concrete; 2) pouring the concrete into a mold, molding the concrete, and curing and demolding the moldedconcrete to obtain a concrete test piece; and 3) drying the surface of the concrete test piece, carrying out carbonization curing on the dried concrete test piece in an autoclave in a carbon dioxideatmosphere, and then carrying out standard curing to obtain the high-durability concrete product with the gradient structure. The gradient structure which gradually densifies from the inside to the outside is formed on the surface of the concrete test piece through the carbonization curing treatment, and the surface carbonized dense layer can improve the corrosion resistance of the concrete material and prolong the service life; and the outer layer has a high strength, so the confinement effect is formed, thereby the deformation resistance of the test piece is improved, and the hardening of the concrete test piece is accelerated.

Owner:WUHAN UNIV OF TECH

Efficient gap filler

InactiveCN106810146AReduce ubiquitinationInhibition of ubiquitinationSolid waste managementHydroxypropylmethyl cellulosePolypropylene

The invention relates to the field of buildings and particularly relates to an efficient gap filler. The efficient gap filler is prepared from the following substances in parts by weight: 35-45 parts of cement, 15-20 parts of quartz sand, 20-30 parts of washed-out sand, 8-15 parts of pulverized coal ash, 15-25 parts of redispersible organosilicone powder, 5-8 parts of inorganic pigment, 5-8 parts of hydroxyethyl methyl cellulose ether, 0.5-1.5 parts of water reducer, 0.8-1.5 parts of setting retarder, 10-15 parts of zinc chloride, 0.5-1.2 parts of redispersible latex powder, 5-10 parts of heavy calcium carbonate powder, 10-15 parts of polypropylene staple fibers, 1.5-3 parts of hydroxypropyl methylcellulose, 0.8-2.1 parts of mildew preventive, 0.8-2.0 parts of citric acid and 15-30 parts of vitrified micro bubbles. According to the efficient tile gap filler provided by the invention, the low-alkali cement is adopted as a raw material, so that the occurrence of an efforescence phenomenon can be relieved; the added citric acid can be used for effectively inhibiting the occurrence of the efforescence phenomenon; the added water reducer and setting retarder can be used for prolonging the service time of the gap filler, maintaining balance and improving viscosity; and the added vitrified micro bubbles can be used for improving warm-keeping and heat-insulating performance of the gap filler.

Owner:青岛城轨交通装备科技有限公司

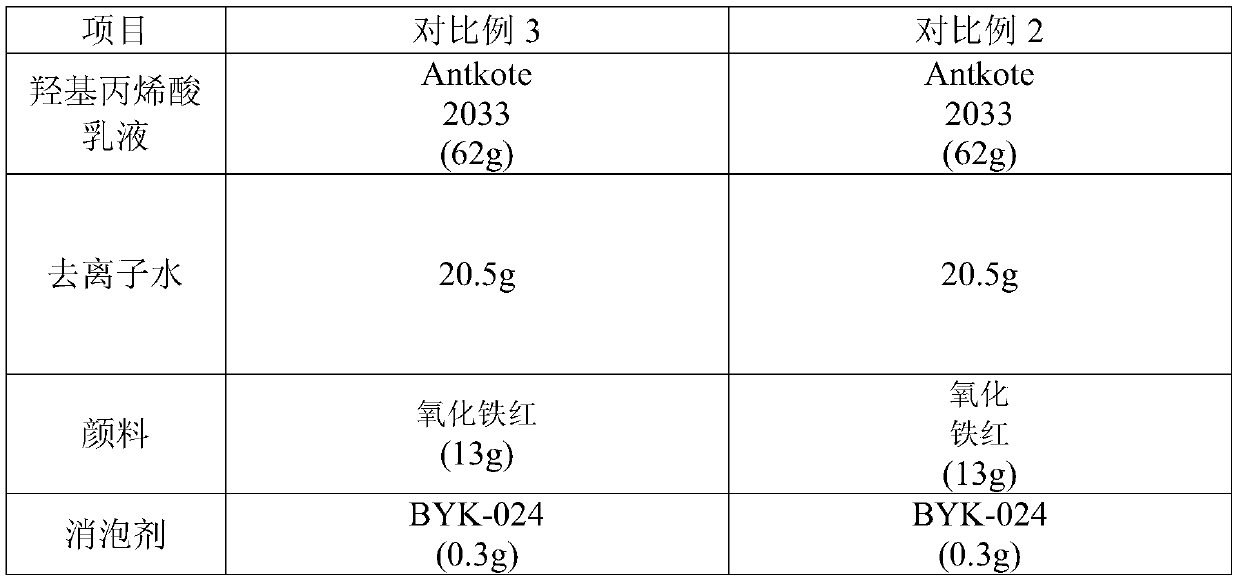

Mortar without visible alkali efflorescence

InactiveCN105731945AReduce porosityReduce generationSolid waste managementCelluloseShrinkage cracking

The invention discloses mortar without visible alkali efflorescence. The mortar comprises, by weight, 20-40% of cement, 5-10% of coal ash, 30-60% of quartz sand, 2-5% of emulsion, 0.01-0.05% of cellulose ether, 0.1-0.5% of water reducing agents, 0-0.1% of retarders, 10-20% of water and 0-0.01% of defoaming agents. The mortar without the visible alkali efflorescence has the advantages that the mortar is free of the visible alkali efflorescence and dry-shrinkage cracking, short in curing time, good in weather fastness and harmless to environments and human bodies, and is rigid and flexible.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

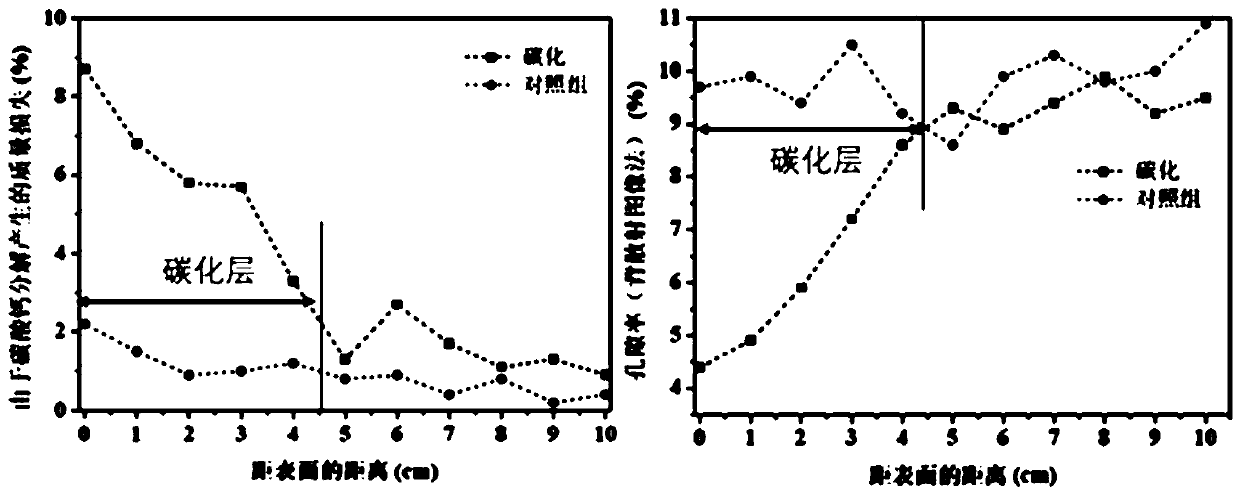

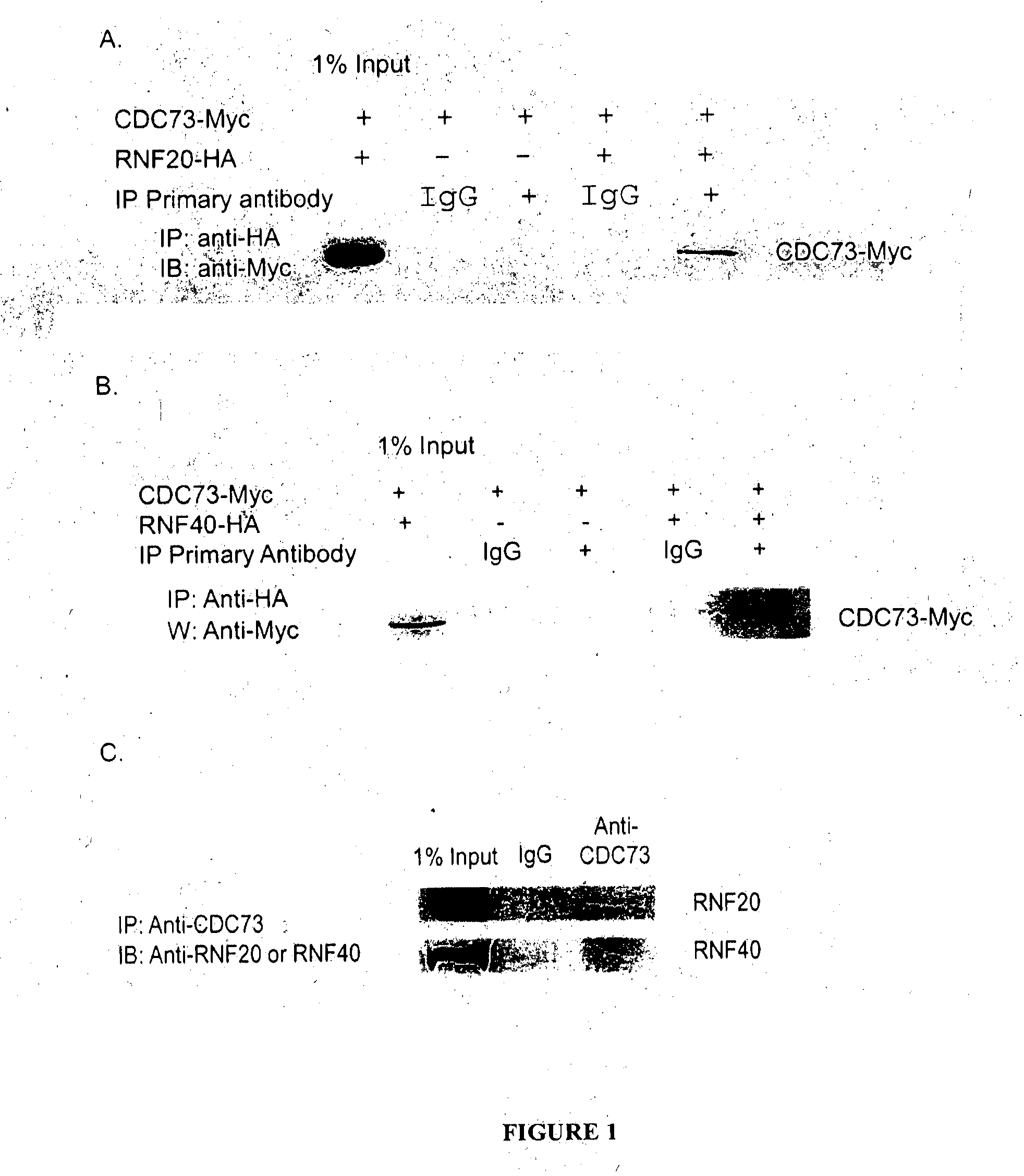

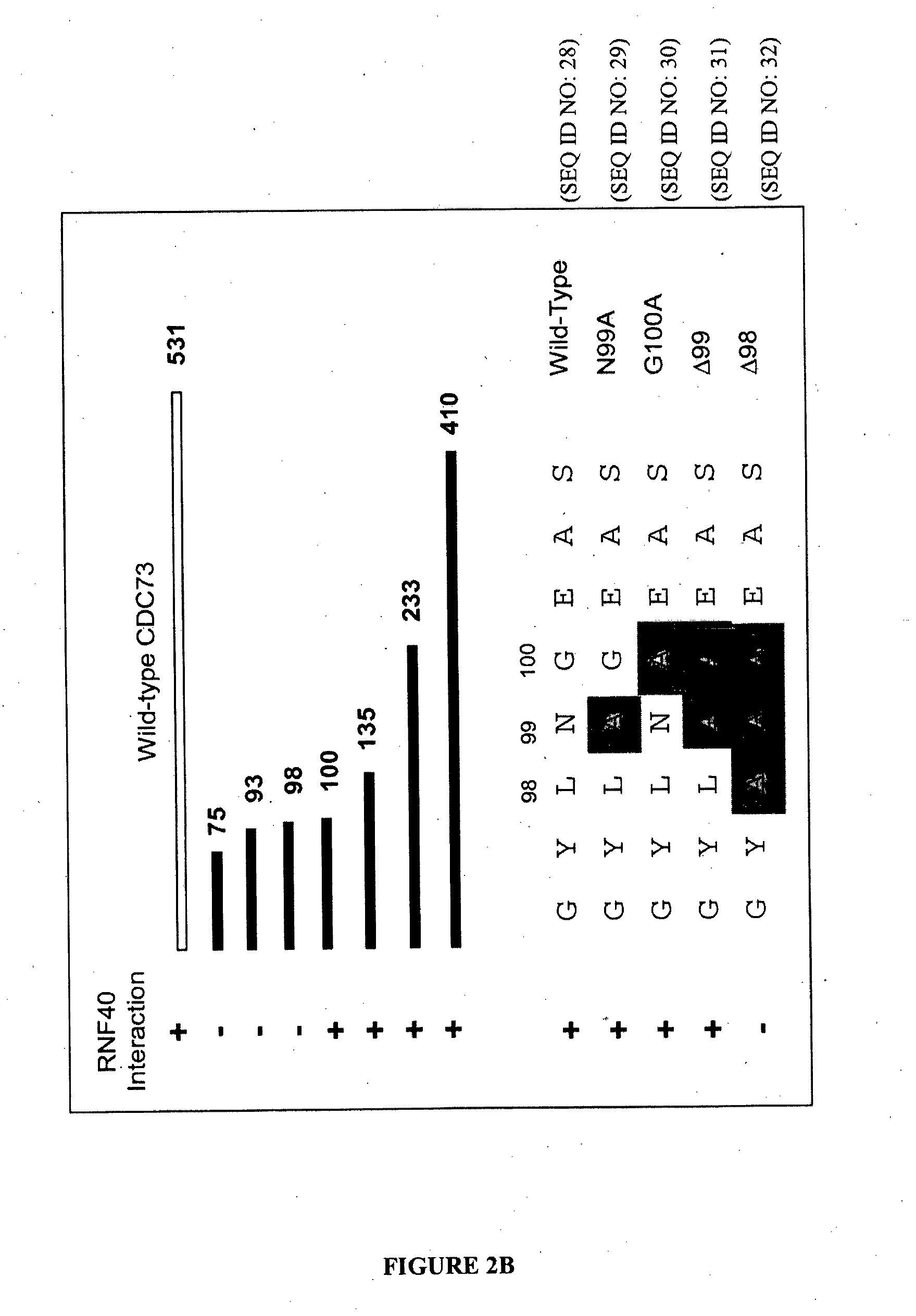

Histone protein ubiquitination as a cancer biomarker

InactiveUS20130295584A1Increase gene expressionUbiquitination of histone proteins could be increasedCompound screeningApoptosis detectionTumor BiomarkersCancers diagnosis

The present disclosure relates generally to the field of cancer diagnosis. More specifically, the present disclosure relates to the identification and use of monoubiquitination of histone 2B as a biomarker for the diagnosis and prognosis of cancer including, but not limited to, parathyroid cancer. The present disclosure also relates to the identification of binding between CDC73 and RNF20, and the use of CDC73 and RNF20 in an assay for screening for an agent that modulates monoubiquitination of a histone protein.

Owner:NORTHERN SYDNEY LOCAL HEALTH DISTRICT A ESTABLISHED PURSUANT TO THE HEALTH SERVICES ACT 1997 NSW

Pavement concrete for municipal construction engineering

The invention discloses pavement concrete for municipal construction engineering. The pavement concrete comprises the following raw materials in parts by weight: 40-50 parts of cement, 10-15 parts ofdiatomite, 5-10 parts of glycerol monostearate, 3-5 parts of sodium monofluorophosphate, 3-5 parts of sodium alginate, 6-8 parts of a water reducing agent, 10-15 parts of an expansion fiber anti-cracking waterproof agent, 3-5 parts of amorphous dodecacalcium heptaaluminate, 4-6 parts of a silane coupling agent, 1-2 parts of vaseline, 4-6 parts of an acrylic emulsion, 1-2 parts of fatty alcohol-polyoxyethylene ether, 1-2 parts of an antifoaming agent and 30-40 parts of water. Compared with the prior art, the pavement concrete has advantages that: by adding the diatomite and the diatomite withinthe particle size range of 3-12 microns, the phenomenon that cracks are found in concrete can be well avoided, and the strength of the concrete is improved; the glycerol monostearate can improve strength of the concrete. In conclusion, the pavement concrete for municipal construction engineering prepared by the scheme has the performance advantages of high toughness, impact resistance, crack resistance, wear resistance, skid resistance and the like.

Owner:安徽虹达道路桥梁工程有限公司

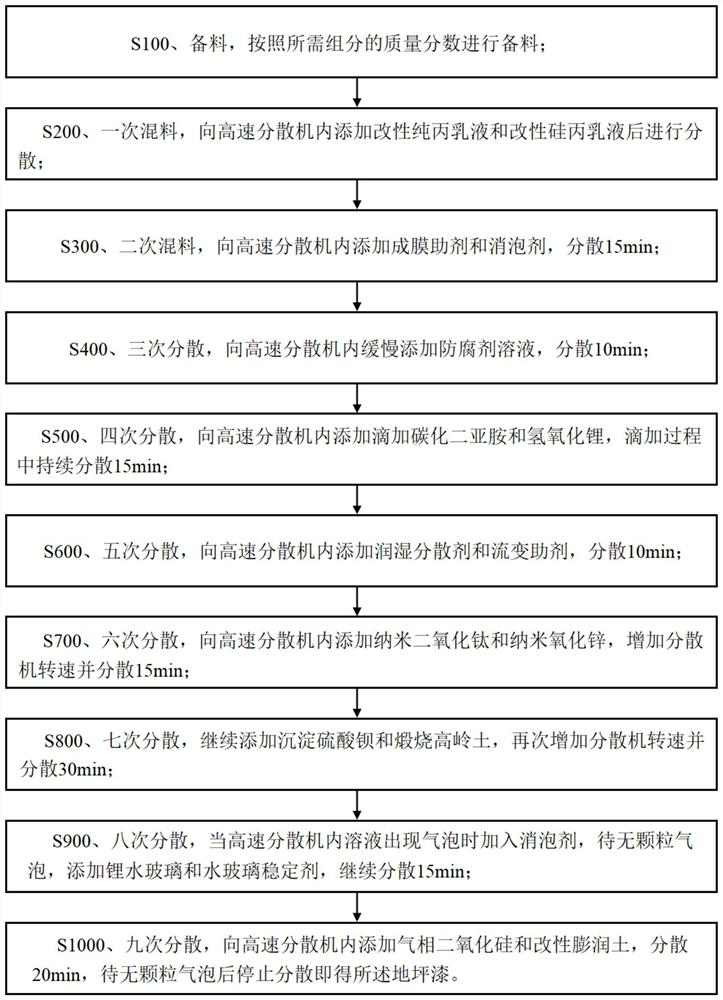

Single-component waterproof high-hardness water-based floor paint and preparation method thereof

InactiveCN111647329AFacilitate cross-linkingSolve the problem of storage stabilityAlkali metal silicate coatingsWeather resistanceEmulsion

The invention relates to single-component waterproof high-hardness water-based floor paint and a preparation method thereof. With the combination of a modified pure acrylic emulsion and a modified silicone acrylic emulsion, not only can the weather resistance be improved, but also certain hardness can be enhanced; a good waterproof effect is also achieved; secondly, polycarbodiimide is also introduced into the formula, so that emulsion crosslinking is effectively promoted, drying rate is accelerated, and adhesive force is improved; and thirdly, the materials are different from sodium silicateor potassium silicate used by common floor paint. The lithium silicate adopted by the invention has the advantages that the modulus is 3.5, the possibility of efflorescence is reduced to the maximum extent, the stability is better, and most importantly, the overall strength and wear resistance are improved. And finally, in order to solve the problem of storage stability of a traditional silicate system, the water glass stability is introduced, so that the reaction of the water glass and the emulsion can be effectively prevented, the coexistence effect is achieved, and the problem of storage stability of the system is effectively solved.

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

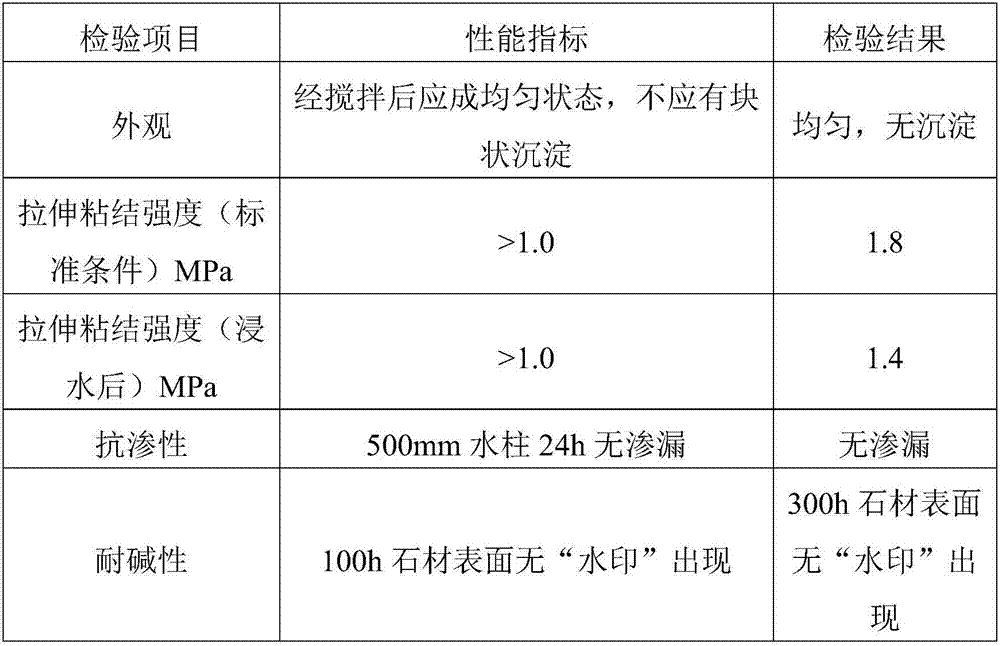

Safe and environment-friendly type natural stone waterproof alkali-resistant backing adhesive and preparation method thereof

InactiveCN106905898AHigh bond strengthImprove water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPowder mixtureEmulsion

The invention relates to a safe and environment-friendly type natural stone waterproof alkali-resistant backing adhesive and a preparation method of the safe and environment-friendly type natural stone waterproof alkali-resistant backing adhesive. The backing adhesive comprises the following components by weight: 4-6 parts of liquid mixture and 4-6 parts of powder mixture, the liquid mixture comprises the following components by weight: 380-420 parts of acrylic emulsion, 95-105 parts of lithium silicate aqueous solution, 1-3 parts of sterilizing agent, 1-3 parts of defoaming agent, and 450-550 parts of water, the powder mixture comprises the following components by weight: 430-480 parts of kaolin, 280-320 parts of heavy calcium carbonate powder, 230-270 parts of snowflake white powder, 1-3 parts of water reducing agent, and 1-3 parts of cellulose; and the various components in the powder mixture are respectively added into the liquid mixture in the preparation process. Compared with the prior art, the lithium silicate aqueous solution and the acrylic emulsion are compounded, the kaolin, the heavy calcium carbonate powder and the snowflake white powder are used as powder materials, the prepared backing adhesive is high in bonding strength, water resistance and alkali resistance, the phenomena of efflorescence, saltpetering and water spotting of the natural stone are solved fundamentally, and the backing adhesive is safe and environment-friendly.

Owner:BNSA NEW MATERIAL SHANGHAI CO LTD

Flexible decorative sheet and manufacturing method thereof

The invention discloses a flexible decorative sheet and a manufacturing method thereof. The flexible decorative sheet disclosed by the invention is composed of the following raw materials by mass percent: 30-60% of blast furnace mineral powder, 7-20% of acrylic polymer emulsion, 0.1-2% of fibre, 0.1-5% of water repellent, 0-3% of pigment, and the balance of filling material. According to the invention, the use amounts of cement and polymer emulsion are greatly reduced, so that the cost is greatly reduced; and the flexible decorative sheet disclosed by the invention has the characteristics of being excellent in ageing-resistant performance, good in fireproof performance and saltpetering-resistant.

Owner:GUANGXI PHOMI MCM CO LTD

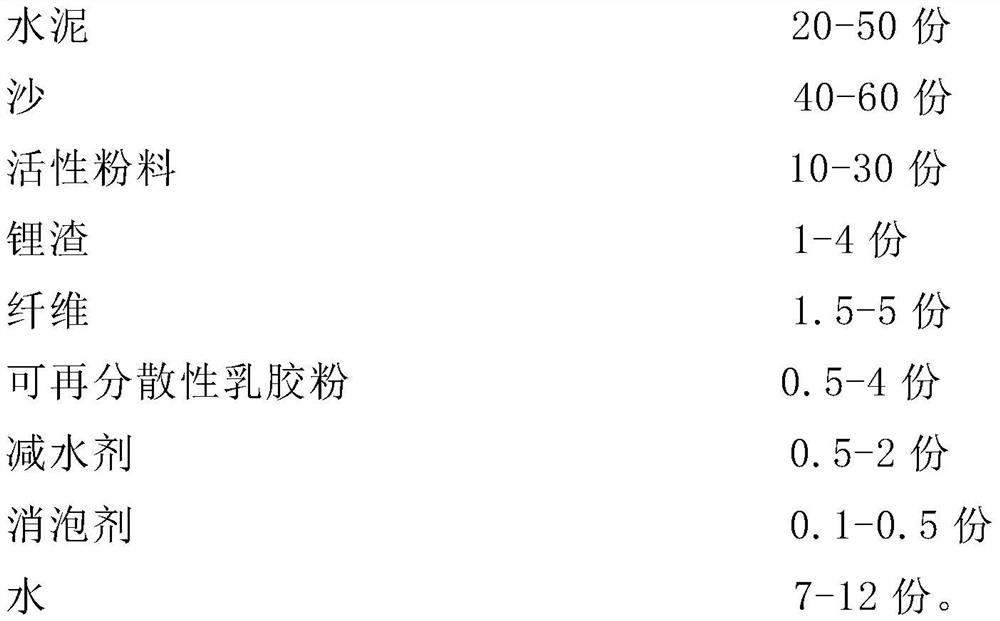

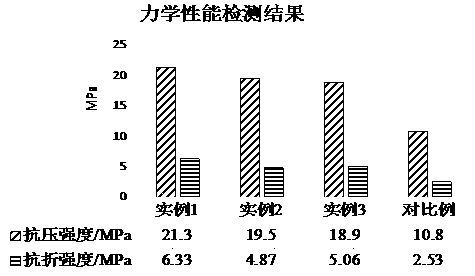

Lithium slag modified ultra-high performance concrete product and preparation method thereof

The invention discloses a lithium slag modified ultra-high performance concrete product and a preparation method thereof, wherein the lithium slag modified ultra-high performance concrete product is aflat plate or hyperboloid member with a thickness of 15-50 mm, and comprises the components: cement, sand, active powder, lithium slag, fibers, redispersible latex powder, a water reducing agent, anantifoaming agent and water. The lithium slag is pretreated by adopting the dispersible latex powder, and the hydrophobicity of organic groups is utilized, so the water absorption of the lithium slagin the concrete stirring process is reduced; then, the dispersible latex powder is dispersed when meeting water, moisture enters the pores of the lithium slag, so a free water reserve is formed, the water retention effect is achieved, and evaporation of water is reduced; the water retention effect can also be achieved through redispersion and film formation of the redispersible latex powder, early-stage dehydration shrinkage and deformation of an ultra-high performance concrete product are reduced, and meanwhile the synergistic effect of the lithium slag and other active components on the mechanical property of the ultra-high performance concrete is achieved.

Owner:深圳市汉工造技术有限公司

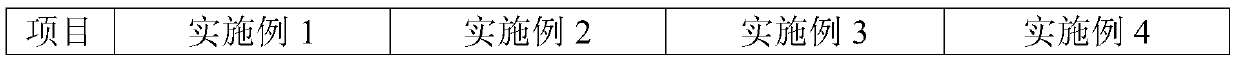

Water-based alkali-resistant water-permeable floor paint and preparation method thereof

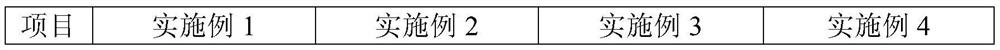

ActiveCN109749604AHigh hardnessImprove wear resistanceAntifouling/underwater paintsPaints with biocidesWater basedAlcohol

The invention discloses water-based alkali-resistant water-permeable floor paint and a preparation method thereof, and belongs to the technical field of paint. The paint is prepared by a component A and a component B, wherein the component A is formed by hydroxyl acrylic emulsion, deionized water, pigment, a defoamer, a wetting agent, a dispersant, an anti-settling agent and an inorganic alkali-resistant auxiliary and the like; and the component B is formed by a water-based aliphatic isocyanate curing agent, an alcohol ether solvent and a dehydrating agent. The water-based alkali-resistant water-permeable floor paint is capable of effectively solving a problem that a color water-permeable floor is easy to 'whiskering', and using a water-based paint system, and environment-friendly. In addition, the water-based alkali-resistant water-permeable floor paint has the characteristics of high surface strength, graded broken stone falling prevention, convenient production and the like.

Owner:NANJING CHANGJIANG PAINT

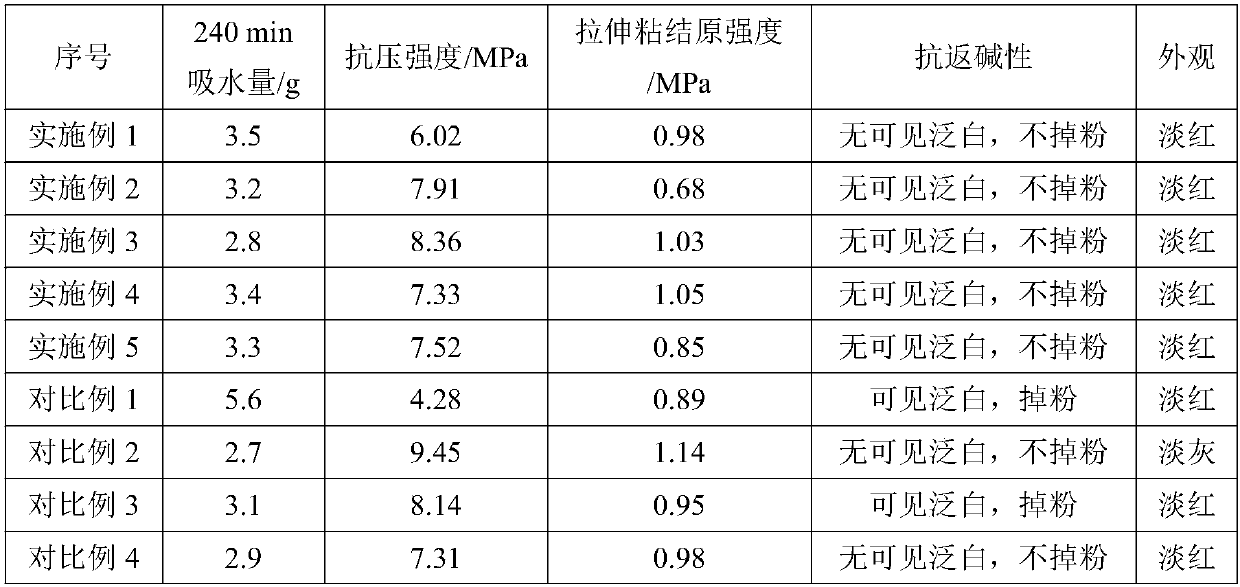

Environmentally-friendly and fadeless red decorative finish mortar

PendingCN107602059AReduce ubiquitinationImproves bonding properties and water resistanceRiver sandPortland cement

The invention belongs to the technical field of building materials, and discloses an environmentally-friendly and fadeless red decorative finish mortar. The mortar comprises, by weight, 40-50 parts ofwhite Portland cement, 1-3 parts of phosphoaluminate cement, 20-30 parts of calcined gangue powder, 3-8 parts of redisperable latex powder, 1-5 parts of nano-silica, 0.1-2 parts of a rheological thickener, 0.5-1 part of a water reducer, 0.5-1.5 parts of a water repellent, 0.2-0.8 part of a reinforcing agent, 0.1-1 part of a wetting dispersant, 0.01-0.05 part of an antifoaming agent, 0.1-0.5 partof phytic acid and 80-100 parts of washed river sands. All above components have synergistic effects, so the obtained decorative finish mortar has the advantages of no saltpetering, no color difference and good mechanical properties.

Owner:HUNAN QIWEI TECH CO LTD

A kind of preparation method of tile grout

Owner:广东亿固壁安粘贴技术有限公司

Composite cement-based anti-frosting tile binder

The invention discloses a composite cement-based anti-frosting tile binder, and belongs to the technical field of inorganic adhesives. A preparation method of the binder comprises the following steps:successively weighing in parts by weight: 45-55 parts of cement, 50-60 parts of sand, 5-6 parts of a water-retaining agent, 10-12 parts of epoxy soybean oil, 3-6 parts of a surfactant, 5-6 parts of ametal salt powder, 13-22 parts of an additive, and 9-16 parts of a modified microsphere, mixing cement and sand in a mixer, successively adding the water-retaining agent, epoxy soybean oil, the surfactant, the metal salt powder, the additive and the modified microsphere into the mixer, and performing stirring and mixing for 30-60 min at a temperature of 30-40 DEG C and a rotation speed of 300-400r / min to obtain the composite cement-based anti-frosting tile binder. The composite cement-based anti-frosting tile binder prepared by the technical scheme has excellent anti-frosting performance andbonding strength, and has broad prospects in the development of inorganic adhesive technology industry.

Owner:宋昆昆

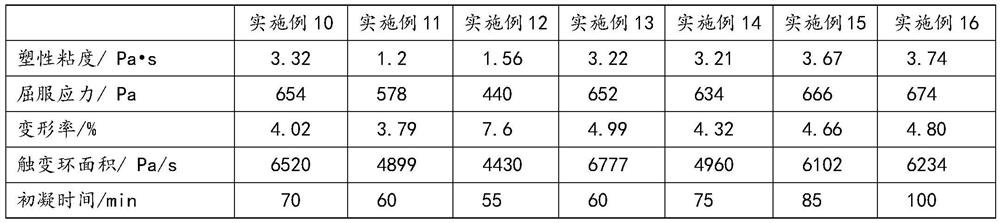

A coloring agent suitable for 3D printing white cement-based materials and its use and application

The invention belongs to the technical field of building materials, and in particular relates to a colorant suitable for 3D printing white cement-based materials and its use method and application. In parts by weight, the colorant is compounded from the following components: 1-5 parts of coupling agent, 5-30 parts of polymer emulsion, 5-30 parts of resin, 10-40 parts of mineral admixture, pigment 5-25 parts, 5-30 parts coagulant, 2-9 parts water reducer, 0.05-1.10 parts defoamer, 95-120 parts water. The coloring agent proposed by the present invention has good colorability, weather resistance, pan-alkali resistance, plastic viscosity, yield stress, fast and stable setting time, and the printed object has a low deformation rate, etc., which can well meet the requirements of 3D printing needs of white cement-based materials.

Owner:UNIV OF JINAN

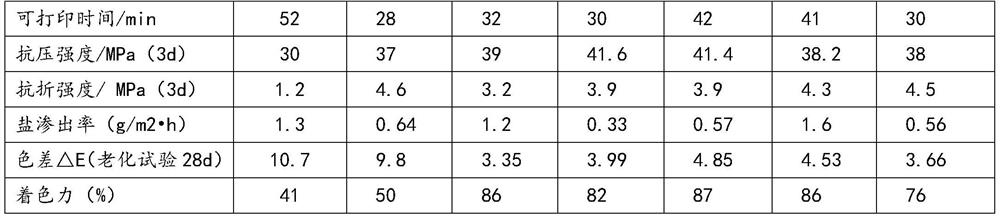

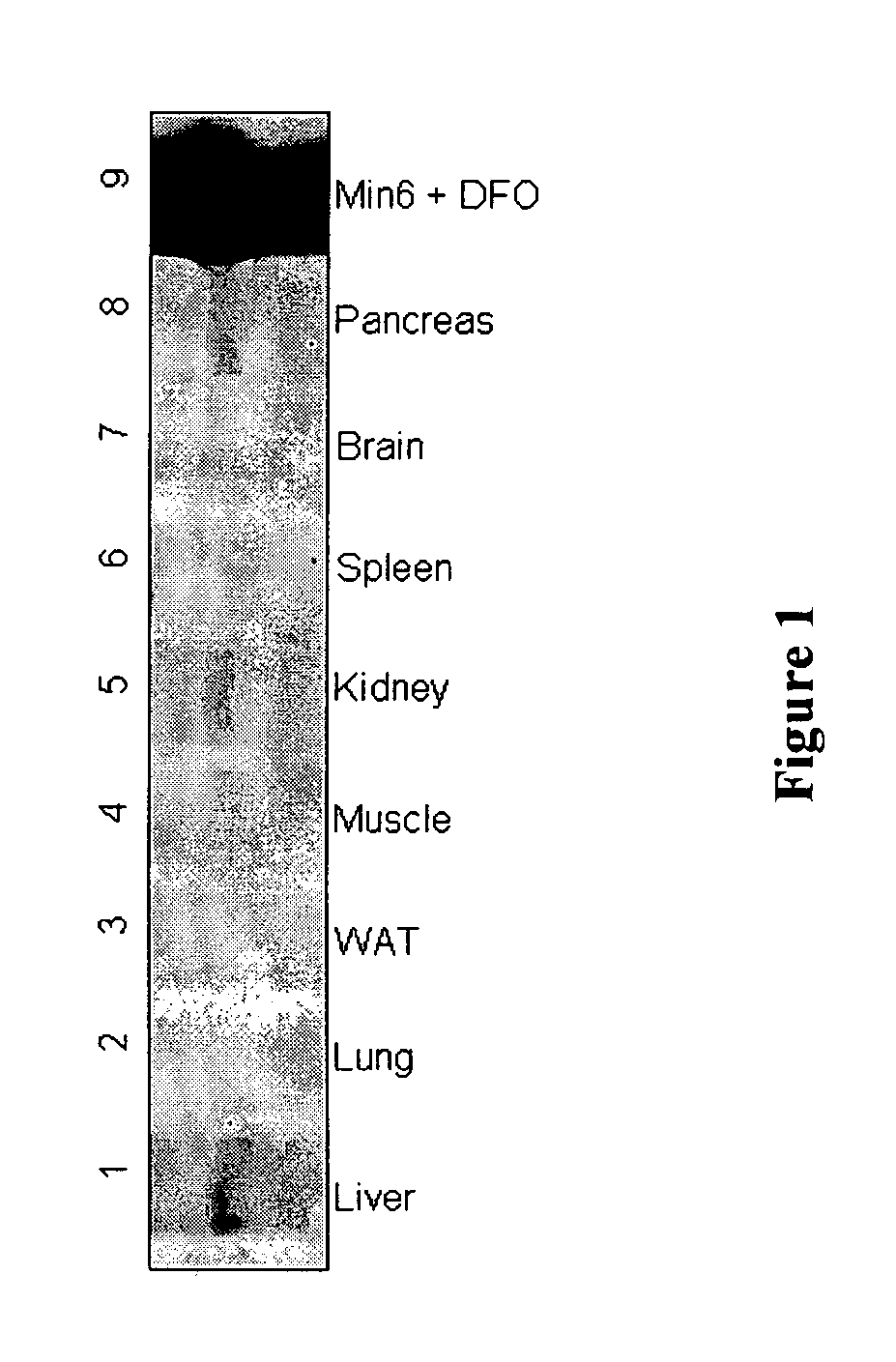

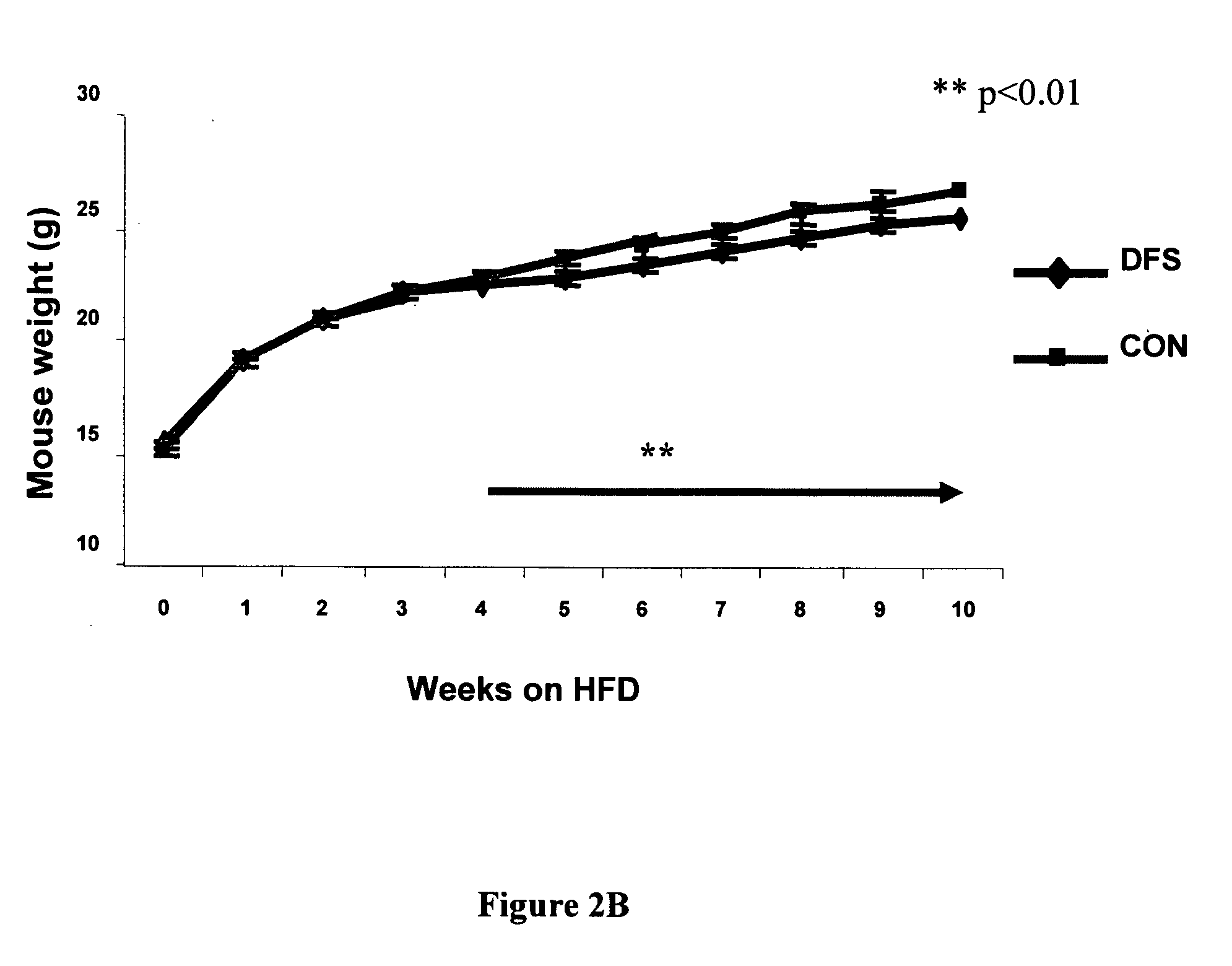

Method of increasing metabolism

InactiveUS20110003013A1Lower levelImprove liver functionHeavy metal active ingredientsBiocideEnergy expenditureObesity

The present invention provides a method for increasing metabolism and / or energy expenditure in a subject, e.g., to treat or prevent obesity and / or a related condition and / or to reduce adiposity, the method comprising increasing the level and / or activity of Hypoxia Induced Factor 1α (HIF-1α) in a cell, tissue or organ of the subject, thereby increasing metabolism in the subject. The present invention also provides a method for increasing metabolism in a subject, the method comprising administering an iron chelating agent to the subject, thereby increasing metabolism in the subject.

Owner:GAVAN INST OF MEDICAL RES ST VINCENTS HOSPITAL

Construction method for preventing efflorescence at corners of building wall

InactiveCN108755980AImprove the effect of later useReduce ubiquitinationBuilding insulationsOXALIC ACID DIHYDRATEEfflorescence

The invention discloses a construction method for preventing efflorescence at corners of a building wall. The construction method comprises the following steps that preparation before construction isconducted; the building wall is constructed, specifically, a foundation and a wall frame of the building wall are constructed; a dry hanging structure is designed, specifically, a red brick layer, a hanging piece, a force-bearing piece and a sound absorption layer are sequentially arranged on the wall frame from outside to inside; the red brick layer is pasted, specifically, before red bricks aremounted, anti-alkali treatment agents are smeared on the back faces and side faces of the red bricks, meanwhile, resin glue is smeared at the bottoms of the red bricks, and then chemical fiber mesh cloths are pasted to form an anti-pull waterproof layer; whitewashing is conducted, specifically, putty whitewashing is conducted on the outer side of the mounted red brick layer; and prevention treatment is conducted, specifically, the whitewashed wall is washed through 10% of an oxalic acid solution and washed through fresh water after being washed completely, and after being fully dried, the wallis sprayed through a solidification waterproof agent. The construction method starts from the three aspects of design preparation before construction, reducing of generation of substances such as Ca(OH) 2 and salt, and prevention treatment after construction, and generation of the efflorescence phenomenon at the corners of the building wall is lowered.

Owner:马新伟

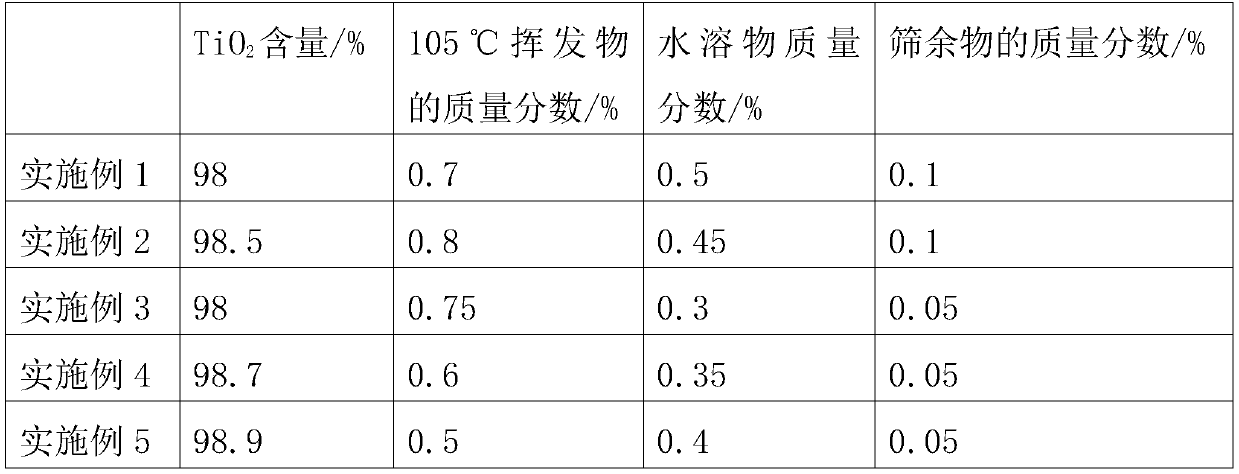

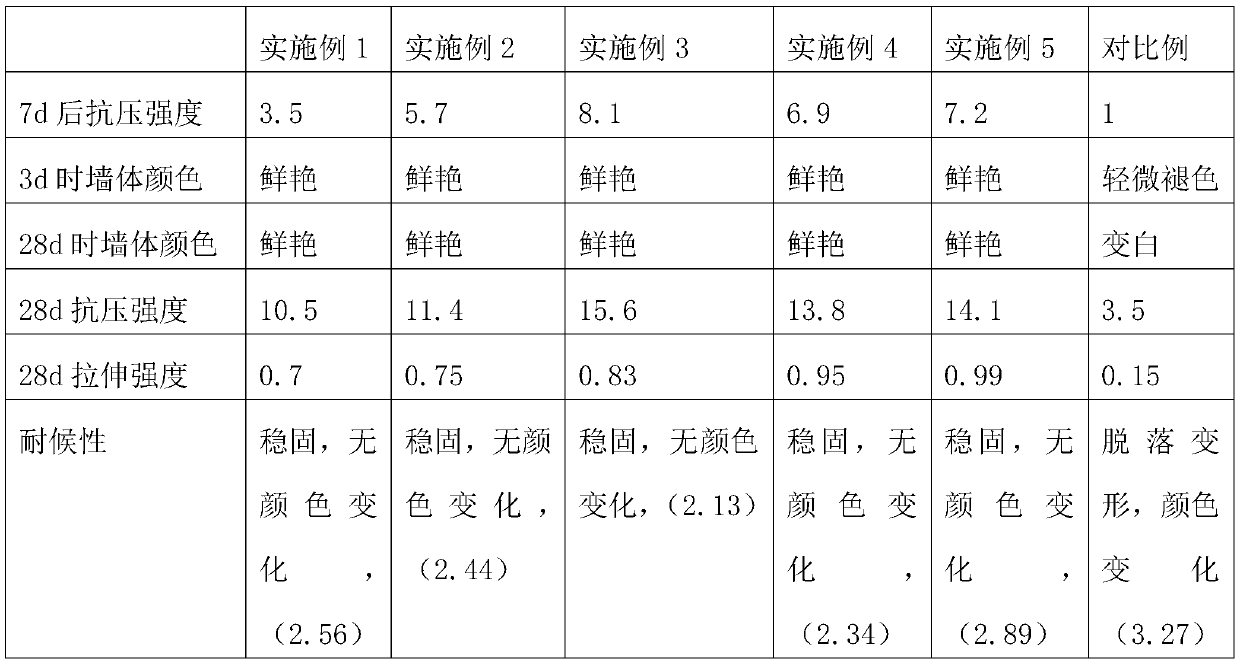

Preparation method of modified titanium dioxide, modified titanium dioxide and application

ActiveCN111533167AGood weather resistanceLow elastic modulusTitanium dioxideUltraviolet lightsNanostructured titanium

The invention provides a preparation method of modified titanium dioxide, the modified titanium dioxide and application, and solves the technical problems that color mortar in the prior art is poor inweather resistance, and efflorescence easily occurs to dry-mixed mortar using Portland cement as a cementing material. The preparation method comprises the following steps: (1) gasifying butyl titanate; (2) adding water into a reactor for reaction to obtain nano TiO2; (3) cooling to 20-25 DEG C; and (4) carrying out screen analysis to obtain the modified titanium dioxide finished product. The modified titanium dioxide prepared by the method can be used as a weather-resistant additive to be added into colored dry-mixed mortar, and the modified nano titanium dioxide absorbs ultraviolet light and reflects a large amount of visible light so that the brilliance of colors can be enhanced; meanwhile, it can be guaranteed that the polymer in the cement paste body and the cement paste body cannotbe separated from each other due to the difference of linear expansion coefficients, and thus attachment of the polymer to Portland cement and refinement and filling of capillary pores are guaranteed.

Owner:鑫统领建材集团有限公司

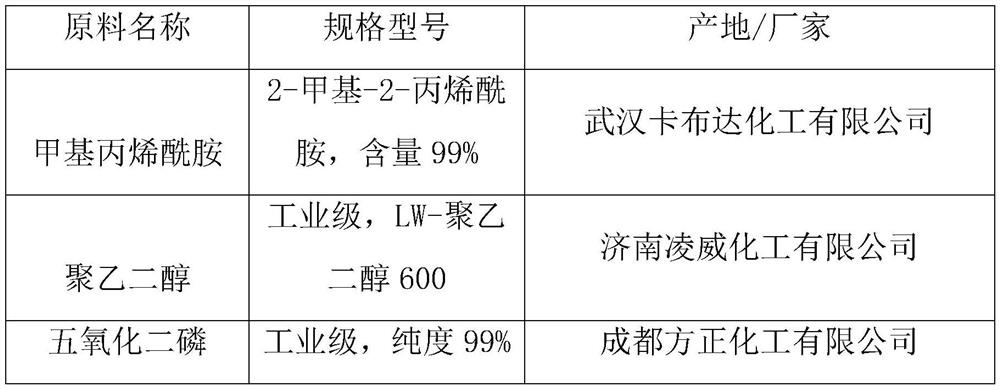

Viscosity reducer for concrete and preparation method thereof

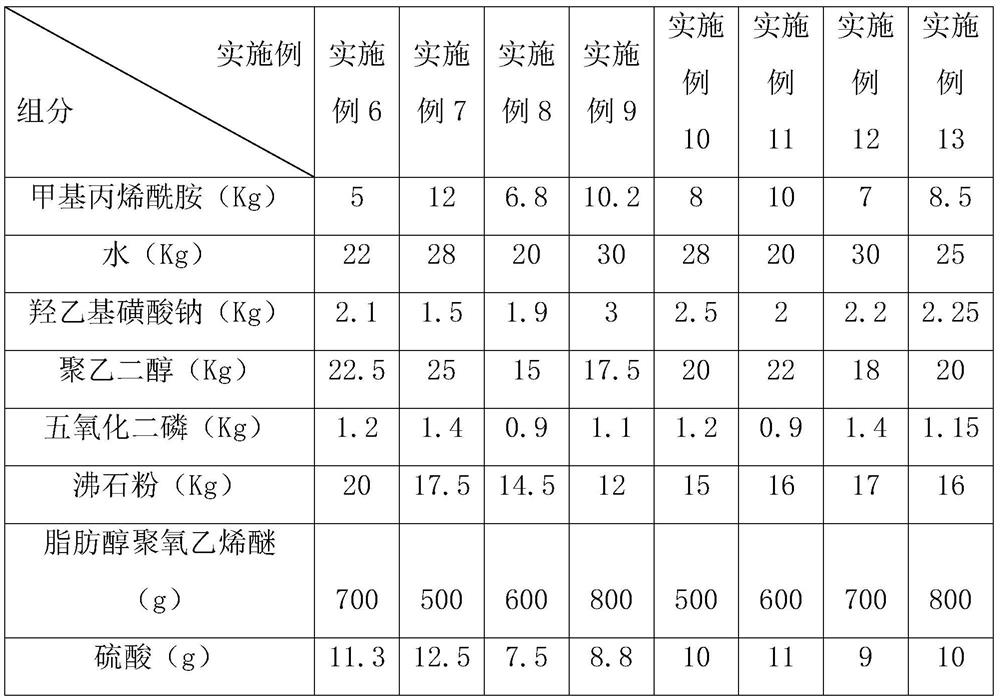

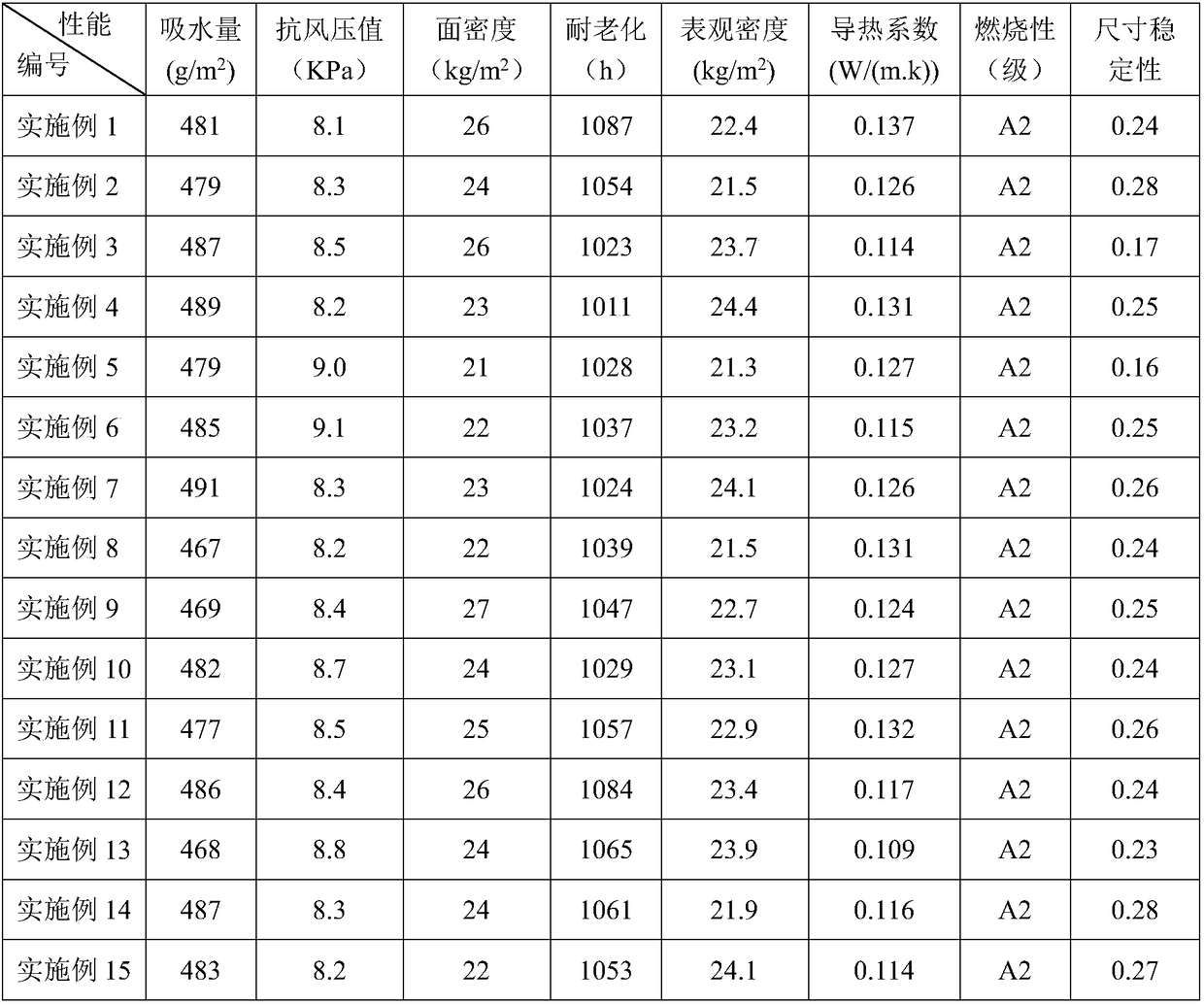

The invention discloses a viscosity reducer for concrete and a preparation method thereof, and relates to the technical field of building materials. A viscosity reducer for concrete, mainly made of the following viscosity reducer raw materials in parts by weight: 5-12 parts of methacrylamide, 20-30 parts of water; the viscosity reducer raw materials also include regulator and polyethylene Glycol phosphate compound; The conditioner comprises the following parts by weight conditioner raw material: 1.5-3 parts of surfactant; the polyethylene glycol phosphate compound is mainly made of raw materials comprising the following parts by weight: polyethylene 15-25 parts of diol, 0.9-1.4 parts of phosphorus pentoxide, 12-20 parts of zeolite powder. It has the advantage of improving the crack resistance of concrete. The preparation method comprises the following steps: modulation, preparation of viscosity reducing agent and the like.

Owner:四川鼎德商品混凝土有限公司

Method for manufacturing exterior wall decorative board

The invention provides a method for manufacturing an exterior wall decorative board. The exterior wall decorative board is formed by laminating a decorative surface layer and a middle material layer.The decorative surface layer is externally sprayed with a decorative surface layer material, and the middle layer material is beater-addition molded by a beater-addition machine. The decorative surface layer material is prepared from the following ingredients (by weight): 100 parts of slag, 0-50 parts of coal gangue, 1-25 parts of an alkaline activator, 20-50 parts of water, 5-28 parts of pulp fiber, 1-30 parts of a pigment and 0.5-1 part of polypropylene fiber. The middle layer material is prepared from the following ingredients (by weight): 100 parts of slag, 0-70 parts of coal gangue, 1-22parts of an alkaline activator, 10-40 parts of water, 5-42 parts of pulp fiber and 0.5-2 parts of polypropylene fiber. By the technical scheme of the invention, potential hydraulicity of slag-coal gangue is fully utilized, a high-strength product which achieves various performance indexes of the exterior wall decorative board is generated at a high hydration speed, the blank quality of the board is guaranteed, and mass production can be realized.

Owner:HEBEI ZHUODA BUILDING MATERIALS RES INST CO LTD

A kind of preparation method of building tile grout

The invention belongs to the technical field of building materials, and discloses a preparation method of a building tile joint filler. The preparation method of the building tile joint filler of the present invention comprises: (1) dissolving polyvinyl alcohol in ethanol aqueous solution, and then adding water-soluble resin liquid to obtain polyvinyl alcohol glue; (2) pulverizing natural zeolite, heat preservation and heat treatment to obtain Pretreatment zeolite; (3) Add alkali solution to ethanol aqueous solution of ethyl orthosilicate, control pH to 8‑10, then add lithium nitrate, stir and react, and mix the obtained solution with pretreatment zeolite to obtain modified zeolite; (4 ) Mix graphite with oxidant and stir to react to obtain graphite oxide; (5) Take cement, quartz sand, pigment, polyvinyl alcohol glue, modified zeolite and graphite oxide, stir and mix, then add water, and stir to obtain tile joint sealant . The method is suitable for large-scale industrial application, the process is simple, the cost is low, and it is easy to popularize, and the prepared ceramic tile grout has excellent mechanical properties and good pan-alkali resistance.

Owner:广东靓砂建材科技有限公司

Adhering construction process for natural stone for garden pond

InactiveCN102677880AImprove the decorative effectReduce ubiquitinationBuilding constructionsAlkalinityAdhesive cement

The invention belongs to the technical field of building materials, and in particular relates to an adhering construction process for a natural stone for a garden pond, comprising the following steps of: firstly, adding dry powder mortar into water, and stirring uniformly to obtain mortar; secondly, scrapping the mortar on a concrete surface or brick wall surface, screeding, compacting and drying to obtain a mortar layer; thirdly, painting waterproof paint on the surface of the mortar layer, and then drying to obtain a waterproof paint layer; fourthly, adding a stone adhesive into water, and stirring uniformly to obtain a stone adhesive cement; fifthly, scrapping the stone adhesive cement on the surface of the waterproof paint layer to obtain a stone adhesive layer; and sixthly, pressing the natural stone on the stone adhesive layer. Compared with the prior art, the adhering construction process has the advantages that alkaline matters in the concrete surface or brick wall surface and the mortar layer are isolated from arriving at the surface through the waterproof paint layer, the stone adhesive layer is made of cement with low alkalinity, and therefore, the possibility of causing a saltpetering phenomena is reduced, and then, the saltpetering phenomena are reduced.

Owner:张立功

Novel single-layer material for building outer wall or ground and construction process

InactiveCN113060980AGood adhesionImprove water resistanceCovering/liningsCelluloseHydroxyethyl cellulose

The invention discloses a novel single-layer material for a building outer wall or ground and a construction process of the novel single-layer material. The novel single-layer material comprises 20-50 parts of cement, 1-5 parts of methyl cellulose or hydroxypropyl methyl cellulose or hydroxyethyl cellulose or carboxymethyl cellulose, 10-20 parts of calcium carbonate or heavy calcium carbonate or calcium superphosphate, 1-5 parts of latex powder, 0.3-0.6 part of wood fiber and 0.1-0.5 part of polypropylene fiber. The construction process comprises the following steps of: (1) mounting a plurality of metal groove strips on an outer wall of a building or the ground in the up-down and left-right directions; (2) leveling a surface layer; (3) conducting watering and maintaining; (4) fixedly mounting a plurality of metal buckle plates among the plurality of crisscrossed metal groove strips through buckles and stickers; and (5) conducting gap beautifying on the wall. The novel single-layer material has the advantages of excellent water resistance, lasting water resistance, high stain resistance, air permeability, high weather resistance, ultra-long service life, better color retention, lasting and beautiful characteristics, diversity such as adjustable colors and selectable textures, and constructability such as convenient operation and good constructability.

Owner:江豪

Method for reducing radioactivity of red mud

InactiveCN101219849BLow radioactivityRadiation blockingSludge treatmentSolid waste managementRed mudNational standard

The invention discloses a method for reducing radioactivity of red mud, in which barium sulfate powder is added into the red mud and then mixed together; after being milled by a ball miller, the limeis added into the mixture, then mixed and milled again to obtain construction material which can be directly used. The invention has the advantages that: the barium sulfate powder is added into the red mud to effectively reduce the radioactivity of the red mud; when the red mud is determined to use as the construction material, the radioactivity can not exceed the national standard. The barium sulfate powder and the red mud are mixed to immediately reduce the radioactivity of the red mud by 10-20 percent; through precipitating for 8-12 hours, the radioactivity of the red mud is further reducedby around 20 percent; the construction material of the red mud prepared at last is detected and the radioactivity is between 0.4-0.8 percent which is below the national standard. Compared with priorart, the invention has the advantages of effectively reduce the radioactivity of the red mud , simple preparation process, low production cost and so on.

Owner:贵阳超群实业有限公司

A kind of water base anti-alkali permeable floor coating and preparation method thereof

ActiveCN109749604BHigh hardnessImprove wear resistanceAntifouling/underwater paintsPaints with biocidesAntifungalEmulsion

Owner:NANJING CHANGJIANG PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com