Viscosity reducer for concrete and preparation method thereof

A viscosity reducer and concrete technology, which is applied in the field of building materials, can solve the problems of high-strength concrete crack resistance and poor compatibility, and achieve the effects of reducing efflorescence, reducing cracks, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

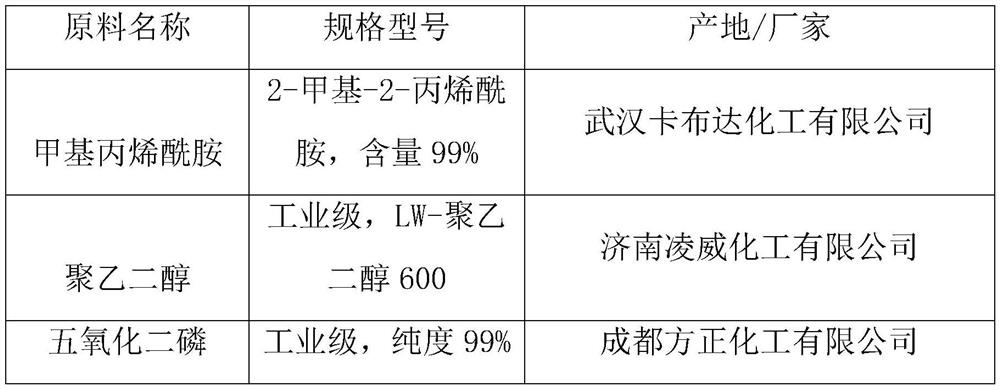

Method used

Image

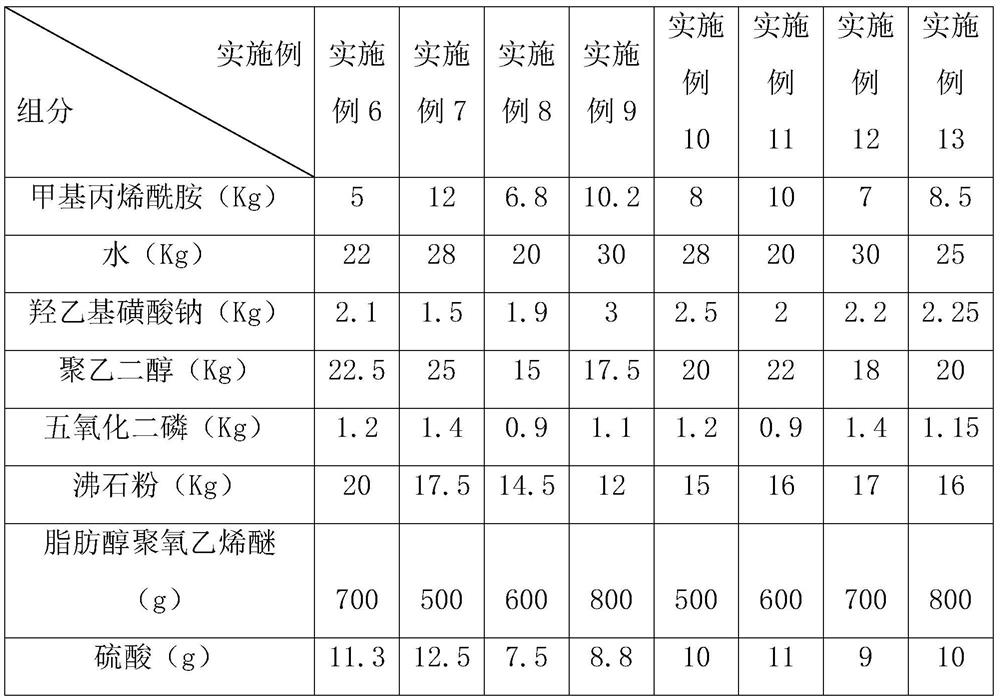

Examples

Embodiment 1

[0038] Embodiment 1: a kind of preparation method of concrete viscosity reducer, comprises the steps:

[0039] S1 preparation: Weigh 25kg of water, add 2.25kg of sodium isethionate and 600g of fatty alcohol polyoxyethylene ether, and then add 8.5kg of methacrylamide, and mix evenly to prepare a precursor solution.

[0040] S2 Viscosity reducer preparation: sieve the zeolite powder with a sieve with a pore size of 45 μm, select the zeolite powder with a particle size not greater than 45 μm, and dry the zeolite powder with a particle size not greater than 45 μm at 150° C. for 120 minutes to obtain a dry zeolite powder. Standby; take 20kg of polyethylene glycol, stir at 25°C at a speed of 200 rpm, add 1.15kg of phosphorus pentoxide dropwise, the system releases heat during the dropwise addition of phosphorus pentoxide, cool down with a water bath, and control the feeding speed to make The temperature is not higher than 28°C. After the feeding is completed, continue to stir for 30...

Embodiment 2

[0042] The difference between embodiment 2 and embodiment 1 is that no fatty alcohol polyoxyethylene ether is added in embodiment 2, and the others are consistent with embodiment 1.

Embodiment 3

[0044] The difference between embodiment 3 and embodiment 1 is that embodiment 3 replaces sodium isethionate with sodium dodecyl sulfonate of equal quality (provided by Jinan Xinwang Chemical Co., Ltd., superior product), and others are all the same as those in the implementation Example 1 remains the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com