A kind of water base anti-alkali permeable floor coating and preparation method thereof

A permeable floor and water-based technology, applied in the field of coatings, to achieve the effects of tough paint film, excellent alkali resistance and weather resistance, environmental friendliness and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Examples 1-4 prepared water-based alkali-resistant and permeable floor coatings, and Comparative Example 1 was a commercially available solvent-based permeable floor coating. In Comparative Example 2, the ratio of thickener ACRYSOL RM-2020 to TAFIGEL PUR40 is 1:2, and the others are the same as in Example 1. In comparative example 3, no inorganic anti-alkali auxiliary agent was added, and the others were the same as in Example 1.

[0052] Example 1

[0053] This embodiment provides a water-based anti-alkali and permeable floor coating, including two components A and B, wherein component A contains the following components accounting for the mass percentage of component A:

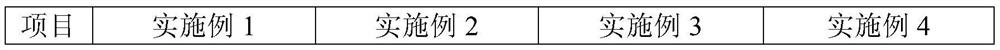

[0054] Components and dosages of component A in Table 1 Examples 1 to 4

[0055]

[0056]

[0057] Table 1-2 Composition and dosage of component A in comparative examples 1 to 3

[0058]

[0059]

[0060] Table 1-3 Components and dosages of component B in Examples 1 to 4 and Comparativ...

Embodiment 1~4 and comparative example 2~3

[0063] The preparation method of embodiment 1~4 and comparative example 2~3

[0064] The preparation of component A includes the following steps: first add 60% deionized water in component A to the paint mixing pot, add half of the dispersant and bactericide at a speed of 900r / min, disperse for 7 minutes, and Add the pigment at the speed of 2000r / min and disperse for 0.5 hours at the speed of 2000r / min, then add half of the defoamer and continue to disperse at the speed of 1500r / min for 5min and then stand for 0.5h, then grind it in a sand mill to fineness ≤20μm, get the resin-free water-based color paste, save it for later use;

[0065] Then add resin-free water-based color paste, hydroxyacrylic acid emulsion and 40% deionized water in Part A to the paint mixing pot, stir for 10 minutes at a speed of 1000r / min, and then add wetting agent at a speed of 800r / min , the remaining bactericide, the remaining defoamer, and inorganic anti-alkali additives, the test pH value is betwe...

Embodiment 1-4 and comparative example 2-3

[0070] The preparation method of embodiment 1-4 and comparative example 2-3

[0071] The preparation of component B includes the following steps:

[0072] In the mixing container, first add alcohol ether solvent; after mixing and stirring at a speed of 1000r / min for 0.5h, add a dehydrating agent, stir evenly and let stand for 30min;

[0073] Add water-based aliphatic isocyanate curing agent, mix and stir evenly at a speed of 600r / min, test the viscosity and non-volatile content, filter with 120-mesh silk cloth, and then obtain component B, and save it for later use.

[0074] The components A and B are mixed according to the weight ratio of 8:1, and after stirring evenly, the water-based alkali-resistant and permeable floor coating (Example 1) is obtained.

[0075] The components A and B are mixed according to the weight ratio of 5:1, and the water-based alkali-resistant and permeable floor coating (Example 2) is obtained after stirring evenly.

[0076] The components A and B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com