Preparation method of modified titanium dioxide, modified titanium dioxide and application

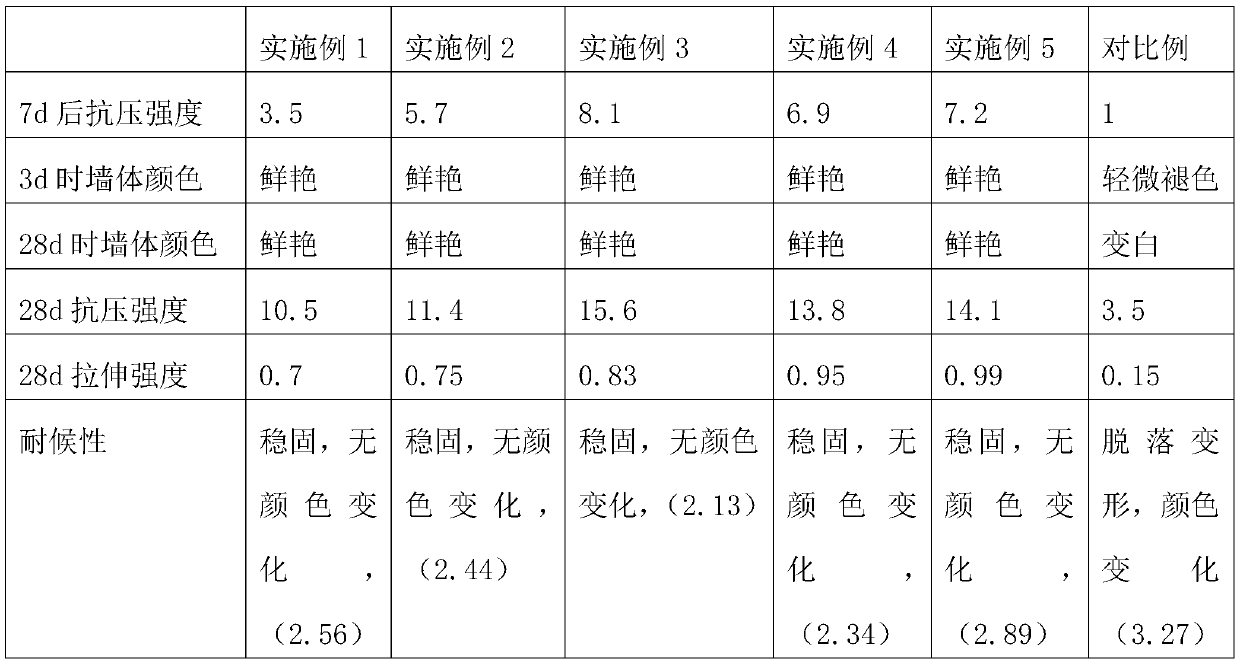

A titanium dioxide and modification technology, which is applied in the field of titanium dioxide, can solve the problems of efflorescence and poor weather resistance of colored mortars, and achieve the effects of enhancing vividness, reducing efflorescence, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

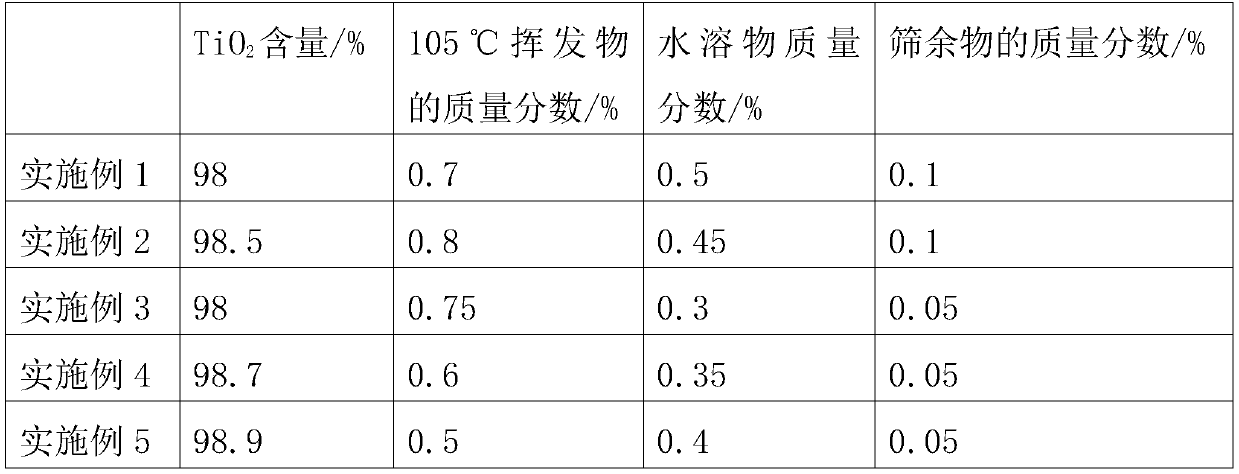

Examples

Embodiment 1

[0050] Preparation of modified titanium dioxide:

[0051] Raw materials (by weight): 1 part of butyl titanate, 10 parts of water;

[0052] A1. Add butyl titanate to the reactor, at a temperature of 85°C, N 2 Vaporize butyl titanate under protection;

[0053] A2. Add water into the reactor; when the reaction temperature is 525°C and the pressure is 1.01×10 5 Pa, N 2 Reaction under the protection of (nitrogen flow rate 1L / min, water vapor flow rate 1L / min, reaction time 30min), to obtain R818 nano-TiO 2 ;

[0054] A3, the nano-TiO that step A2 obtains 2 placed under inert gas CO 2 cool down to 23°C in an atmosphere;

[0055] A4, the TiO obtained by cooling in step A3 2 Placed in a 45μm round hole sieve to control TiO 2 The content is more than 98%, the sieve residue is less than 0.01%, the volatile matter at 105°C is less than 0.05%, and the L value ranges from 98.5 to 100, and the finished product of modified titanium dioxide is obtained.

Embodiment 2

[0057] Preparation of modified titanium dioxide:

[0058] Raw materials (by weight): 1 part of butyl titanate, 15 parts of water;

[0059] A1. Add butyl titanate to the reactor, at a temperature of 60°C, N 2 Vaporize butyl titanate under protection;

[0060] A2. Add water to the reactor; when the reaction temperature is 510°C and the pressure is 1.5×10 5 Pa, N 2 Reaction under the protection of (nitrogen flow rate 1L / min, water vapor flow rate 1L / min, reaction time 30min), to obtain R818 nano-TiO 2 ;

[0061] A3, the nano-TiO that step A2 obtains 2 placed under inert gas CO 2 Cool down to 22°C in an atmosphere;

[0062] A4, the TiO obtained by cooling in step A3 2 Placed in a 45μm round hole sieve to control TiO 2 The content is more than 98%, the sieve residue is less than 0.01%, the volatile matter at 105°C is less than 0.05%, and the L value ranges from 98.5 to 100, and the finished product of modified titanium dioxide is obtained.

Embodiment 3

[0064] Preparation of modified titanium dioxide:

[0065] Raw materials (by weight): 1 part of butyl titanate, 6 parts of water;

[0066] A1. Add butyl titanate into the reactor, at a temperature of 110°C, N 2 Vaporize butyl titanate under protection;

[0067] A2. Add water into the reactor; when the reaction temperature is 530°C and the pressure is 0.5×10 5 Pa, N 2 Reaction under the protection of (nitrogen flow rate 1L / min, water vapor flow rate 1L / min, reaction time 20min) to obtain R818 nano-TiO 2 ;

[0068] A3, the nano-TiO that step A2 obtains 2 placed under inert gas CO 2 cool down to 24°C in an atmosphere;

[0069] A4, the TiO obtained by cooling in step A3 2 Placed in a 45μm round hole sieve to control TiO 2 The content is more than 98%, the sieve residue is less than 0.01%, the volatile matter at 105°C is less than 0.05%, and the L value ranges from 98.5 to 100, and the finished product of modified titanium dioxide is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com