A coloring agent suitable for 3D printing white cement-based materials and its use and application

A 3D printing and white cement technology, which is applied in the field of building materials, can solve the problems of easy efflorescence on the surface of products, poor dispersion of colorants, collapse, etc., and achieve the effects of reducing efflorescence, reducing cement alkalinity, and increasing plastic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

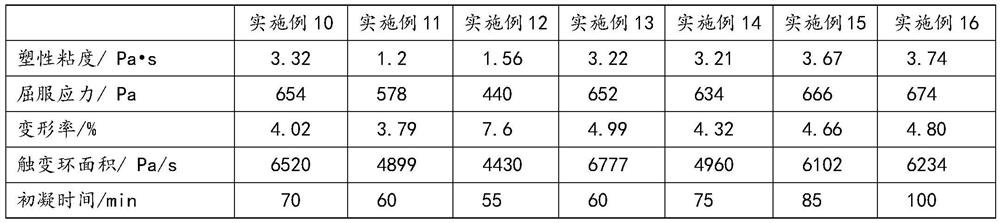

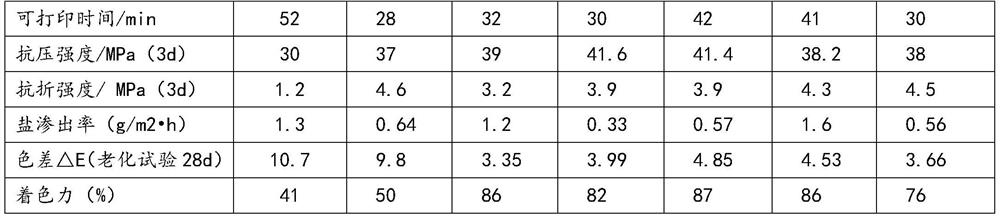

Examples

Embodiment 1

[0037]A colorant suitable for 3D printing white cement-based materials, in parts by weight, the colorant comprises the following components: 2 parts of silane coupling agent, 5 parts of polymer emulsion, 30 parts of phenolic resin, and mineral admixture 20 parts, 17 parts of pigments, 28 parts of coagulant, 9 parts of water reducing agent, 1.1 parts of defoamer, and 110 parts of water. The polymer emulsion is polyacrylate emulsion; the mineral admixture is microsilica fume (whiteness is 89); the pigment is azo red; the coagulant is calcium nitrate; the water reducing agent It is a non-air-entraining polycarboxylate water reducer.

Embodiment 2

[0039] A colorant suitable for 3D printing white cement-based materials, in parts by weight, the colorant includes the following components: 5 parts of silane coupling agent, 16 parts of polymer emulsion, 17 parts of phenolic resin, and mineral admixture 10 parts, 20 parts of pigment, 9 parts of coagulant, 7 parts of water reducer, 0.05 part of defoamer, and 120 parts of water. The polymer emulsion is styrene-acrylic emulsion; the mineral admixture is lithium slag (whiteness is 90); the pigment is chrome green; the coagulant is potassium sulfate; Gas type polycarboxylate water reducer.

Embodiment 3

[0041] A colorant suitable for 3D printing white cement-based materials, in parts by weight, the colorant includes the following components: 1 part of silane coupling agent, 18 parts of polymer emulsion, 23 parts of phenolic resin, and mineral admixture 30 parts, 5 parts pigment, 30 parts coagulant, 6 parts water reducing agent, 0.15 part defoamer, 105 parts water. The polymer emulsion is vinyl acetate-acrylate copolymer emulsion; the mineral admixture is microsilica powder (whiteness is 91); the pigment is iron oxide blue; the coagulant is calcium sulfate; The water-reducing agent is a low-air-entraining polycarboxylate water-reducing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com