Lithium slag modified ultra-high performance concrete product and preparation method thereof

A concrete product, ultra-high-performance technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of reducing the mechanical properties of concrete, not having potential hydraulicity, reducing the fluidity of concrete, etc., to achieve Reduce the risk of shrinkage cracking and deformation, increase the difficulty of construction, and reduce the effect of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

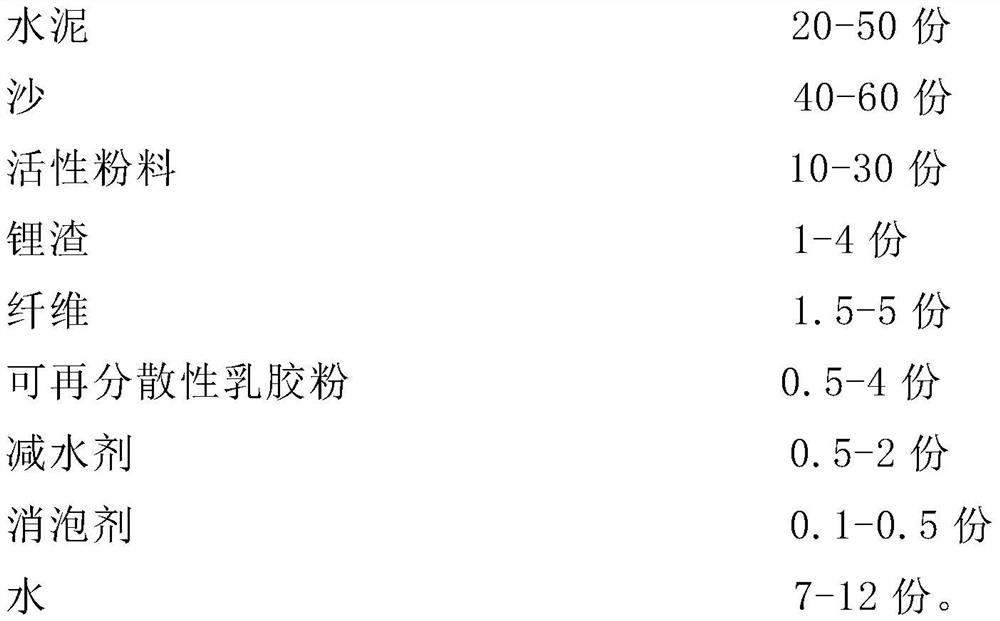

[0021] Embodiment one: take by mass parts:

[0022]

[0023] Its concrete preparation steps are as follows:

[0024] ①Put the redispersible latex powder into the mixer, gradually add lithium slag, stir evenly, add active powder and stir evenly;

[0025] ② Add water reducer and defoamer to water and stir to obtain a mixed solution, add 80% of the mixed solution to the dry powder stirred in the first step and stir for 10-25 minutes, add the remaining mixed solution, and stir for 3-5 minutes;

[0026] ③Slowly add fiber and stir evenly;

[0027] ④ Mix the stirred slurry with cement and sand in pouring or jetting molds, and demould after 24 hours to obtain ultra-high toughness self-curing cement-based products.

Embodiment 2

[0028] Embodiment two: take by mass parts:

[0029]

[0030]

[0031] Its concrete preparation steps are as follows:

[0032] ①Put the redispersible latex powder into the mixer, gradually add lithium slag, stir evenly, add active powder and stir evenly;

[0033] ② Add water reducer and defoamer to water and stir to obtain a mixed solution, add 80% of the mixed solution to the dry powder stirred in the first step and stir for 10-25 minutes, add the remaining mixed solution, and stir for 3-5 minutes;

[0034] ③Slowly add fiber and stir evenly;

[0035] ④ Mix the stirred slurry with cement and sand in pouring or jetting molds, and demould after 24 hours to obtain ultra-high toughness self-curing cement-based products.

[0036] The invention uses dispersible latex powder to pretreat lithium slag, utilizes the hydrophobicity of organic groups to reduce the water absorption of lithium slag during concrete mixing, and then the dispersible latex powder is redispersed when it m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com