Magnesium smelting reduction deslagging and residual heat recycling device and process

A waste heat recovery device and magnesium smelting technology, applied in the field of metal magnesium smelting, can solve the problems of environmental pollution, dust environmental pollution, and can only be used for underground burial.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

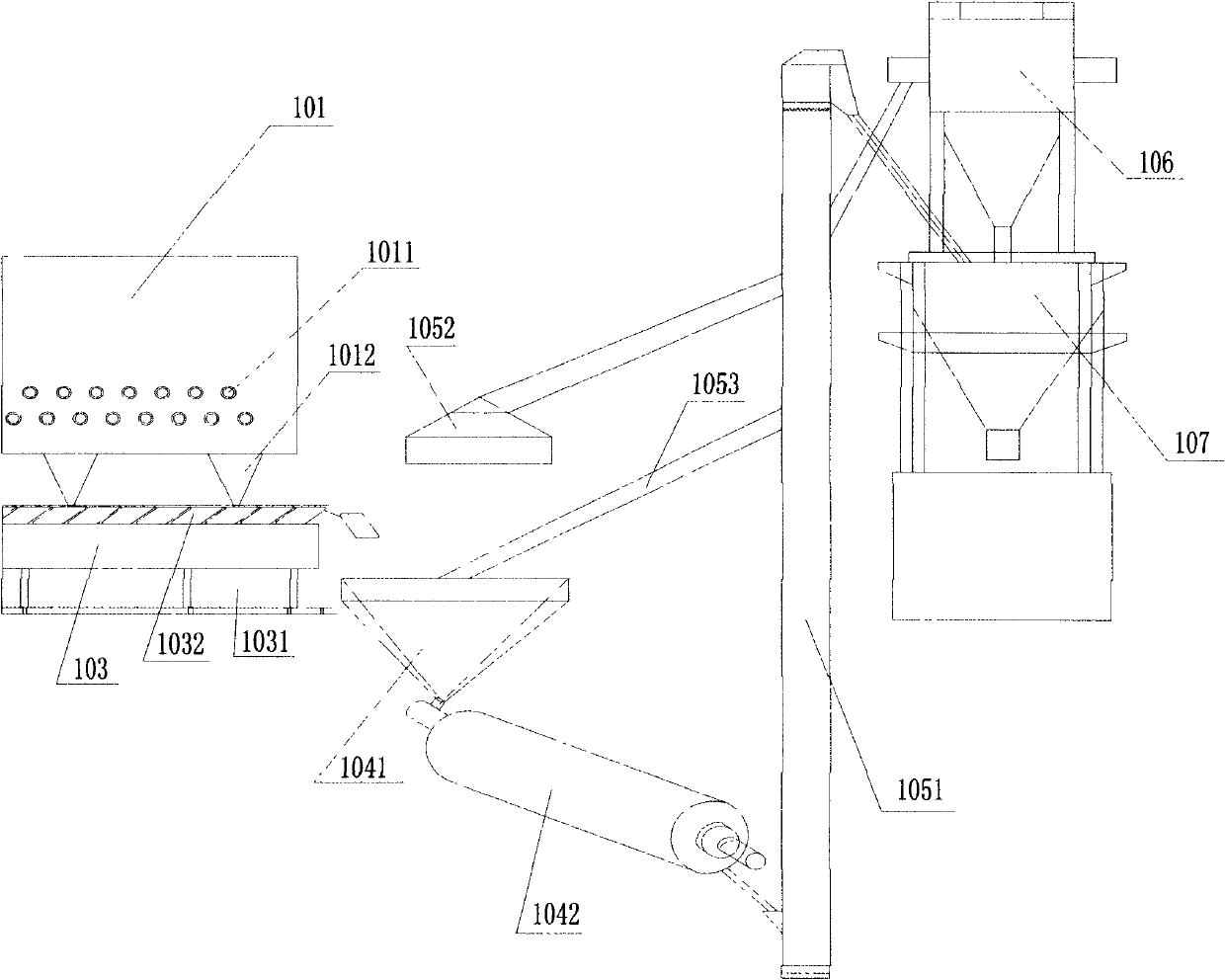

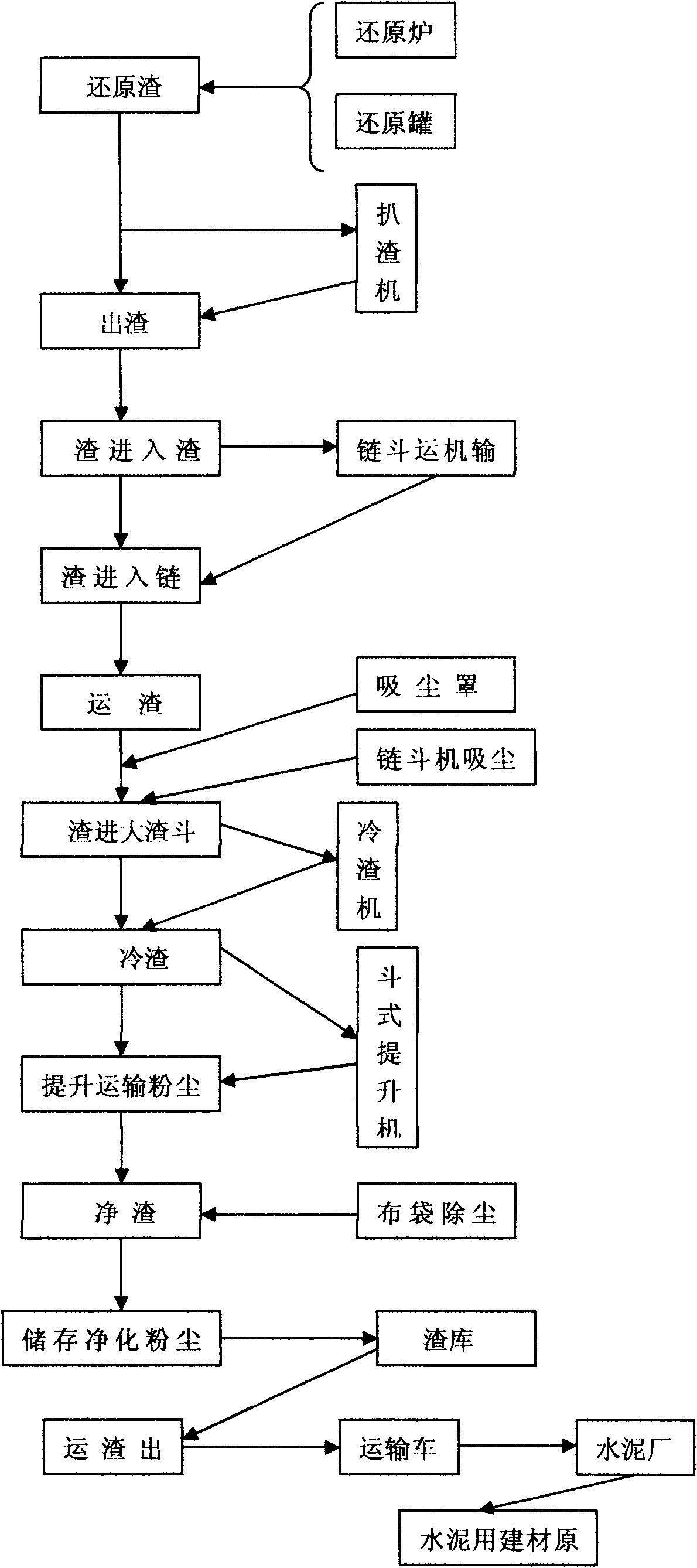

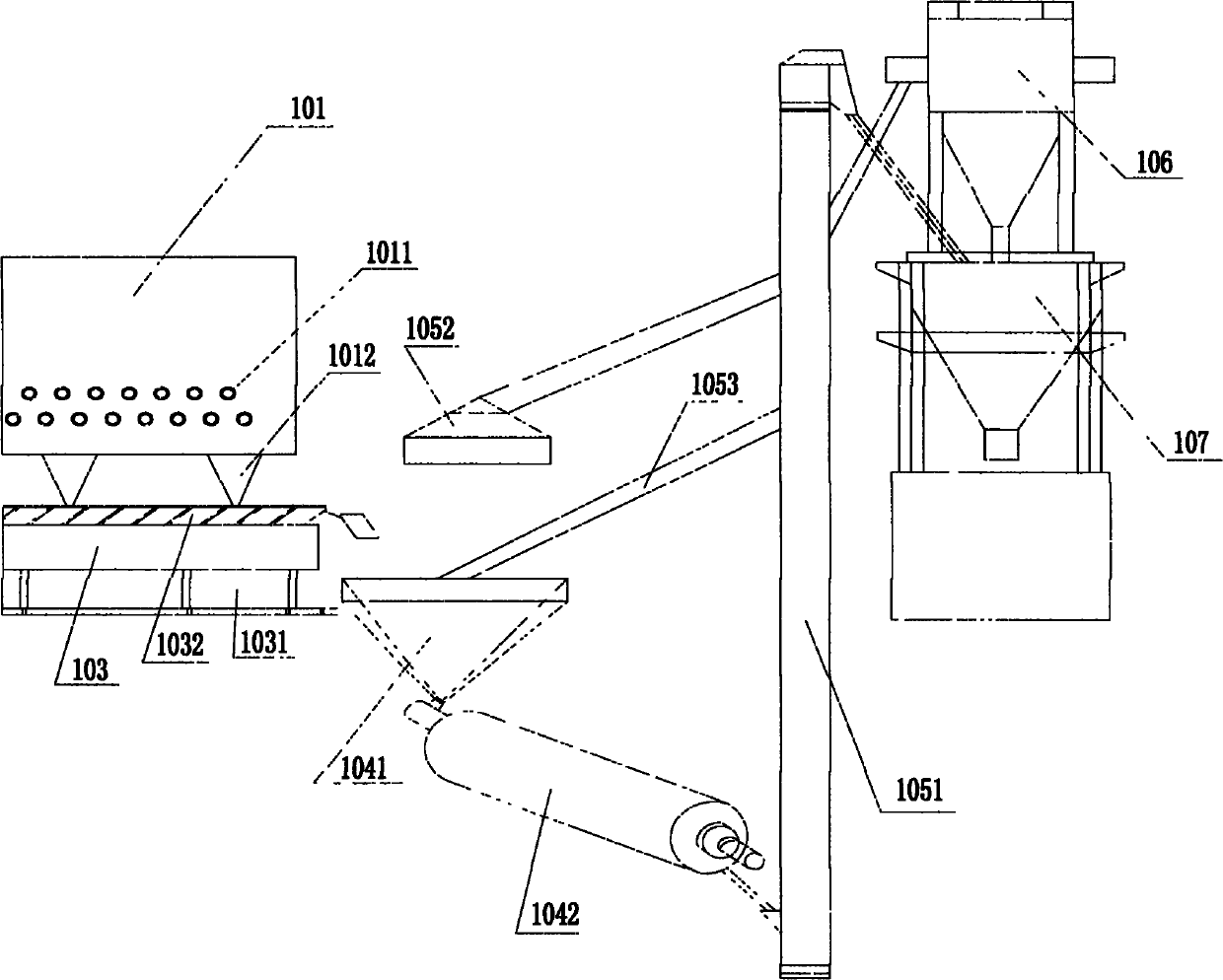

[0024] It is composed of reduction furnace 101, slag removal machine 102, chain bucket conveyor 103, slag cooler 104, bucket elevator 105, bag filter 106 and slag storage 107; reduction furnace 101 is composed of reduction tank 1011 and slag hopper 1012, The reduction tank 1011 is installed in the reduction furnace 101 to carry out the magnesium slag reduction reaction; the slag receiving hopper 1012 under the reduction furnace 101 is used to accept the slag from the reduction reaction; the slag removal machine 102 is installed in front of the reduction furnace 101, The slag scraper 102 has a spiral scraper, which is used to scrape out the slag in the reduction tank 1011; the front of the reduction furnace 101 is equipped with a continuously running chain bucket conveyor 103, and multiple chain bucket conveyors 103 are installed on the chain bucket conveyor 103. Chain hopper 1031, chain hopper 1031 is used to store the slag discharged from slag hopper 1011; slag cooler 104 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com