Solanaceous vegetable culture medium and preparation method thereof

A technology of cultivation substrate and solanaceous fruits, which is applied in plant cultivation and agricultural fields to achieve the effect of rich nutrition and good cultivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

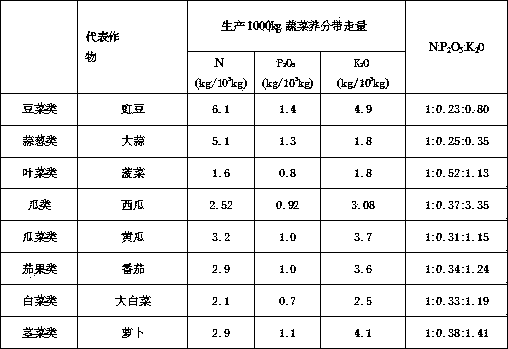

[0030] (1) Adjust the carbon-nitrogen ratio and water content of the waste bedding of the fermentation bed cleaned out of the pigsty. The carbon-nitrogen ratio is controlled at (16~25):1, and the water content is controlled at 50%~60%;

[0031] Water content control method: The general water content of the waste bedding in the fermentation bed is 30-40%, and the water content can reach 50% to 60% by adding water;

[0032] Carbon-nitrogen ratio control method: If the carbon-nitrogen ratio of the waste bedding of the fermentation bed is removed from the pig sty, adjust it by adding pig manure (the carbon-nitrogen ratio of pig manure is about 12:1), and if it is low, adjust it by adding straw (straw carbon-nitrogen ratio). ratio is around 50:1).

[0033] (2) Stack the treated waste bedding material for fermentation, turn it over every two days, and stack and ferment to 80%±2% of decomposed maturity; generally, it takes 1 to 2 months to ferment; The whole fermentation process sho...

Embodiment 2

[0038] (1) Adjust the carbon-nitrogen ratio and water content of the waste bedding of the fermentation bed cleaned out of the pigsty. The carbon-nitrogen ratio is controlled at (16~25):1, and the water content is controlled at 50%~60%;

[0039] Water content control method: The general water content of the waste bedding in the fermentation bed is 30-40%, and the water content can reach 50% to 60% by adding water;

[0040] Carbon-nitrogen ratio control method: If the carbon-nitrogen ratio of the waste bedding of the fermentation bed is removed from the pig sty, adjust it by adding pig manure (the carbon-nitrogen ratio of pig manure is about 12:1), and if it is low, adjust it by adding straw (straw carbon-nitrogen ratio). ratio is around 50:1).

[0041] (2) Stack the treated waste bedding material for fermentation, turn it over every two days, and stack and ferment to 80%±2% of decomposed maturity; generally, it takes 1 to 2 months to ferment; The whole fermentation process sho...

Embodiment 3

[0045] (1) Adjust the carbon-nitrogen ratio and water content of the waste bedding of the fermentation bed cleaned out of the pigsty. The carbon-nitrogen ratio is controlled at (16~25):1, and the water content is controlled at 50%~60%;

[0046] Water content control method: The general water content of the waste bedding in the fermentation bed is 30-40%, and the water content can reach 50% to 60% by adding water;

[0047] Carbon-nitrogen ratio control method: If the carbon-nitrogen ratio of the waste litter from the fermentation bed is removed from the sty, adjust by adding pig manure (the carbon-nitrogen ratio of pig manure is about 12:1), if it is low, adjust by adding straw (straw carbon-nitrogen ratio). ratio is around 50:1).

[0048] (2) Stack the treated waste bedding material for fermentation, turn it over and throw it every two days, and stack and ferment to 80% ± 2% of the maturity; generally, it takes 1 to 2 months to ferment; The whole fermentation process should b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com