Molten metal magnesium solution or molten magnesium alloy solution filtering material and filter

A filter material, magnesium alloy technology, applied in the direction of filtration separation, metal processing equipment, chemical instruments and methods, etc., can solve the problems of excessive content of inclusions and flux, reduce the mechanical properties and corrosion resistance of magnesium alloys, and achieve low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

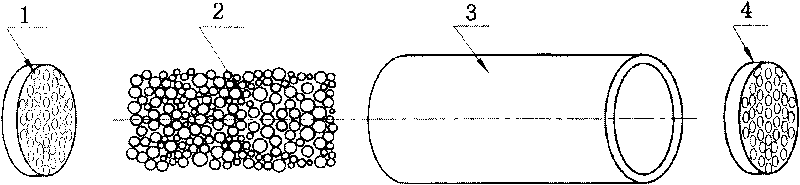

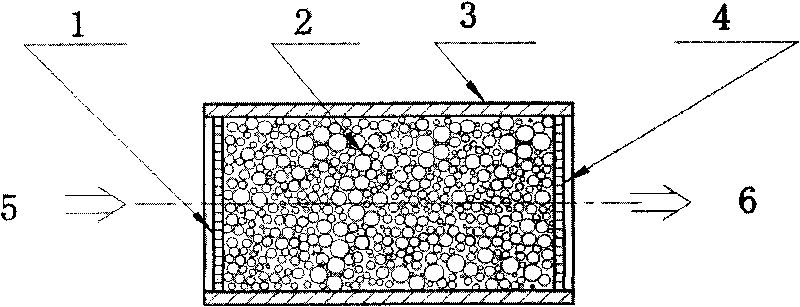

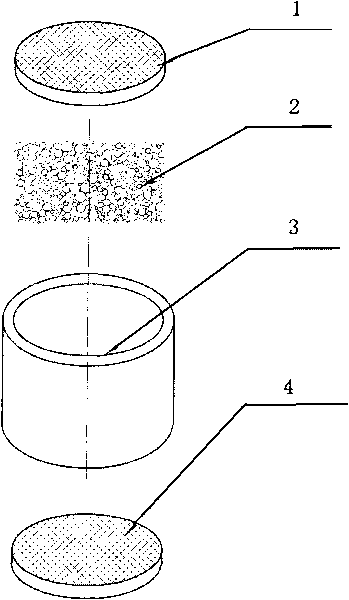

[0024] Such as Figure 1 to Figure 4 As shown, the structure of the pipeline filter and the structure of the screen filter are the same, and the difference is that the diameter and length of the screen filter are respectively greater than the diameter and length of the pipeline filter; another difference Yes, the pipeline filter is mainly used in the pipeline of metal magnesium melt or magnesium alloy melt, while the screen filter is mainly used in the inlet or casting outlet of the delivery pump or casting outlet of metal magnesium melt or magnesium alloy melt.

[0025] Such as Figure 1 to Figure 4 As shown, the filter of the present invention is mainly made of magnesia ceramic particles and / or calcium oxide ceramic particles 2, a container 3 made of high chromium steel or low carbon steel, and 2 high chromium steel or low carbon steel Baffle plate 1,4 constitutes. Ceramic particles 2 of various sizes (1 mm to 50 mm in size) are uniformly filled in a container 3 made of hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com