Comprehensive treatment method for glyphosate mother liquid

A technology of glyphosate mother liquor and treatment method, which is applied in the field of comprehensive treatment of waste mother liquor, can solve the problems of not mentioning the treatment method and fundamentally solving the problem of the outlet of glyphosate mother liquor, achieving good economic benefits and reducing environmental protection The effect of pressure and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

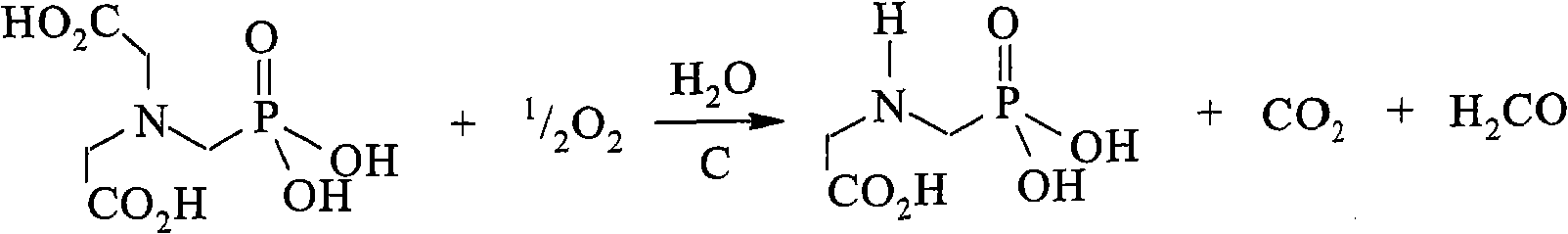

Method used

Image

Examples

Embodiment 1

[0034] After the 300Kg glyphosate mother liquor (glyphosate=1.0wt%, formaldehyde=3.7wt%) is pretreated and filtered, enter the three-stage membrane concentration system for concentration: after the glyphosate dilute mother liquor passes through the first-stage membrane, it is divided into Concentrated liquid and light liquid are divided into two parts, among which concentrated liquid 1 (glyphosate=4.7wt%, formaldehyde=2.0wt%); concentrated liquid 1 continues to enter the secondary membrane to concentrate, and dilute liquid 1 is collected; concentrated liquid 1 passes through the secondary After the membrane is concentrated, it is divided into two parts, the strong liquid 2 and the weak liquid 2. In the strong liquid 2 (glyphosate=6.2wt%, formaldehyde=3.2wt%), the light liquid 2 is collected; the strong liquid 2 continues to enter the three-stage membrane concentration; It is further divided into two parts, the strong liquid 3 and the weak liquid 3, wherein in the strong liquid ...

Embodiment 2

[0037] After the 100Kg glyphosate mother liquor (glyphosate=1.0wt%, formaldehyde=3.7wt%) is pretreated and filtered, enter the three-stage membrane concentration system for concentration: after the glyphosate dilute mother liquor passes through the first-stage membrane, it is divided into Concentrated liquid and light liquid are divided into two parts, among which concentrated liquid 1 (glyphosate=4.3wt%, formaldehyde=2.2wt%); concentrated liquid 1 continues to enter the secondary membrane to concentrate, and dilute liquid 1 is collected; concentrated liquid 1 passes through the secondary After the membrane is concentrated, it is divided into two parts, the strong liquid 2 and the weak liquid 2. In the strong liquid 2 (glyphosate=6.6wt%, formaldehyde=3.4wt%), the light liquid 2 is collected; the strong liquid 2 continues to enter the three-stage membrane concentration; It is further divided into two parts, the thick liquid 3 and the thin liquid 3. In the thick liquid 3 (glyphos...

Embodiment 3

[0042] Take 1200g of the glyphosate concentrated mother liquor (glyphosate=5.2wt%, formaldehyde=4.5wt%) left after concentrating and powdering according to Example 1, add 98% urea 55.1g according to the ratio of formaldehyde and urea 1:0.5 , heated up to 75-80°C, and the heat preservation reaction was completed for 1.0h; cooled to normal temperature, filtered, and the precipitate was removed to obtain a concentrated mother liquor of glyphosate with low formaldehyde content, and the formaldehyde content was analyzed to be 0.056wt%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com