Method for preparing synthesized polymer aluminum sulphate through spent catalyst

A technology of polymerizing aluminum sulfate and waste catalysts, applied in the direction of aluminum sulfate, aluminum sulfur compounds, etc., can solve pollution and other problems, achieve the effect of reducing production costs and making treatment difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

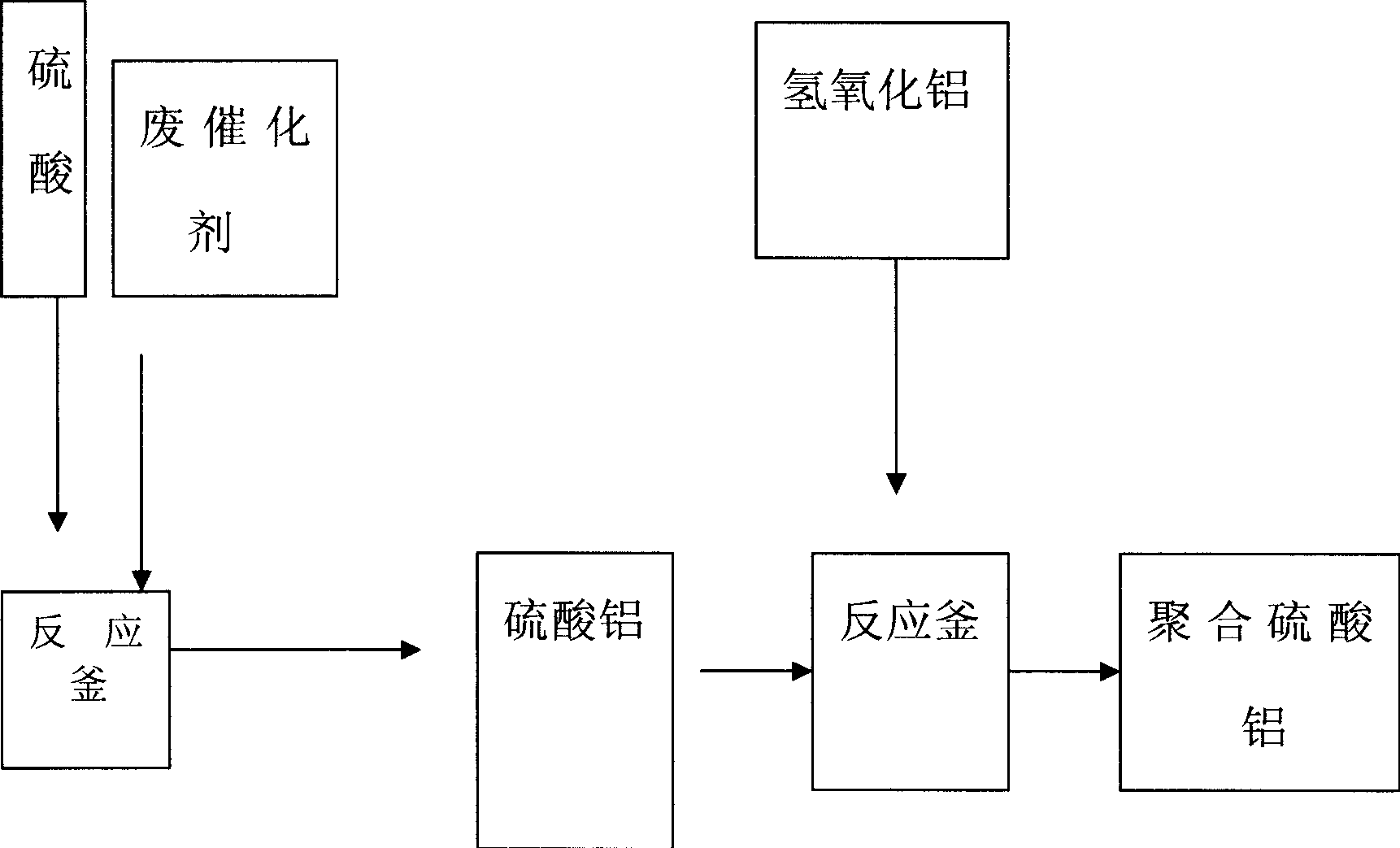

[0016] 1. Preparation of aluminum sulfate

[0017] The factors affecting the dissolution rate of aluminum sulfate are mainly the concentration of sulfuric acid, the ratio of spent catalyst to sulfuric acid and the reaction temperature. The most significant factor affecting the dissolution rate of aluminum salt is the ratio of spent catalyst to sulfuric acid. According to many tests, the optimal reaction conditions were selected as follows: the concentration of sulfuric acid was 3%, and the reaction temperature was 85°C. The weight ratio of spent catalyst to sulfuric acid is preferably 1:10, and the reaction time is 1 hour.

[0018] 2. Preparation of polyaluminum sulfate liquid product

[0019] In the preparation of polyaluminum sulfate, the most significant factor affecting the polymerization is the equivalent ratio of aluminum sulfate and aluminum hydroxide. According to many tests, the optimal reaction conditions were selected as follows: when the equivalent ratio of alum...

Embodiment 1

[0020] Embodiment 1: (calculated by 100 grams of spent catalyst)

[0021] Add 100 grams of spent catalyst into a reactor with heating and stirring functions. Then add 1000 grams of sulfuric acid with a concentration of 3%, the reaction temperature is 85° C., and the reaction time is 1 hour. Filter to obtain liquid aluminum sulfate. Put the liquid aluminum sulfate back into the reactor, add 150 grams of 5% aluminum hydroxide, and stir for 1 hour to obtain 1120 grams of liquid polyaluminum sulfate product.

Embodiment 2

[0022] Embodiment 2: (calculated by 100 grams of spent catalyst)

[0023] Add 100 grams of wax oil catalytic waste catalyst in the reaction kettle with heating and stirring. Then add 600 grams of sulfuric acid with a concentration of 5%, the reaction temperature is 90° C., and the reaction time is 1 hour. Filter to obtain liquid aluminum sulfate. The liquid aluminum sulfate was put back into the reactor, and 230 milliliters of 7% aluminum hydroxide was added, and then stirred for 1 hour to obtain 800 grams of liquid polyaluminum sulfate product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com